Mountain spring water production process

A production process, mountain spring water technology, applied in multi-stage water treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as affecting the taste of natural water, residual carcinogenic negative product bromate, health threats, etc. , to prevent stones and gastrointestinal disorders, sterilize quickly and thoroughly, and improve drinking health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

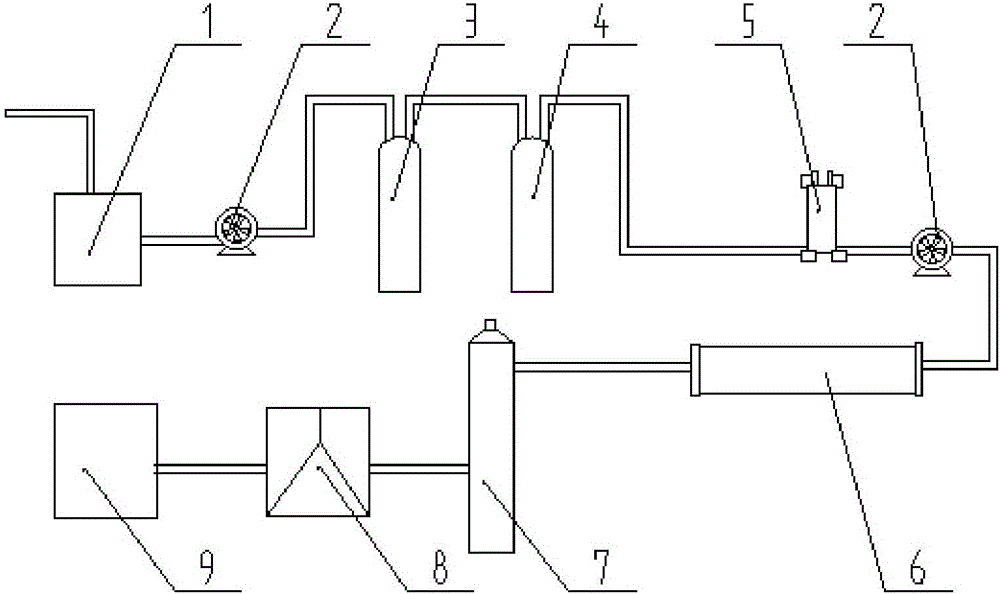

[0021] Implementation 1 of the present invention comprises the following steps:

[0022] (a) Select high-quality mountain spring water, first use a quartz sand filter to filter suspended solids, organisms, and solid particles in the water, and then use bamboo charcoal adsorbers and coconut shell activated carbon adsorbers to adsorb again, which can effectively remove organic particles and microorganisms in the water and odors in the water.

[0023] (b) Perform reverse osmosis filtration on the water treated in step (a) in the ultrafiltration water purifier 5 to remove colloidal microorganisms in the water; the pore size of the reverse osmosis membrane of the ultrafiltration water purifier 5 is 0.001-0.02 μm. The ultrafiltration water purifier 5 can effectively remove tiny particles in water.

[0024] (c) The water filtered in step (b) is put into the disinfectant through the reagent box 6 for disinfection and sterilization; the disinfectant comprises the following medicines i...

Embodiment 2

[0028] Implementation 2 of the present invention is different from Example 1 in that the disinfectant comprises the following medicines in parts by weight and is prepared from: 20 parts of chlorine dioxide solution, 2 parts of honeysuckle extract, 2 parts of isatidis extract, 1 part of camphor extract share.

[0029] Implementation 3 of the present invention is different from Example 1 in that the disinfectant comprises the following medicines in parts by weight and is prepared from: 40 parts of chlorine dioxide solution, 3 parts of honeysuckle extract, 4 parts of Radix isatidis extract, 3 parts of camphor extract share.

[0030] The process of the present invention is: instant high-temperature sterilization of mineral water by ultra-high temperature instant sterilizer 8, which has the advantage of not only being able to kill heat-resistant microbial spores but also minimizing the destruction of nutrients in mountain springs, and maintaining The taste of mountain spring water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com