Ultrasonic spraying, cleaning, disinfecting and drying device

A spray cleaning and drying device technology, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of not meeting the market demand and upgrading the difficulty of cleaning, so as to shorten the heating time, reduce heat loss, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

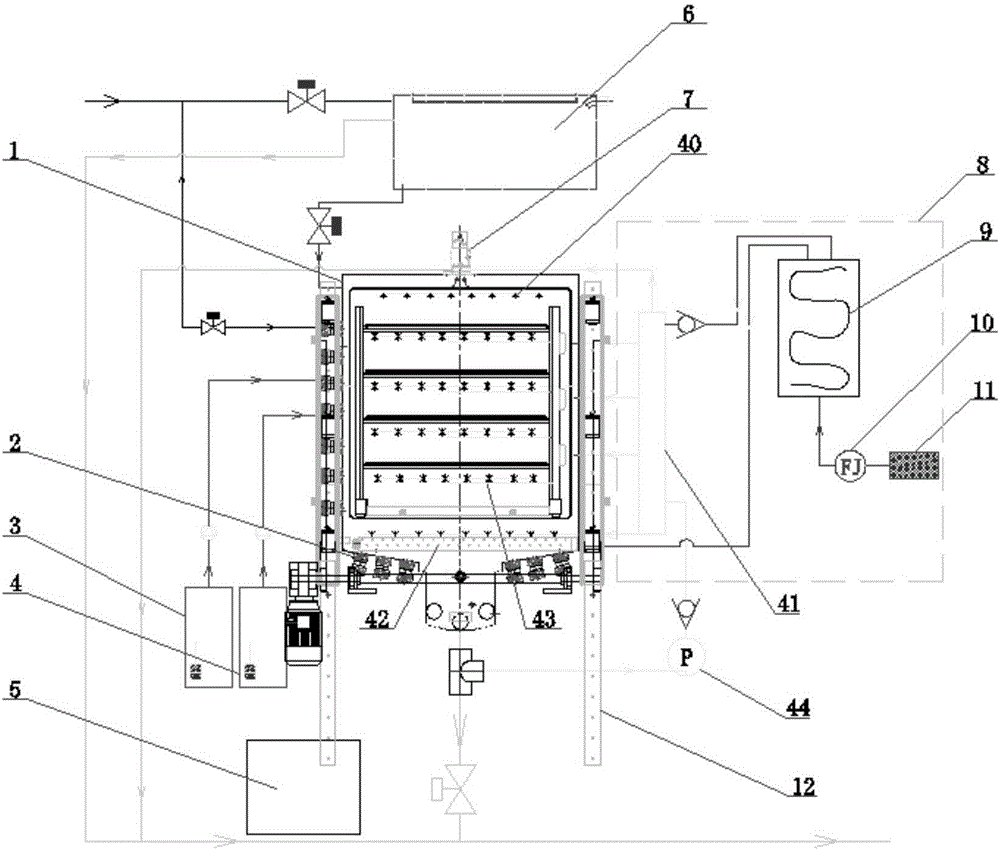

[0076] An ultrasonic spray cleaning, disinfection and drying device includes a cleaning tank 1, an ultrasonic transducer 2, an ultrasonic generator 5, a moisture removal device 7, a drying system 8, a heater 9, a high-pressure fan 10, a filter 11, and a movable door System 12 , spray arm rotation mechanism 40 , hot air and water distribution device 41 , hot air flow device 42 , cleaning frame 43 and water pump 44 .

