Preparation and application of ZIF-8@zinc phthalocyanine composite

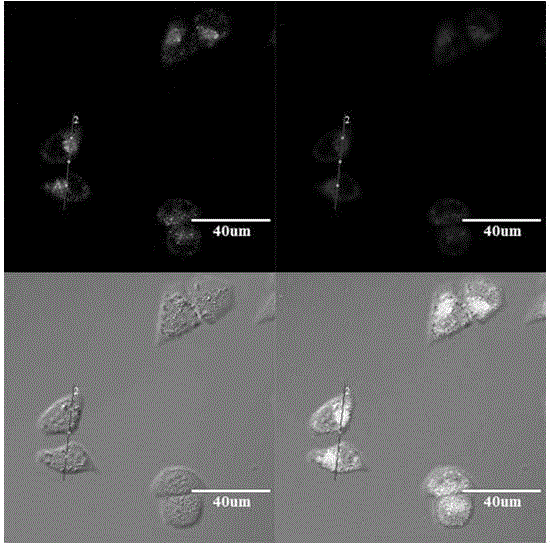

A composite material, the technology of ZIF-8, is applied in the directions of medical preparations without active ingredients, medical preparations containing active ingredients, and materials treated by wave energy or particle radiation, which can solve the problem of loss of photodynamic activity, phthalocyanine photodynamic Reduce the activity and other problems, to achieve the effect of superior photodynamic activity, uniform morphology, and broaden the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

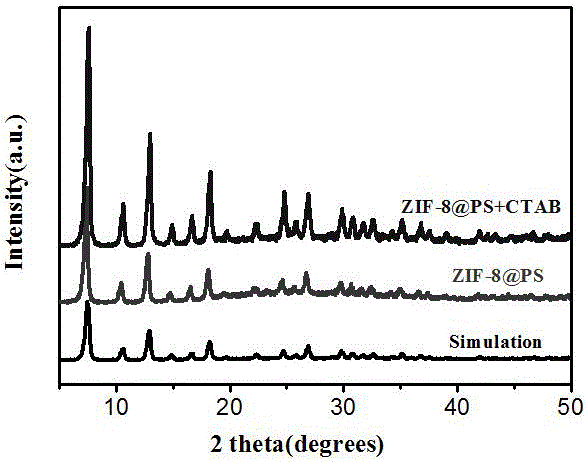

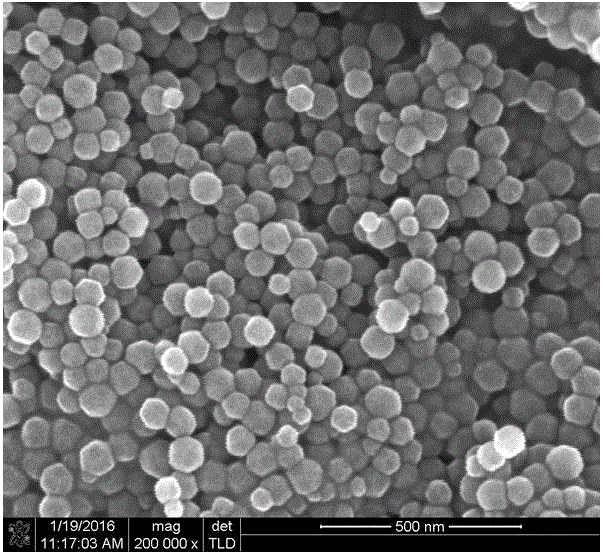

[0032] A preparation method of ZIF-8@phthalocyanine zinc composite material, the specific steps are:

[0033] 1) Preparation of ZIF-8@Zinc Phthalocyanine Composite Material: Weigh 150mg Zn(NO 3 ) 2 ·(H 2 O) 6 , dissolved in 7.5mL of methanol, 330mg of 2-methylimidazole was dissolved in 7.5mL of methanol, 10mg of zinc phthalocyanine (zinc phthalocyanine composite material) was dissolved in 1mL of N,N dimethylformamide, fully ultrasonicated Dissolve completely;

[0034] 2) Pour the above three fully dissolved solutions into a jar, then add 4mg of surfactant CTAB, and stir for 0.5h in one pot at room temperature;

[0035] 3) After the reaction is complete, collect the crude product by centrifugation at a centrifugation speed of 7000 rpm / min for 10 min; wash and purify the crude product with methanol, 15 mL each time, and wash three times;

[0036] 4) The obtained product was vacuum-dried in an oven at 60°C for 2 hours, and ground in an agate mortar to obtain the final produc...

Embodiment 2

[0038] A preparation method of ZIF-8@phthalocyanine zinc composite material, the specific steps are:

[0039] 1) Preparation of ZIF-8@Zinc Phthalocyanine Composite Material: Weigh 150mg Zn(NO 3 ) 2 ·(H 2 O) 6 , dissolved in 7.5mL of methanol, 330mg of 2-methylimidazole was dissolved in 7.5mL of methanol, 10mg of zinc phthalocyanine (zinc phthalocyanine composite material) was dissolved in 1mL of N,N dimethylformamide, fully ultrasonicated Dissolve completely;

[0040] 2) Pour the above three fully dissolved solutions into a jar, then add 4mg of surfactant CTAB, and stir for 0.25h in one pot at room temperature;

[0041] 3) After the reaction is complete, collect the crude product by centrifugation at a speed of 6000rpm / min for 15 minutes; wash and purify the crude product with methanol, 15 mL each time, and wash three times;

[0042] 4) The obtained product was vacuum-dried in an oven at 40°C for 3.5 hours, and ground in an agate mortar to obtain the final product.

Embodiment 3

[0044] A preparation method of ZIF-8@phthalocyanine zinc composite material, the specific steps are:

[0045] 1) Preparation of ZIF-8@Zinc Phthalocyanine Composite Material: Weigh 150mg Zn(NO 3 ) 2 ·(H 2 O) 6 , dissolved in 7.5mL of methanol, 330mg of 2-methylimidazole was dissolved in 7.5mL of methanol, 10mg of zinc phthalocyanine (zinc phthalocyanine composite material) was dissolved in 1mL of N,N dimethylformamide, fully ultrasonicated Dissolve completely;

[0046] 2) Pour the above three fully dissolved solutions into a jar, then add 4 mg of surfactant CTAB, and stir for 1 hour at room temperature;

[0047] 3) After the reaction is complete, collect the crude product by centrifugation at a centrifugation speed of 10,000 rpm / min for 8 min; wash and purify the crude product with methanol, 15 mL each time, and wash three times;

[0048] 4) The obtained product was vacuum-dried in an oven at 70°C for 2.5 hours, and ground in an agate mortar to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com