Foaming and pumping system for physical foaming foam concrete

A foamed concrete and physical foaming technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of inability to realize the lightweight material of foamed concrete, and achieve the effect of exerting practical value, fine foam and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

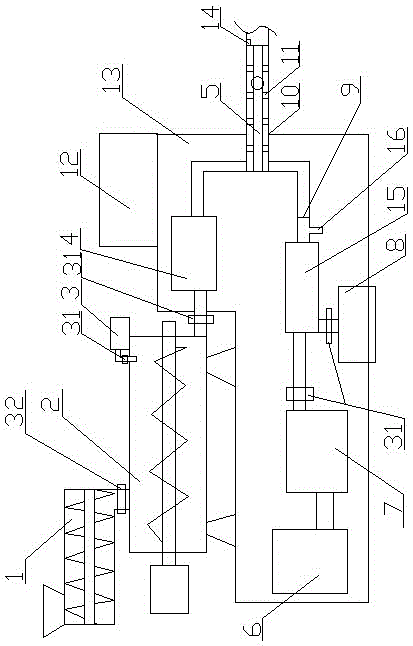

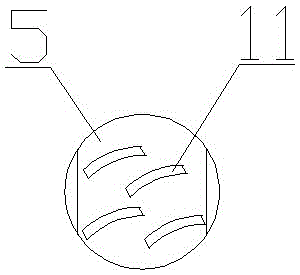

[0031] Embodiment one: if Figure 1-2 Shown: Physically foamed foam concrete foaming pumping system, including a frame with a foam concrete mixing conveying mechanism, a foam making mechanism, a cement slurry mixing mechanism and a controller inside, and the foam making mechanism and the cement slurry mixing mechanism are respectively connected to the The foam concrete mixing and conveying mechanism is connected, and the foam making mechanism, the cement mixing mechanism and the foam concrete mixing and conveying mechanism are connected to the controller 12 respectively.

[0032] Described foam making mechanism comprises piston pump 7, foam agent dilution container 6, air compressor 8 and foamer 15, and described foam agent dilution container 6 is connected with foamer 15 rear end by piston pump 7, so The air compressor 8 is connected to the lower end of the foamer 15, and the upper end of the foamer 15 is respectively provided with a foaming agent outlet 9 and a foam test out...

Embodiment 2

[0040] Embodiment two: if Figure 1-2Shown: Physically foamed foam concrete foaming pumping system, including a frame with a foam concrete mixing conveying mechanism, a foam making mechanism, a cement slurry mixing mechanism and a controller inside, and the foam making mechanism and the cement slurry mixing mechanism are respectively connected to the The foam concrete mixing and conveying mechanism is connected, and the foam making mechanism, the cement mixing mechanism and the foam concrete mixing and conveying mechanism are connected to the controller 12 respectively.

[0041] Described foam making mechanism comprises piston pump 7, foam agent dilution container 6, air compressor 8 and foamer 15, and described foam agent dilution container 6 is connected with foamer 15 rear end by piston pump 7, so The air compressor 8 is connected to the lower end of the foamer 15, and the upper end of the foamer 15 is respectively provided with a foaming agent outlet 9 and a foam test outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com