Preparation method of polybenzimidazole/free radical quenching agent composite film

A polybenzimidazole and benzimidazole technology, applied in electrical components, circuits, battery pack components and other directions, can solve problems such as battery performance decline, aggravate PBI film degradation, etc., achieve high electrical conductivity, improve chemical stability and Durability, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 0.2203g of PBI resin, dissolve it in 19.2668g of NMP, stir for 12h, and filter twice with suction to remove impurities. Weigh 0.0045gCeO 2 , added to the PBI solution, stirred for 1 h, and sonicated for 2 h. PBI / CeO 2 Pour the casting liquid into a 9*10cm mold, and keep it in a drying oven at 80°C for 24 hours to obtain uniform and dense PBI / CeO 2 Composite film. Cut a composite film with a thickness of 36 μm to a size of 3.5*3.5 cm and a mass of 0.0441 g. Immerse in 80wt.% phosphoric acid at 80°C for 24 hours. After taking out the membrane, blot the excess acid on the surface of the membrane with filter paper, weigh it, and prepare the PBI / CeO 2 - The mass of the PA composite membrane is 0.1358g, and the phosphoric acid loading is 2.08. The length and width elongation of the composite film were both 12.5%.

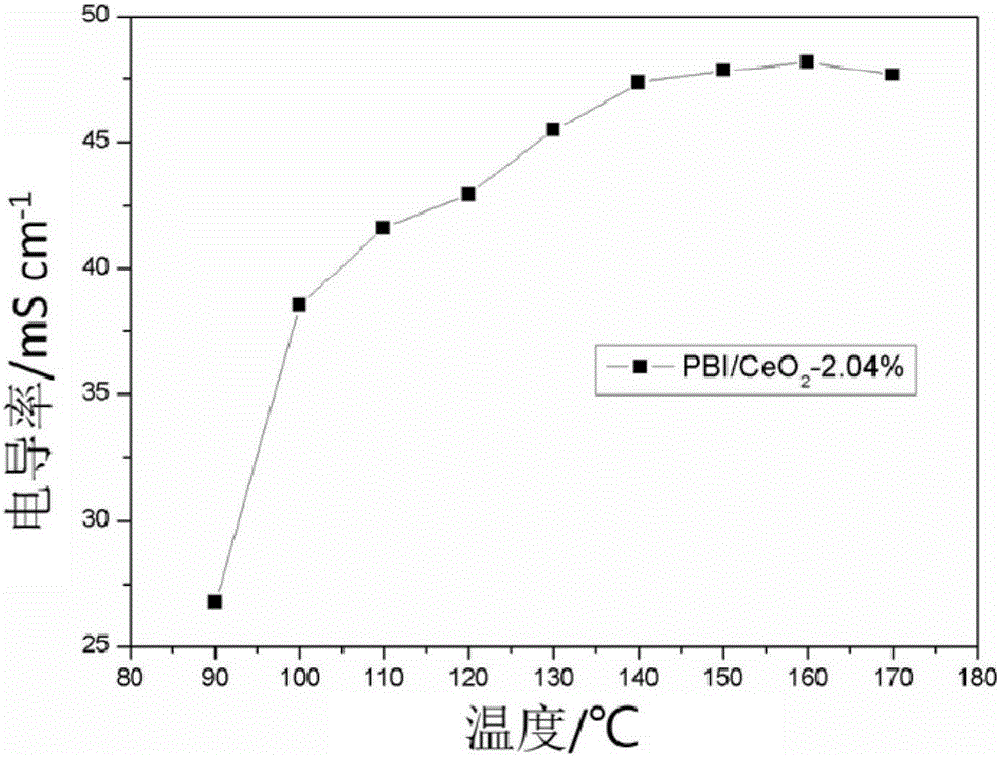

[0036] PBI / CeO 2 -CeO in PA composite film 2 The load is 2.04%.

