Composite Strengthening Treatment Method of Omnidirectional Ion Implantation and Deposition on the Surface of Titanium Alloy Parts

A technology of ion implantation and strengthening treatment, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as poor bonding force and bearing capacity, easy peeling from the titanium alloy substrate, and large residual stress , to achieve the effect of strong bearing capacity, excellent compactness and bonding force, and excellent surface properties

Inactive Publication Date: 2010-12-15

SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In view of the above-mentioned deficiencies in the prior art, the technical problem to be solved by the present invention is to overcome the defects and deficiencies of large residual stress between the surface anti-wear layer and the titanium alloy part substrate, poor bonding force and bearing capacity, and easy peeling off from the titanium alloy substrate. Provided is a composite strengthening treatment method of omni-directional ion implantation and deposition on the surface of titanium alloy parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

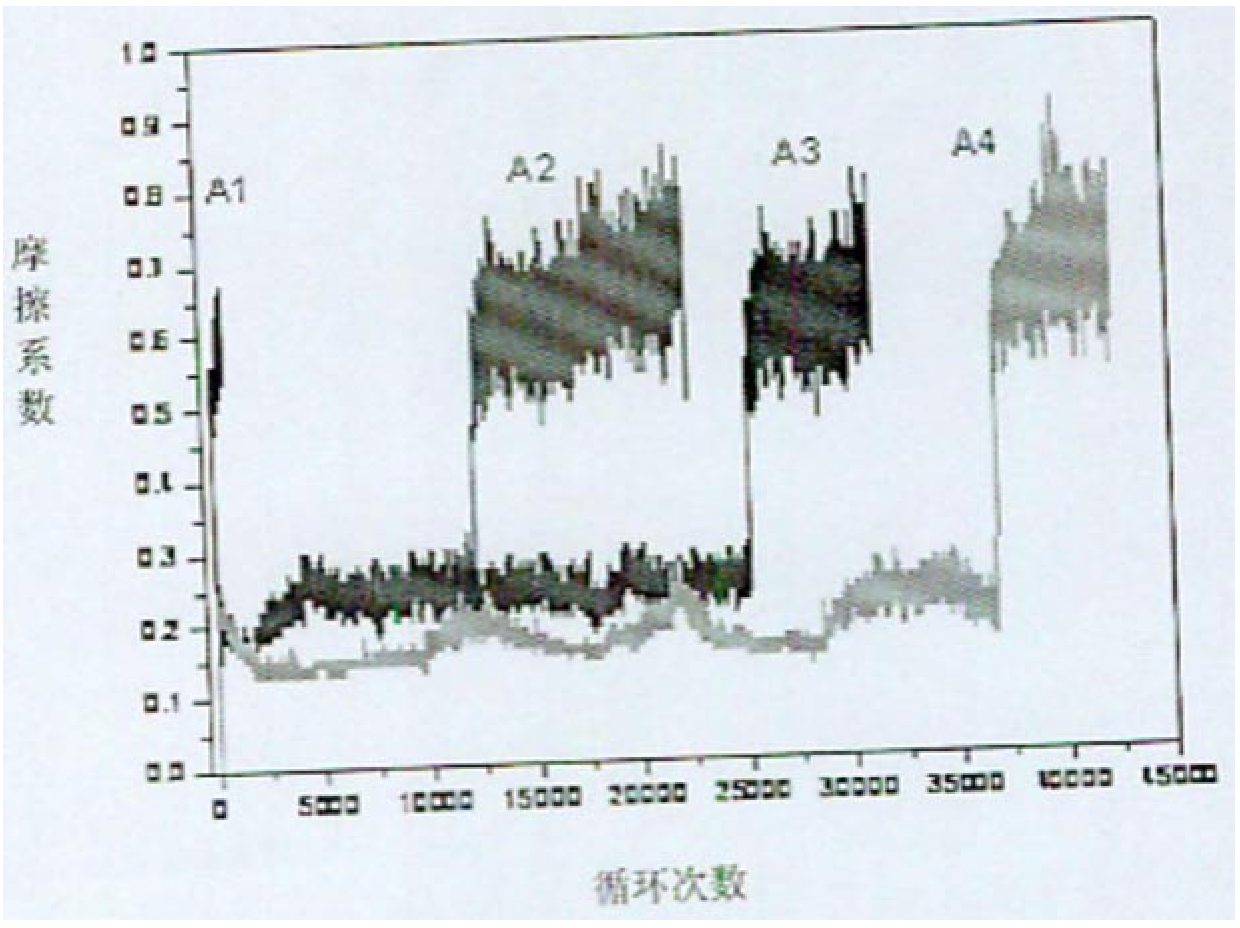

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Login to View More

