Red tea processing technology

A processing technology, black tea technology, applied in the direction of tea treatment before extraction, etc., can solve the problem that old leaves can only be processed separately, and achieve the effects of shortening picking time, reducing costs, and expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

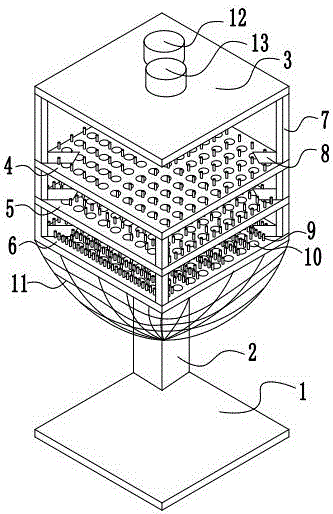

Image

Examples

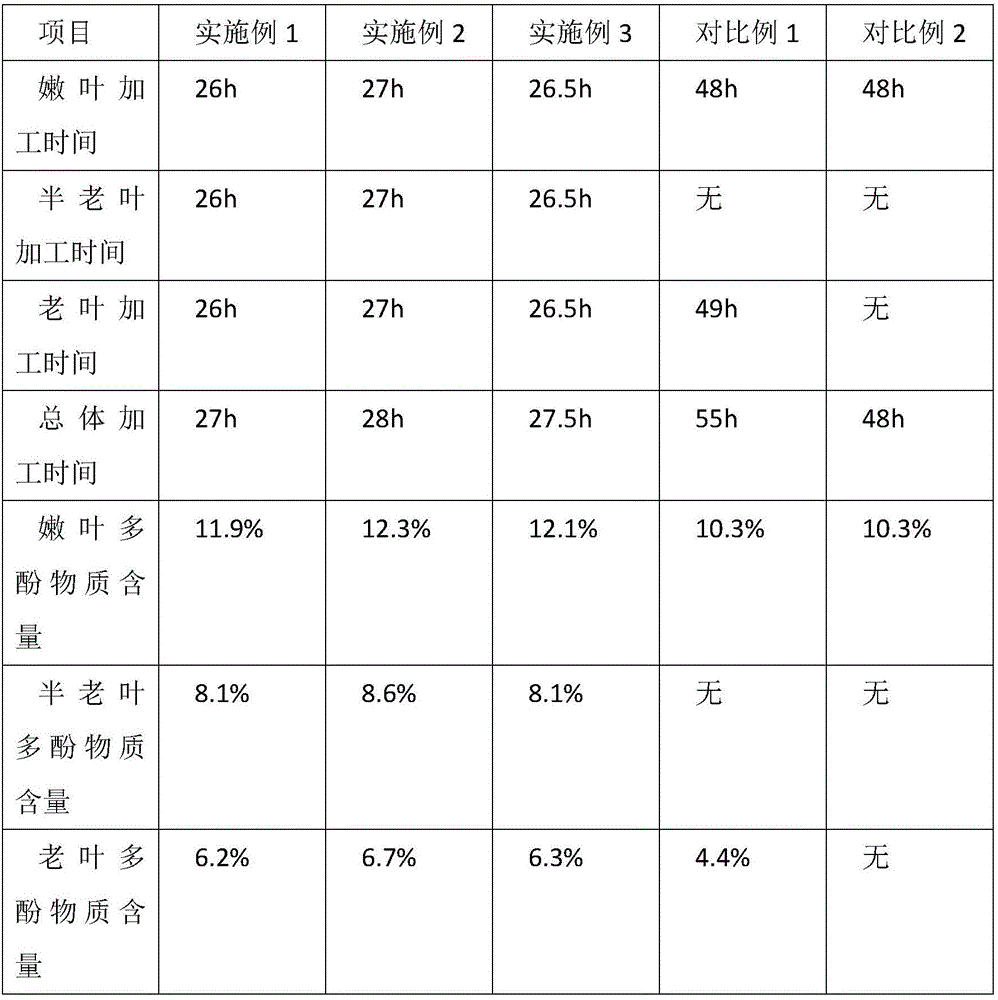

Embodiment 1

[0077] Example 1: In step 4, knead clockwise for 5 minutes, kneading pressure 3.3N, add tea ball weight 1% clarified lime water, heat up to 85°C, adjust water content to 40%; Machine greening for 4 seconds, spraying clarified lime water with 0.5% of the total weight of tea balls; in step 6, the rolling pressure is 2.1N, and spraying sodium bicarbonate solution is 1.3% of the total weight of tea balls; in step 7, the fermentation humidity is 55%, The temperature is 42°C, the last fermentation temperature is 60°C, and the fermentation time is 1 hour; in step 9, the step temperature difference is 3°C, and the tea leaves have a moisture content of 5% and stop drying; in step 10, sterilize for 2 seconds to make the tea leaves Moisture content is 2%.

Embodiment 2

[0078] Example 2: In step 4, knead clockwise for 5.5 minutes, kneading pressure 3.7N, add tea ball weight 2% clarified lime water, heat up to 90°C, adjust moisture content to 45%; in step 5, tea balls are placed in a 90°C Greening machine for 5 seconds, spraying clarified lime water with 0.9% of the total weight of tea balls; in step 6, rolling pressure is 2.2N, spraying sodium bicarbonate solution is 1.5% of the total weight of tea balls; in step 7, the fermentation humidity is 57% , the temperature is 44°C, the last fermentation temperature is 65°C, and the fermentation time is 1.5 hours; in step nine, the step temperature difference is 4°C, and the tea leaves have a moisture content of 5% to stop drying; in step ten, sterilize for 2 seconds, make The moisture content of tea leaves is 2%.

Embodiment 3

[0079] Example 3: In step 4, knead clockwise for 6 minutes, kneading pressure 4.2N, add tea ball weight 3% clarified lime water, heat up to 95°C, adjust moisture content to 50%; Machine greening for 6 seconds, spraying clarified lime water with 1.3% of the total weight of tea balls; in step 6, rolling pressure is 2.3N, spraying sodium bicarbonate solution is 1.7% of the total weight of tea balls; in step 7, the fermentation humidity is 60%, The temperature is 46°C, the last fermentation temperature is 70°C, and the fermentation time is 2 hours; in step 9, the step temperature difference is 6°C, and the tea leaves have a moisture content of 6% to stop drying; in step 10, sterilize for 3 seconds to make the tea leaves The moisture content is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com