Black tea making process

A processing technology and technology for black tea, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of increasing the complexity of black tea processing machinery, failing to use water, etc., and achieve the effects of improving the sliver rate, meeting the fermentation requirements and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of black tea processing technology, comprises the following steps:

[0032] (1), tea picking: pick 1 bud and 2 leaves on the tea tree, and fresh leaves free of diseases and insect pests are used for later use;

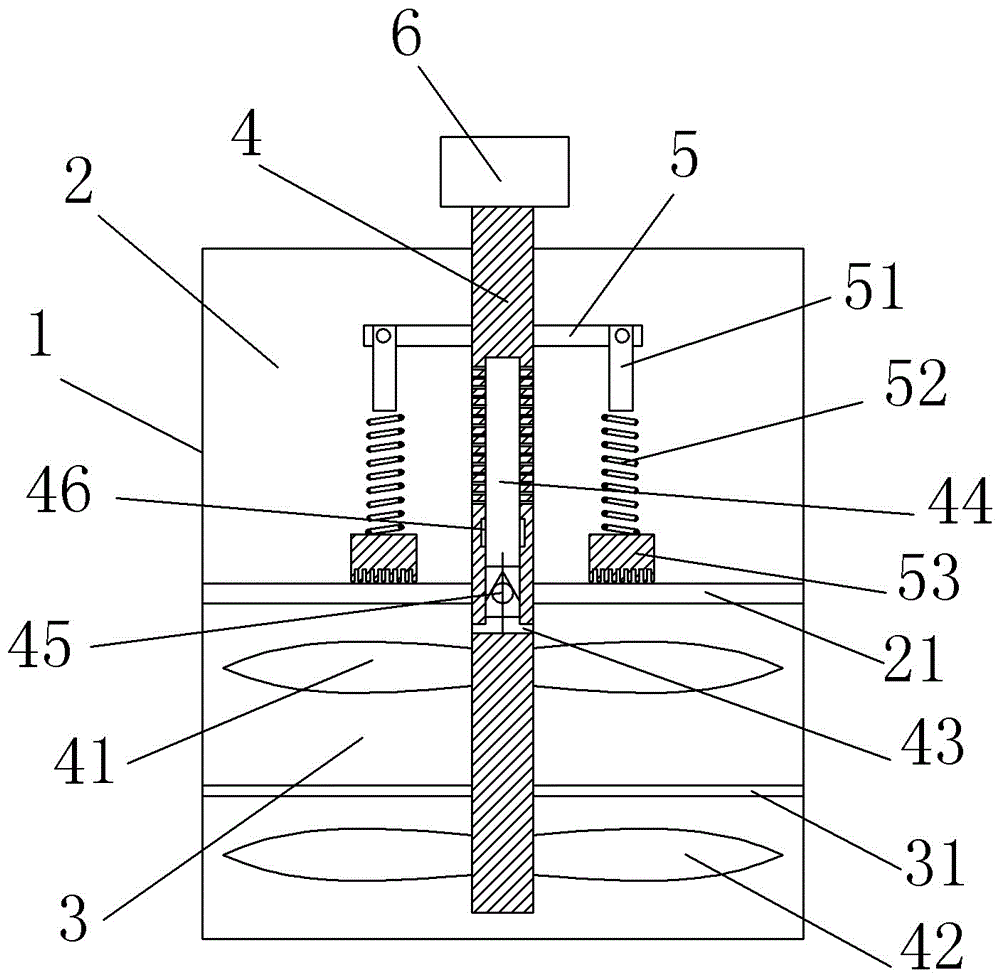

[0033](2) Withering fermentation: put the fresh leaves picked in step (1) in the withering chamber of the body, the thickness of the spread tea is 12cm, put the withered black tea in the fermentation chamber of the body, the thickness of the spread tea is 15cm, start Frequency conversion motor, the power supply frequency of the frequency conversion motor is 50Hz, and the speed of the frequency conversion motor is 1500r / min. The frequency conversion motor drives the rotating plate, the first fan and the second fan to rotate simultaneously through the rotating shaft, and the airflow generated by the rotation of the second fan enters through the through hole In the withering room, when the first fan rotates, a negative pressure will be formed at the center o...

Embodiment 2

[0039] A kind of black tea processing technology, comprises the following steps:

[0040] (1), tea picking: pick 1 bud and 2 leaves on the tea tree, and fresh leaves free of diseases and insect pests are used for later use;

[0041] (2) Withering fermentation: put the fresh leaves picked in step (1) in the withering chamber of the body, the thickness of the spread tea is 14cm, put the withered black tea in the fermentation chamber of the body, the thickness of the spread tea is 18cm, start Frequency conversion motor, the power supply frequency of the frequency conversion motor is 60Hz, the speed of the frequency conversion motor is 1800r / min, the frequency conversion motor drives the rotating plate, the first fan and the second fan to rotate simultaneously through the rotating shaft, and the airflow generated when the second fan rotates enters through the through hole In the withering room, when the first fan rotates, a negative pressure will be formed at the center of rotatio...

Embodiment 3

[0047] A kind of black tea processing technology, comprises the following steps:

[0048] (1), tea picking: pick 1 bud and 2 leaves on the tea tree, and fresh leaves free of diseases and insect pests are used for later use;

[0049] (2), withering fermentation: put the fresh leaves picked in step (1) in the withering chamber of the body, the thickness of the tea spread is 15cm, put the withered black tea in the fermentation chamber of the body, the thickness of the tea spread is 20cm, start Frequency conversion motor, the power supply frequency of the frequency conversion motor is 100Hz, the speed of the frequency conversion motor is 3000r / min, the frequency conversion motor drives the rotating plate, the first fan and the second fan to rotate simultaneously through the rotating shaft, and the airflow generated by the rotation of the second fan enters through the through hole In the withering room, when the first fan rotates, a negative pressure will be formed at the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com