Abstract

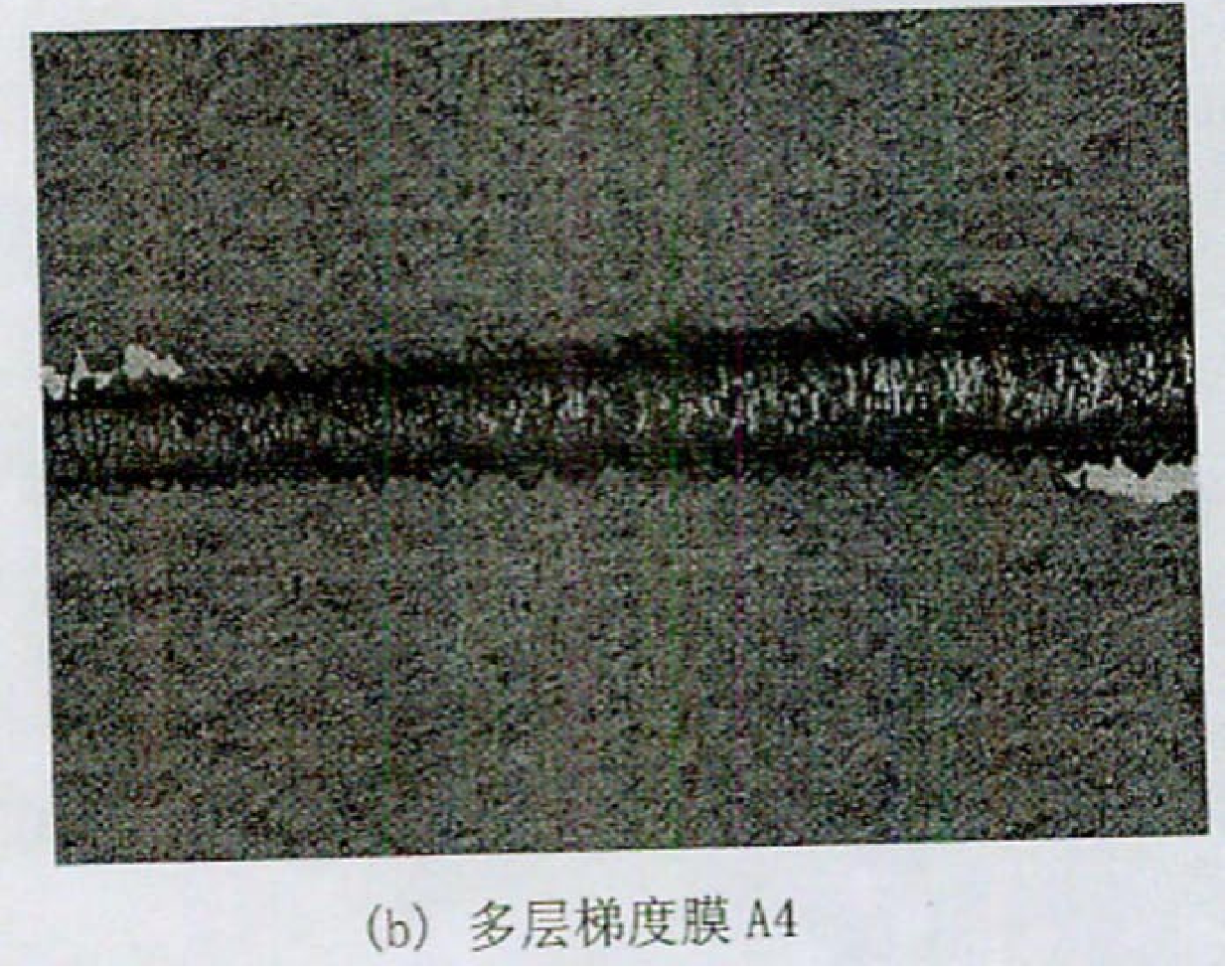

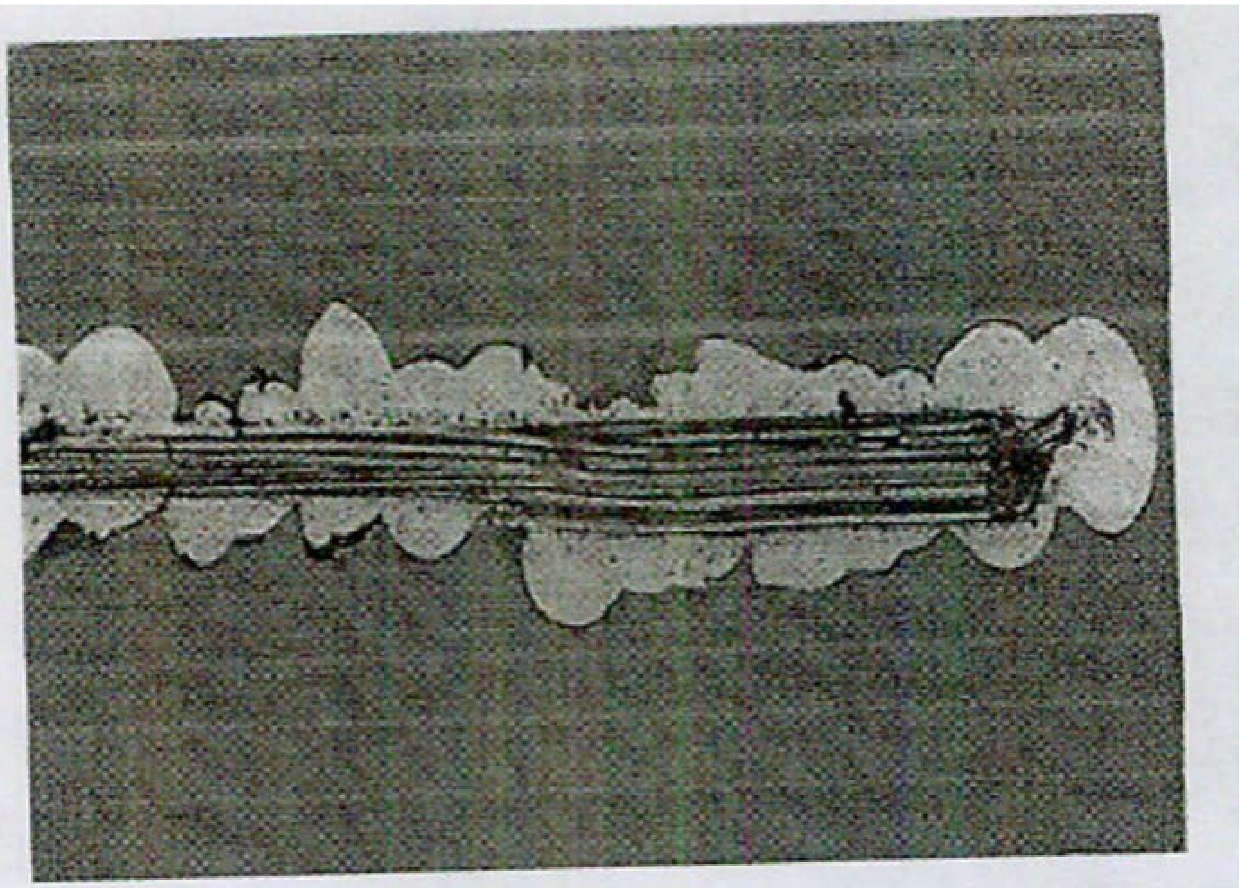

The invention discloses a comprehensive strengthening treatment method of omnidirectional ion implantation and deposition on the surface of a titanium alloy part, which relates to a method for comprehensive ion implantation and deposition strengthening treatment of the surface of a metal material. It solves the problem of large residual stress between the surface anti-wear layer and the titanium alloy part matrix, poor bonding force and bearing capacity, and easy peeling off from the titanium alloy matrix. The synthesis method is carried out according to the following steps: (1) ultrasonic cleaning of titanium alloy parts; (2) argon ion sputtering cleaning of titanium alloy parts; (3) gas ion implantation; (4) deposition of TiN by PIII&D method; (5) deposition of Ti by PIII&D method (CN); (6) TiC deposited by PIII&D method; (7) synthesizing a diamond-like carbon film or MoS2 film to obtain a titanium alloy part with a composite strengthening layer structure on the surface; steps (2) to (7) are carried out in a vacuum chamber. The wear life of the DLC on the composite strengthening layer in the present invention is more than 10 times higher than that of a single-layer DLC with the same thickness, and the friction coefficient is lower than 0.1.

Description

Composite Strengthening Treatment Method of Omnidirectional Ion Implantation and Deposition on the Surface of Titanium Alloy Parts technical field The invention relates to a method for all-round ion implantation and deposition strengthening treatment on the surface of a metal material. Background technique Titanium alloys have high specific strength, good corrosion resistance, and stable mechanical properties at moderate temperatures. They have been widely used in aerospace, aviation, chemical and biomedical fields. However, the wear resistance of titanium alloy is poor, and it is very sensitive to adhesive wear and fretting wear, which seriously affects the safety and reliability of titanium alloy parts and limits its application. It is necessary to adopt a reliable surface strengthening technology to realize the anti-wear strengthening treatment of the surface of titanium alloy parts. The all-round ion implantation and deposition (abroad called plasma immersion ion imp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C14/48C23C14/02C23C14/16C23C14/54

Inventor 王炜庄纯王浪平徐小明邱颖光

Owner SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com