Transparent basis lacquer of color-changing PU dream-color wood lacquer

A wood lacquer and color-changing technology, applied in the coating and other directions, can solve the problems of dull gloss, poor flexibility, and inability to increase the hardness too much, and achieve the effect of high gloss, high hardness and high cross-linking degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of above-mentioned transparent base varnish comprises the following steps:

[0025] A. Select a clean and standard dispersion cylinder;

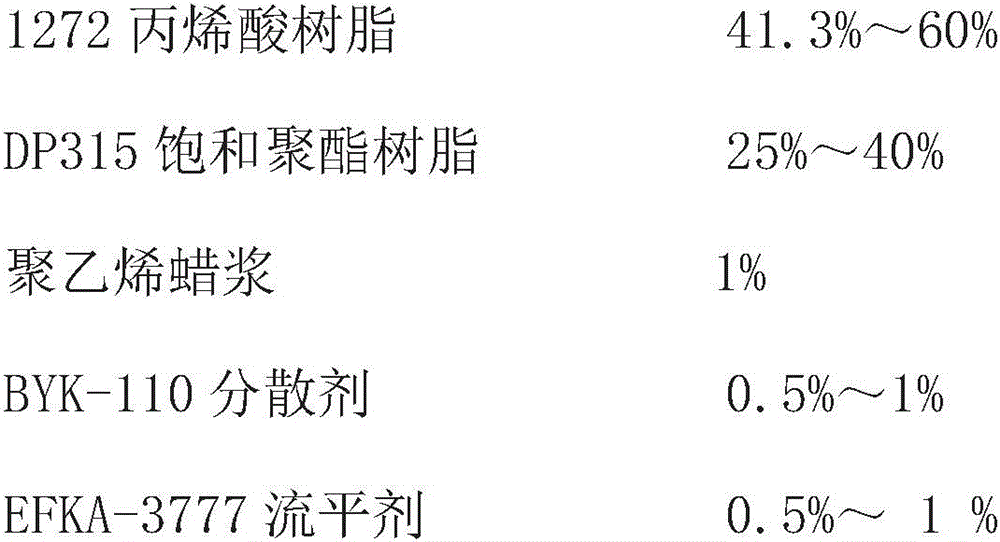

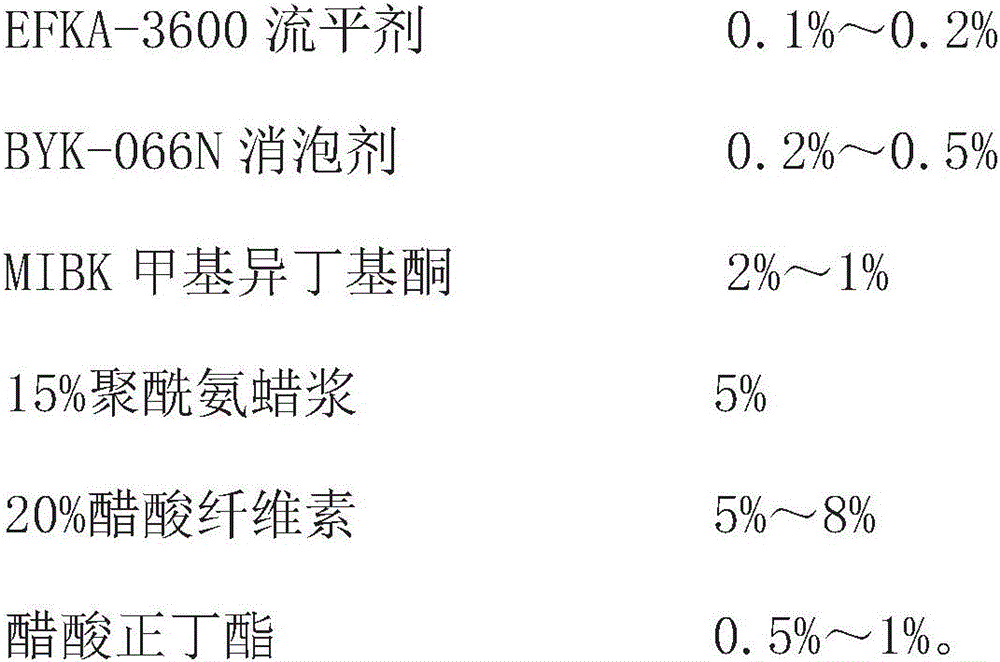

[0026] B. Put in 1272 acrylic resin 41.3%~60%, DP315 saturated polyester resin 25%~40%, polyethylene wax paste 1%, BYK-110 dispersant 0.5%~1%, EFKA-3777 leveling agent 0.5% ~1%, EFKA-3600 leveling agent 0.1%~0.2%, BYK-066N defoamer 0.2%~0.5%, MIBK methyl isobutyl ketone 2%~1%;

