Dendrocalamus latiflorus processing method

A processing method and technology for hemp bamboo shoots, applied in the field of processing hemp bamboo shoots, can solve the problems of single processing method and the inability of hemp bamboo shoot resources to get rid of poverty and become rich, and achieve the effects of storage resistance, enriching processing varieties, and alleviating labor pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

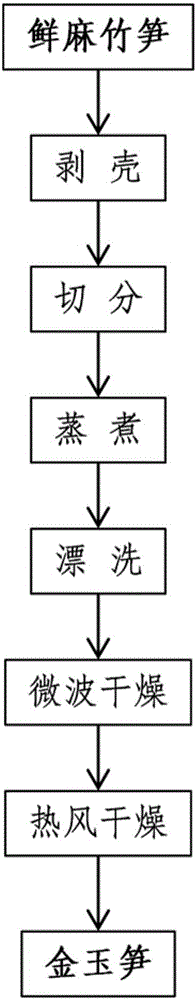

[0034] figure 1 It is a process flow diagram of a preferred embodiment of the bamboo shoot processing method of the present invention. Such as figure 1 Shown bamboo shoot processing method, it may further comprise the steps:

[0035] (1) Pretreatment: Peel the fresh bamboo shoots and cut them into flakes, cubes, strips or filaments. Specifically, select fresh bamboo shoots and shell them, and remove the inedible parts; use manual or machine to cut the shelled bamboo shoots into flakes and cubes with a length of 1 cm to 30 cm, a width of 0.5 cm to 12 cm, and a thickness of 0.5 cm to 1 cm. , strip or filament.

[0036] (2) Cooking: boil the pretreated bamboo shoots for 40 to 60 minutes in water at 100° C. to reduce the bitterness and astringency in the bamboo shoots.

[0037] (3) Rinse: Rinse the steamed bamboo shoots with clean water to remove the bitterness. Specifically, it can be washed twice with clean water to wash off the sediment of the bamboo shoots and the bamboo ...

Embodiment 2

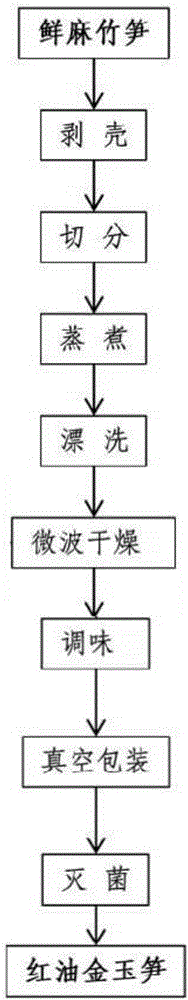

[0048] figure 2 It is a process flow diagram of another preferred embodiment of the bamboo shoot processing method of the present invention. Such as figure 2 Shown bamboo shoot processing method, it may further comprise the steps:

[0049] (1) Pretreatment: Peel the fresh bamboo shoots and cut them into flakes, cubes, strips or filaments. Specifically, select fresh bamboo shoots and shell them, and remove the inedible parts; use manual or machine to cut the shelled bamboo shoots into flakes and cubes with a length of 1 cm to 30 cm, a width of 0.5 cm to 12 cm, and a thickness of 0.5 cm to 1 cm. , strip or filament.

[0050] (2) Cooking: boil the pretreated bamboo shoots for 40 to 60 minutes in water at 100° C. to reduce the bitterness and astringency in the bamboo shoots.

[0051] (3) Rinse: Rinse the steamed bamboo shoots with clean water to remove the bitterness. Specifically, it can be washed twice with clean water to wash off the silt on the bamboo shoots and the bam...

Embodiment 3

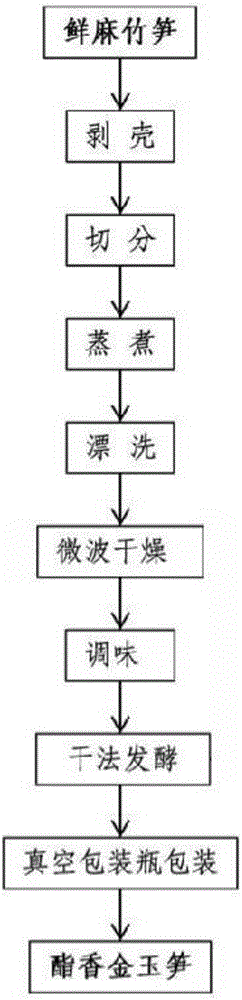

[0057] image 3 It is the process flow diagram of the third preferred embodiment of the bamboo shoot processing method of the present invention. Such as image 3 Shown bamboo shoot processing method, it may further comprise the steps:

[0058] (1) Pretreatment: Peel the fresh bamboo shoots and cut them into flakes, cubes, strips or filaments. Specifically, select fresh bamboo shoots and shell them, and remove the inedible parts; use manual or machine to cut the shelled bamboo shoots into flakes and cubes with a length of 1 cm to 30 cm, a width of 0.5 cm to 12 cm, and a thickness of 0.5 cm to 1 cm. , strip or filament.

[0059] (2) Cooking: boil the pretreated bamboo shoots for 40 to 60 minutes in water at 100° C. to reduce the bitterness and astringency in the bamboo shoots.

[0060] (3) Rinse: Rinse the steamed bamboo shoots with clean water to remove the bitterness. Specifically, it can be washed twice with clean water to wash off the silt on the bamboo shoots and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com