Spatlese sweet white wine and preparing method thereof

A technology for white wine and production method, applied in the field of fermentation technology, can solve the problems of poor sensory quality and complex brewing process of sweet white wine, and achieve the effects of reduced loss, enhanced floral and mineral characteristics, and overall complex and elegant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

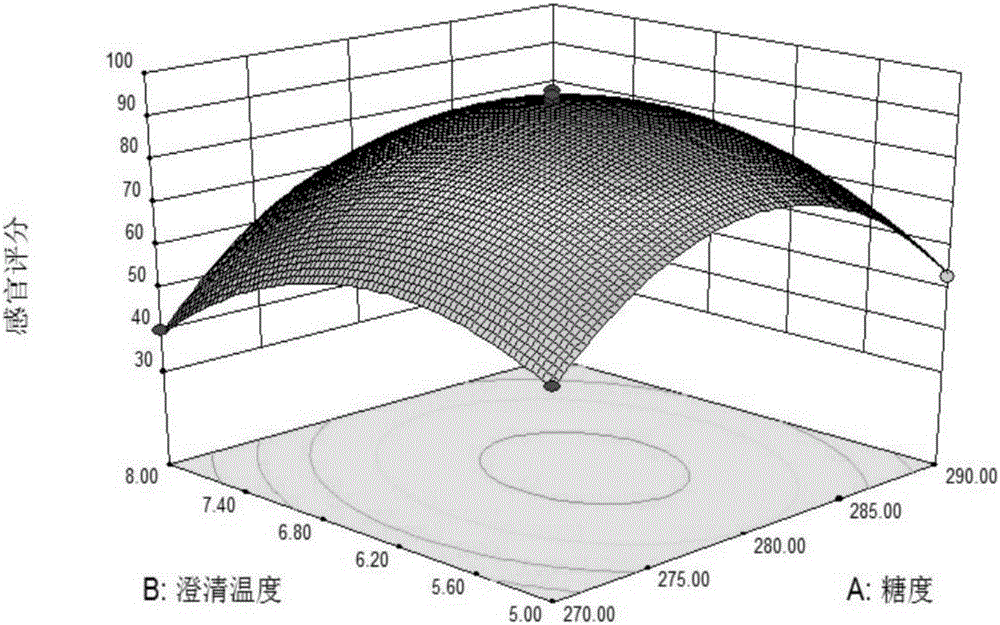

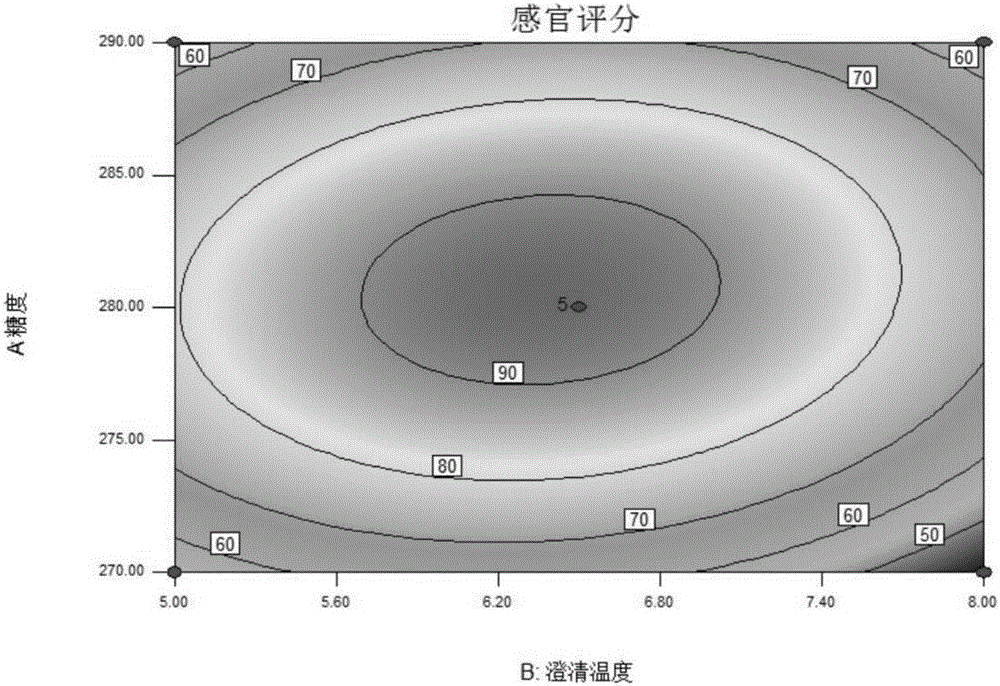

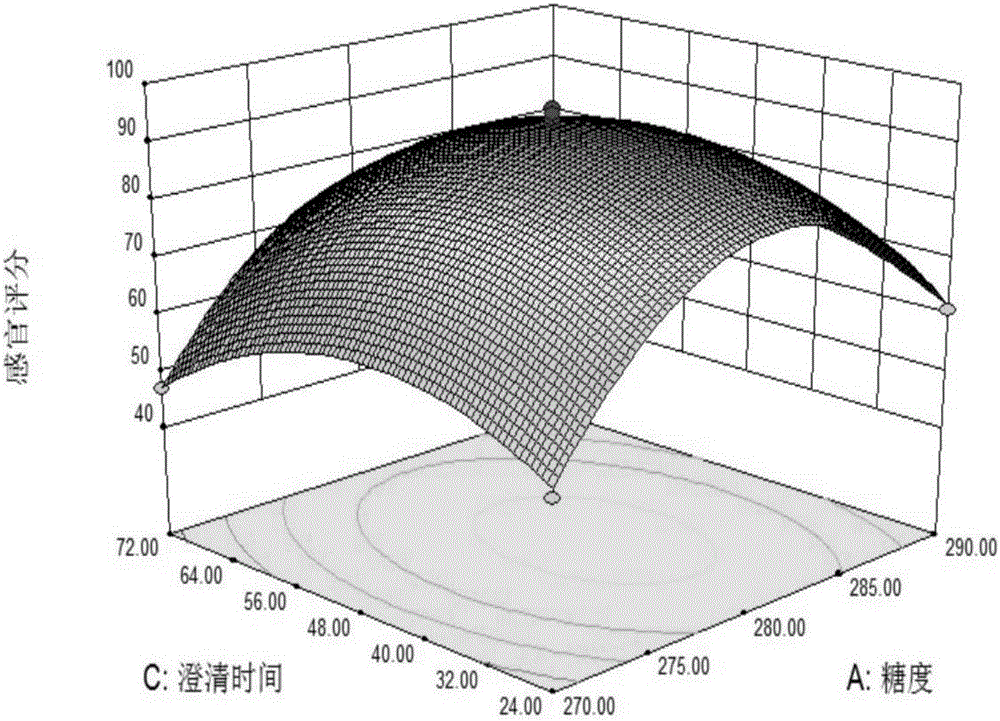

[0051] The concrete steps that the preparation method of late picking sweet white wine adopts are as follows:

[0052] (1) Raw material selection: use specific Riesling and Verdy grape varieties, and on the basis of the normal maturity of the grapes, the harvest is postponed for one month, and the sugar content of the grapes is required to reach 270-290g / L at the time of harvest.

[0053] (2) Sorting of raw materials: Grapes are sorted by a sorting machine to remove mildew, diseased and damaged raw materials, and to select grapes with plump and tidy particles and uniform color.

[0054] (3) Destemming and crushing: adopt grape destemming crusher to carry out destemming and crushing to the sorted grapes, the crushing rate is 0, add sulfurous acid 40ppm when destemming and crushing, that is, 0.67kg sulfurous acid / ton of grapes, pectinase Appropriate amount.

[0055] (4) Air bag press: the grapes processed in the above steps enter the air bag press, and are protected by inert ga...

Embodiment 2

