Aluminum copper dissimilar metal rotation friction welding method added with middle layer

A technology of rotary friction welding and dissimilar metals, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problem of low joint strength, achieve short welding time, increase joint strength, and low welding temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

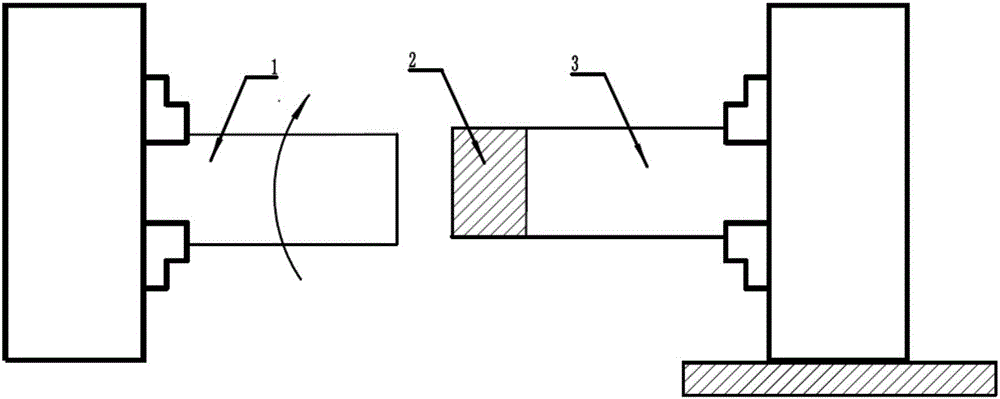

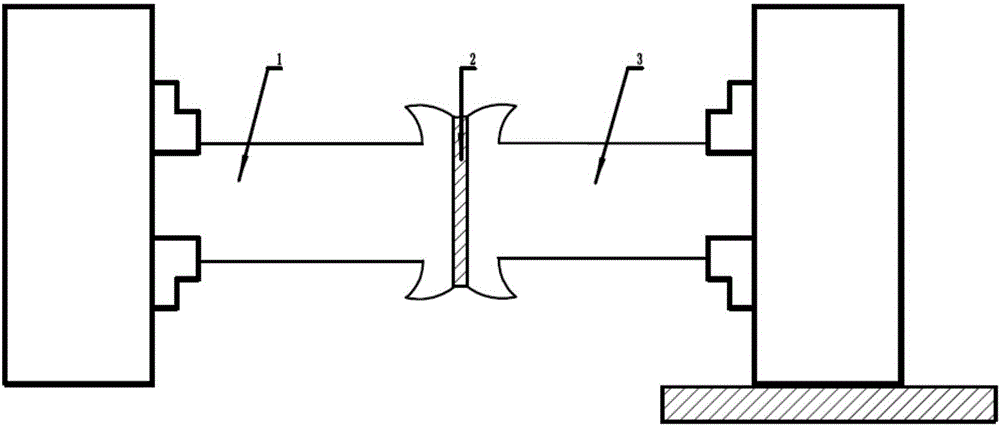

[0019] Embodiment 1: Rotary friction welding of 1100 pure aluminum and T2 red copper with ZAMAK3 zinc alloy intermediate layer.

[0020] Step 1. Spin friction welding of 1100 pure aluminum and ZAMAK3 zinc alloy intermediate layer.

[0021] 1100 pure aluminum 1 is a bar with a diameter of 20mm and a length of 90mm, and ZAMAK3 zinc alloy 2 is a bar with a diameter of 20mm and a length of 60mm. Fine grinding shall be carried out before welding. When welding, first clamp 1100 pure aluminum 1 to the fixed end of the friction welding machine, clamp ZAMAK3 zinc alloy 2 to the rotating end, set the welding parameters as follows: welding speed 1500rpm, welding pressure 60MPa, axial shortening 5mm, top The forging pressure is 100MPa, and the upsetting time is 6s. After welding, wire cutting is used to process the aluminum and zinc joints, retaining the zinc alloy layer 2 with a length of 5 mm, and grinding the zinc alloy end face.

[0022] Step 2. Rotary friction welding of 1100 pure...

Embodiment 2

[0025] Embodiment 2: Spin friction welding of 7050 aluminum alloy and T2 red copper with nickel intermediate layer.

[0026] Step 1. Welding of 7050 aluminum alloy and nickel metal.

[0027] The 7050 aluminum alloy 1 is a bar with a diameter of 20 mm and a length of 90 mm, and the nickel metal 2 is a bar with a diameter of 20 mm and a length of 60 mm. Fine grinding shall be carried out before welding. When welding, first clamp the 7050 aluminum alloy 1 to the fixed end of the friction welding machine, and clamp the nickel metal 2 to the rotating end of the friction welding machine, set the welding parameters as follows: welding speed 1200rpm, welding pressure 80MPa, axial shortening 5mm , upsetting pressure 110MPa, upsetting time 4s. After welding, wire cutting is used to process the joint, and the nickel metal 2 with a length of 5 mm is reserved, and the end face is ground.

[0028] Step 2. Rotary friction welding of 7050 aluminum alloy with intermediate layer and T2 red c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com