Oil shale mineral separation method

A beneficiation method and oil shale technology, applied in the oil shale industry, can solve the problems of lack of separation effect, unusable conventional jig coal separation technology, and ineffective separation of oil shale, etc. The effect of increasing resource utilization and reducing sorting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

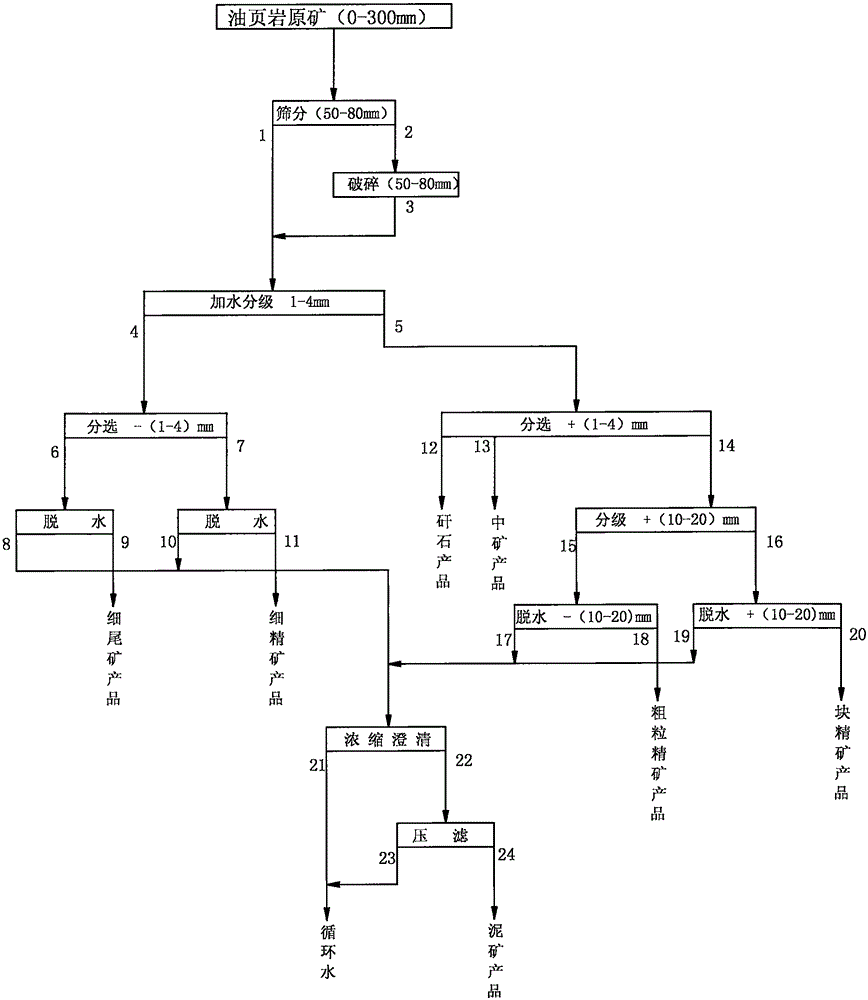

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as figure 1 Shown, a kind of oil shale beneficiation method technique of the present invention:

[0022] a. Sieve the oil shale raw ore with a particle size of (0-300mm) at 50-80mm to produce undersize 1 (+(50-80)mm) and oversize 2(-(50-80)mm) ;

[0023] b. Oversize 2 is crushed with a crusher until it is less than 50-80mm to become material 3, and mixed with undersize 1;

[0024] c. The mixed material is sprayed with water for 1-4mm classification, and two kinds of materials are produced after classification, fine-grained material 4 with a particle size of -(1-4)mm and coarse-grained material 5 with a particle size of +(1-4)mm ;

[0025] d. The fine-grained material 4 and water are sorted to produce heavy product 6 and light product 7. The heavy product 6 becomes fine-grained tailings product 9 after being dehydrated by the dewatering scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com