[0070] On the basis of the normal ripening of the grapes, the harvesting is postponed for one month, and the sugar content of the grapes is required to reach 270g / L at the time of harvesting. The grapes are sorted by a sorting machine to remove mildew, diseased and damaged raw materials. For grapes with plump and neat particles and uniform color, use a grape destemming crusher to destem and crush the sorted grapes. The crushing rate is 0. When destemming and crushing, add 40 ppm of sulfurous acid and an appropriate amount of pectinase; The grapes enter the air bag press, and use inert gas for protection, and press under the pressure of less than 0.1bar. It is required not to crush the skin seeds, and the press is not too dry. Put the clear juice into the tank, and add 20ppm of sulfurous acid during the process to prevent the oxidation of the clear juice; after the clear juice is put into the tank, add tartaric acid to 7.0g / L, add 50ppm of compound clarification enzyme to the cl...

Embodiment 3

[0072] On the basis of the normal ripening of the grapes, the harvesting is postponed for one month, and the sugar content of the grapes is required to reach 280g / L at the time of harvesting. The grapes are sorted by a sorting machine to remove mildew, diseased and damaged raw materials. For grapes with plump and neat particles and uniform color, use a grape destemming crusher to destem and crush the sorted grapes. The crushing rate is 0. When destemming and crushing, add 40 ppm of sulfurous acid and an appropriate amount of pectinase; The grapes enter the air bag press, and use inert gas for protection, and press under the pressure of less than 0.1bar. It is required not to crush the skin seeds, and the press is not too dry. The clear juice is put into the tank, and 20ppm of sulfurous acid is added during the process to prevent the oxidation of the clear juice; after the clear juice is put into the tank, tartaric acid is added to 7.0g / L, and 50ppm of compound clarification enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com