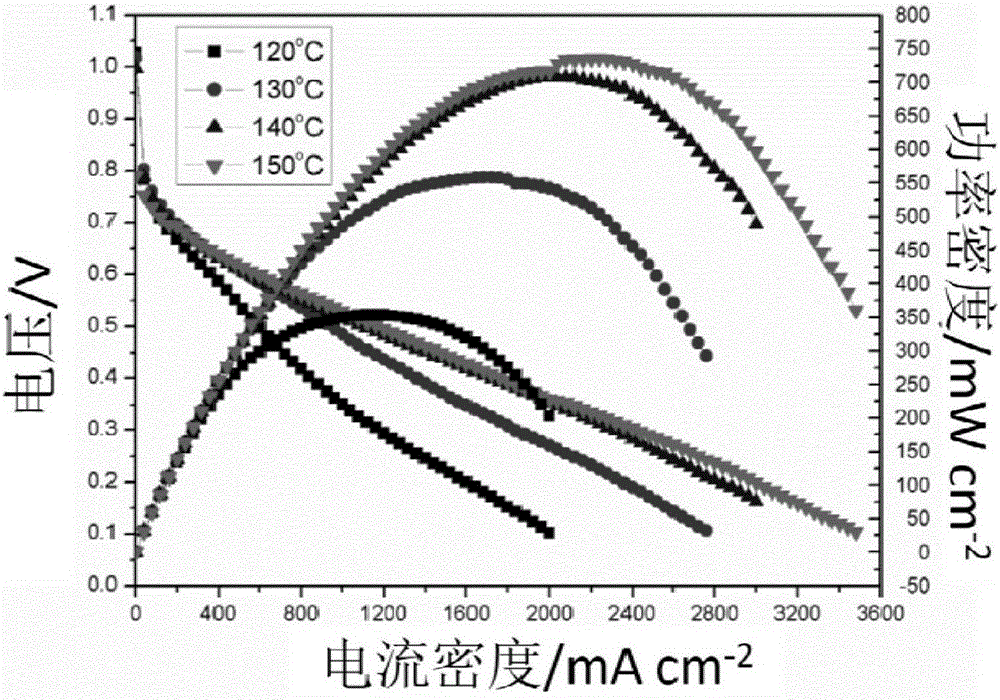

[0037] Testing PBI / CeO by Impedance Impedance Method (EIS) 2 -The electrical con...

Embodiment 2

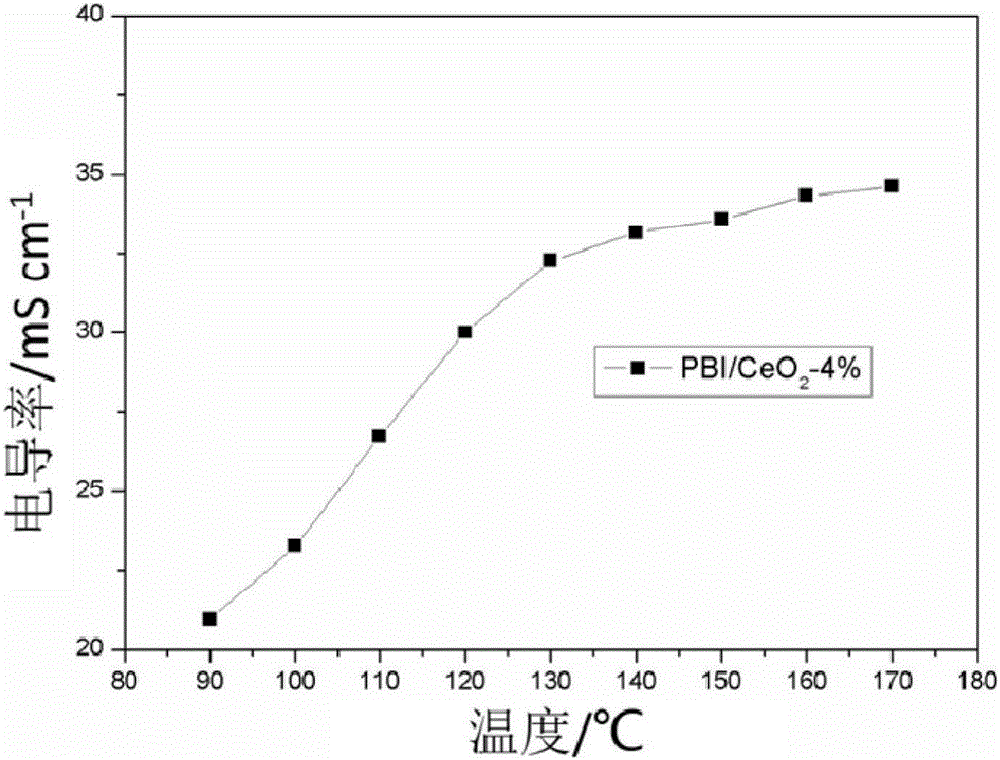

[0039] Weigh 0.2103g of PBI resin, dissolve in 20g of NMP, stir for 12h, and filter twice with suction to remove impurities. Weigh 0.0084gCeO 2 , added to the PBI solution, stirred for 1 h, and sonicated for 2 h. PBI / CeO 2 Pour the casting liquid into a 9*10cm mold, and keep it in a drying oven at 80°C for 24 hours to obtain uniform and dense PBI / CeO 2 Composite film. Cut a composite film with a thickness of 30 μm to a size of 4*4cm and a mass of 0.0440g. Immerse in 80wt.% phosphoric acid at 80°C for 24 hours. After taking out the membrane, blot the excess acid on the surface of the membrane with filter paper, weigh it, and prepare the PBI / CeO 2 - The mass of the PA composite film is 0.1423g, the thickness becomes 50μm, and the phosphoric acid loading is 2.23. The length and width elongation of the composite film were both 25%. PBI / CeO 2 -CeO in PA composite film 2 The load is 4.0%.

[0040] Testing PBI / CeO by Impedance Impedance Method (EIS) 2 -The electrical condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com