Cu/Co@NPC compound used for catalytic reduction of p-nitrophenol

A technology of p-nitrophenol and p-aminophenol, applied in chemical/physical processes, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as poor catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

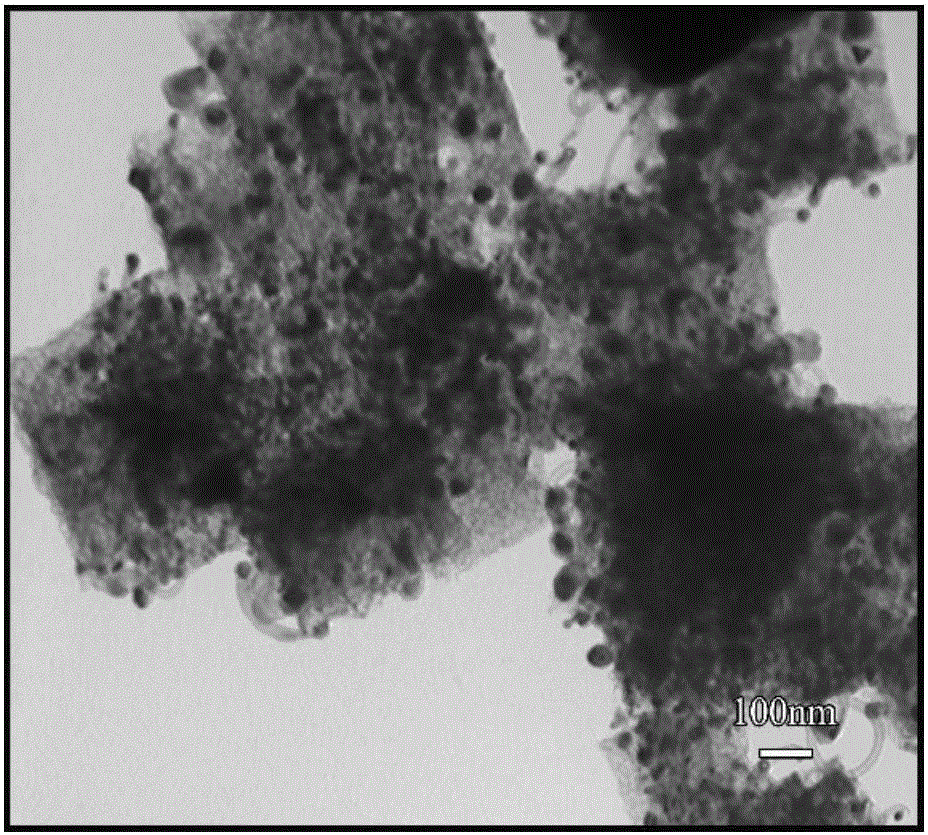

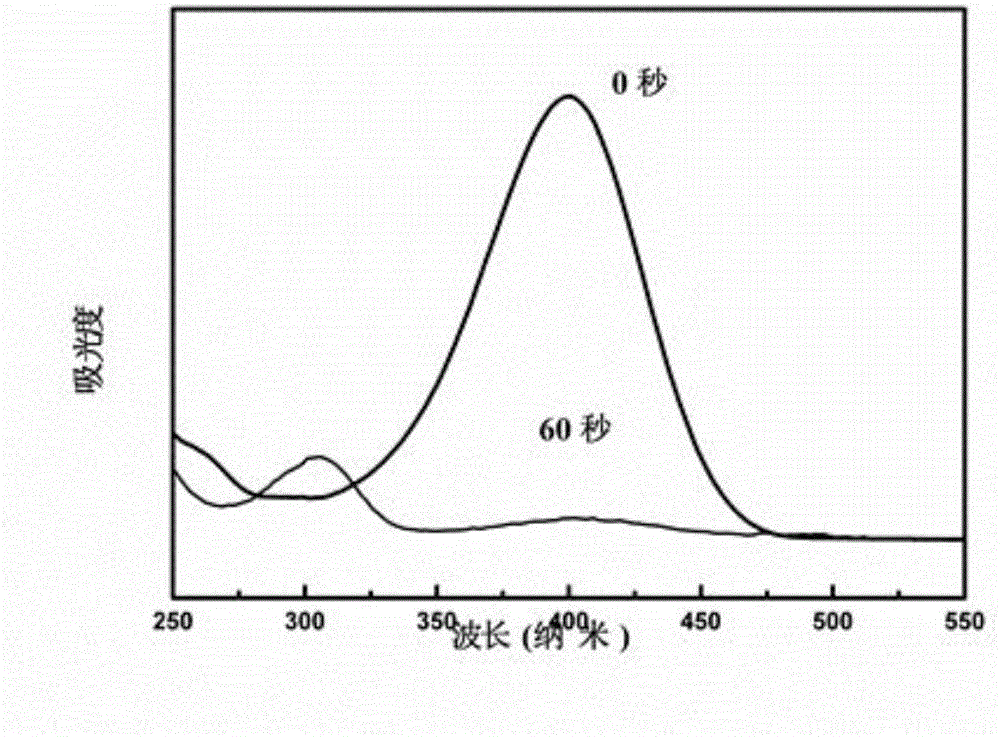

[0014] Example 1: 0.6 mmol Cu(NO 3 ) 2 ·3H 2 O, 0.9 mmol Na 3 C 6 h 5 o 7 2H 2 O was dissolved in 15 mL deionized water, and another 0.4 mmol K 3 [Co(CN) 6 ] dissolved in 15 mL deionized water, the above two solutions were quickly mixed, and aged at room temperature for 24 h. Centrifuged to get solid powder, this solid powder was washed several times with deionized water and ethanol respectively, 60 o C Vacuum dried. The dried solid powder was dried in a tube furnace with an Ar atmosphere of 600 o C roasting for 3 h with a heating rate of 2 o C·min -1 , see attached figure 1 To attach Figure 5 .

Embodiment 2

[0015] Example 2: 0.6 mmol CuCl 2 2H 2 O, 0.9 mmol Na 3 C 6 h 5 o 7 2H 2 O was dissolved in 15 mL deionized water, and another 0.4 mmol K 3 [Co(CN) 6 ] dissolved in 15 mL deionized water, the above two solutions were quickly mixed, and aged at room temperature for 24 h. Centrifuged to get solid powder, this solid powder was washed several times with deionized water and ethanol respectively, 60 o C Vacuum dried. The dried solid powder was dried in a tube furnace with an Ar atmosphere of 600 o C roasting for 3 h with a heating rate of 2 o C·min -1 .

Embodiment 3

[0016] Example 3: 0.6 mmol CuSO 4 ·5H 2 O, 0.9 mmol Na 3 C 6 h 5 o 7 2H 2 O was dissolved in 15 mL deionized water, and another 0.4 mmol K 3 [Co(CN) 6 ] dissolved in 15 mL deionized water, the above two solutions were quickly mixed, and aged at room temperature for 24 h. Centrifuged to get solid powder, this solid powder was washed several times with deionized water and ethanol respectively, 60 o C Vacuum dried. The dried solid powder was dried in a tube furnace with an Ar atmosphere of 600 o C roasting for 3 h with a heating rate of 2 o C·min -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com