[0027] C. Start the disperser and disperse at low speed (1200-1500r / min) for 10 minutes;

[0028] D. Add 5% of 15% polyamide wax slurry, 5% to 8% of 20% cellulose acetate, release no less than 2KG paint at the interface, pour it back into the dispersion tank, and send it for inspection after it is evenly dispersed;

[0029] E. Add 0.5% to 1% of n-butyl acetate to adjust the viscosity to 2500 to 3500mpa.s / 25°C to obtain a transparent base varnish of component A.

[0030] Among them, 1272: High-hydroxyl acrylic resin produced by New Pac...

Embodiment 1

[0053] 1) Preparation of 20% cellulose acetate:

[0054] Methyl ethyl ketone 20Kg

[0055] CAB-551-0.2 20Kg

[0056] Butyl acetate 60Kg

[0057] Disperse and stir until completely dissolved, until the fineness is ≤15um;

[0058] 2) Proportion of component A transparent base varnish:

[0059]

[0060] Uniform dispersion to fineness≤25um, viscosity 2500~3500mpa.s / 25℃

[0061] 3) Proportion of component A magic paint:

[0062] Base paint 80Kg

[0063] Color-changing pearlescent pigment 20Kg

[0064] 4) The ratio of component B:

[0065]

[0066] After dehydration, start stirring and dispersing for 30 minutes, keep warm at 70°C, cool down and discharge and seal.

[0067] HI-100: 100% solid HDI trimer curing agent produced by BASF (China) Co., Ltd.;

[0068] 3390: 90% solid HDI trimer curing agent produced by Bayer;

[0069] 5) The ratio of component C

[0070]

[0071] Stir well and set aside

[0072] The preparation of described component A transparent base v...

Embodiment 2

[0079] 1) Preparation of 20% cellulose acetate:

[0080] Methyl ethyl ketone 20Kg

[0081] CAB-551-0.2 20Kg

[0082] Butyl acetate 60Kg

[0083] Disperse and stir until completely dissolved, until the fineness is ≤15um;

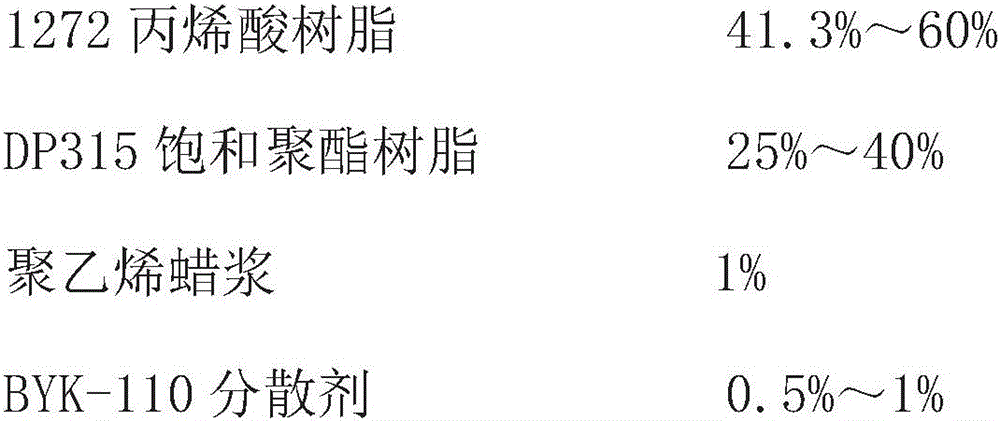

[0084] 2) Proportion of component A transparent base varnish:

[0085]

[0086]

[0087] Uniform dispersion to fineness≤25um, viscosity 2500~3500mpa.s / 25℃

[0088] 3) Proportion of component A magic paint:

[0089] Base paint 92Kg

[0090] Color-changing pearlescent pigment 8Kg

[0091] 4) The ratio of component B:

[0092]

[0093] After dehydration, start stirring and dispersing for 30 minutes, keep warm at 70°C, cool down and discharge and seal.

[0094] HI-100: 100% solid HDI trimer curing agent produced by BASF (China) Co., Ltd.;

[0095] 3390: 90% solid HDI trimer curing agent produced by Bayer;

[0096] 5) The ratio of component C

[0097]

[0098] Stir well and set aside

[0099] The preparation of described component A transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com