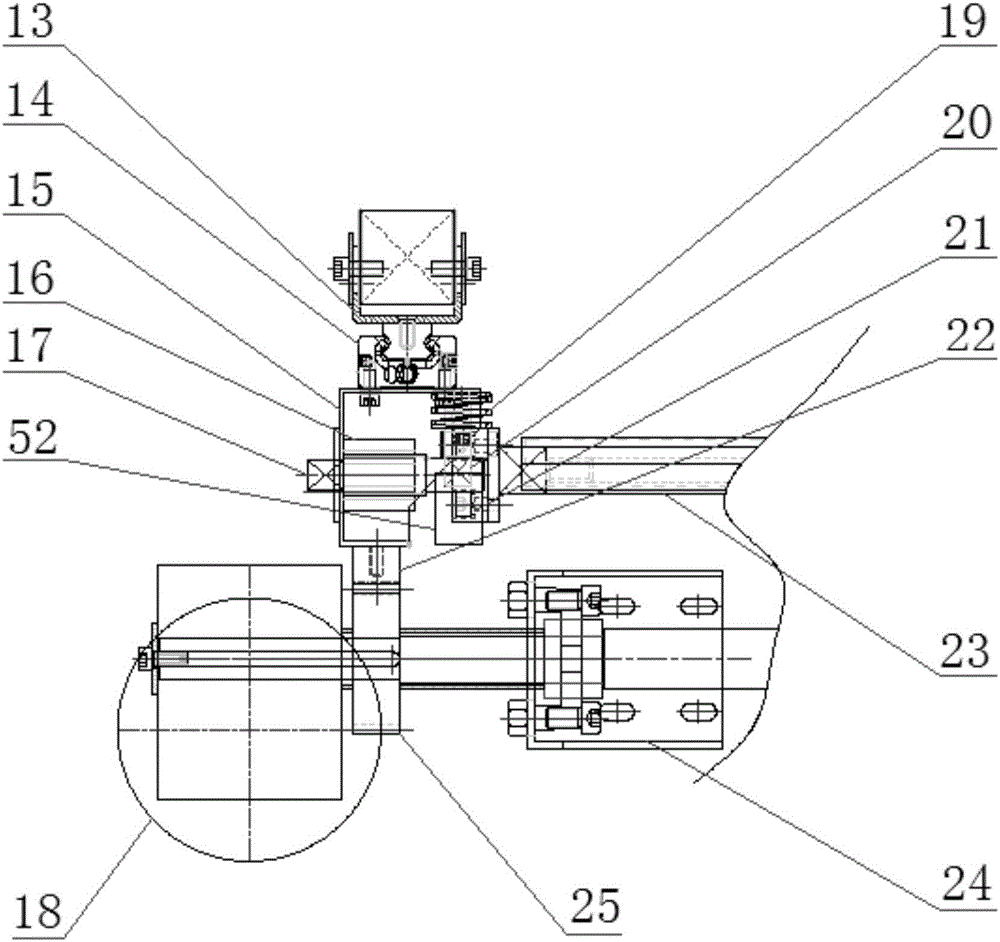

[0077] The movable door system 12 of the present invention is composed of guide rail seat 13, linear guide rail 14, rack fixed plate 15, door clamping shaft fixing seat 16, door clamping shaft 17, drive motor 18, compression spring 19, door guide wheel 20 , The door guide block 21, the transmission rack 22, the double-layer insulating glass sealed door 23, the transmission shaft support assembly 24, the transmission gear 25, and the door guide wheel guide rail 52 are composed.

[0078] The guide rail seat 13 of the movable door system of the present invention play...

Embodiment 2

[0095] The difference between Example 2 and Example 1 is that before starting Example 1, the hot water preheating system is turned on first. The present invention is provided with a preheating tank, which is made of high-quality 304 stainless steel, and the tank structure adopts double layers Insulation measures can effectively reduce heat loss, energy saving and environmental protection. The heating tube in the preheating tank adopts a new type of nano-heating tube, with a thermal efficiency of more than 95%, which greatly reduces the consumption of electric energy, and is energy-saving and environmentally friendly. The preheating tank has an independent water inlet mechanism, an overflow mechanism, a temperature control mechanism, a liquid level control mechanism, and a drainage mechanism connected with the main tank. The drain pipe of the preheating tank is connected to the top of the main tank through a control valve, and the connecting distance in the middle is shortened ...

Embodiment 3

[0097] The difference between embodiment 3 and embodiment 1 is that after cleaning with clean water, the metering pump 3 for cleaning enzyme and the metering pump 4 for lubricant can be started to add enzyme and lubricant to the object for cleaning, and the effect of repeated cleaning is better. like figure 1 As shown, after the cleaning and disinfection are completed, the instruments or workpieces still need to be dried, and the high-pressure hot air drying system 8 configured in the present invention solves this problem. The high-pressure hot air drying system 8 is a drying system that uses a combination of hot air and water splitter 41, a heater 9, a high-pressure fan 10, and a filter 11; the cold air enters the high-pressure fan 10 through the filter 11, and is sent to the heater by the high-pressure fan 10 9. The hot air heated by the heater 9 enters the hot air and water distribution device 41 all the way, and enters the cleaning tank 1 through the hot air and water dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com