A method for reusing ferric chloride corrosion solution in gravure printing plate

A technology of ferric chloride and corrosive liquid in the plate, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of wastewater treatment equipment not working normally, polluting the environment, Waste of resources and other issues, to achieve the effect of being conducive to automatic production, protecting the environment, and solving waste liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

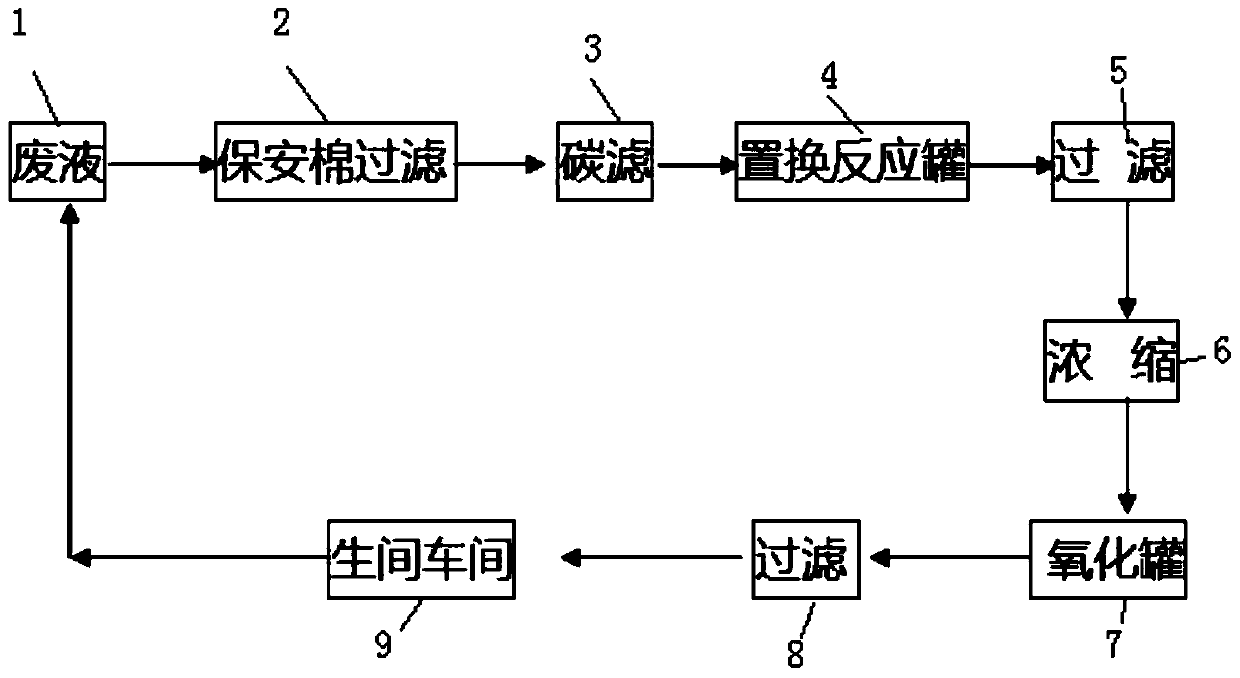

[0027] Such as figure 1 Shown, a kind of reuse method of ferric chloride corrosion solution in gravure printing plate, this method comprises the following steps:

[0028] (1) Primary filtration: pass the waste liquid 1 through the security cotton filter 2 to remove impurities and particles; the filter core of the security cotton filter is 5um.

[0029] (2) Carbon filter 3: Filter the filtrate after primary filtration through activated carbon to remove the glue in the waste liquid; during the corrosion process, the glue on the plate roller will be brought into the waste liquid, and some glue will be decomposed and converted into grease, It has a great impact on the post-processing (the main phenomenon is that the ferric iron is easily decomposed during the concentration process of ferric trichloride, resulting in the precipitation of ferric hydroxide). The use of activated carbon adsorption can effectively reduce this problem.

[0030] (3) Replacement reaction: Add reduced ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com