Online restraining method for milling chatter

A milling chattering and chattering technology, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of affecting the machining accuracy of workpieces, unfavorable real-time transmission, and easy to cause coupling, etc., to achieve smooth and stable processing. The effect of high reliability and high acquisition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

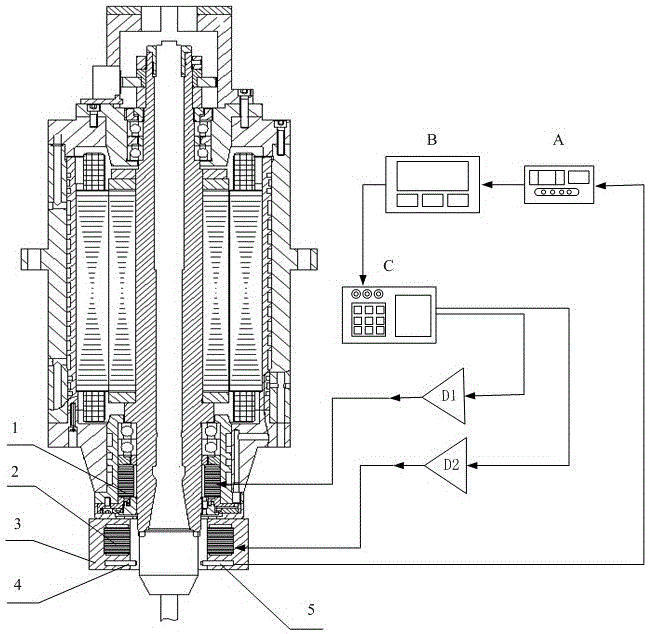

[0032] Such as figure 1 , 2 , 3, shown in 4, the steps of the present invention are as follows:

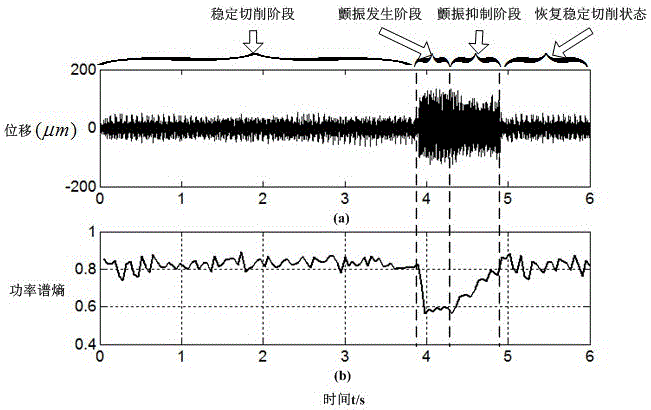

[0033] ① Use the data acquisition and processing module to collect the time-domain displacement signal of the processing process, calculate its power spectrum entropy value, and obtain the power spectrum entropy curve and frequency change characteristics;

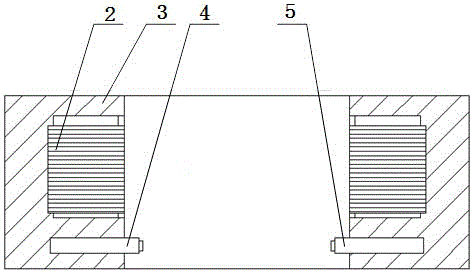

[0034] The data acquisition and processing module in 101 includes: a clamping disc 3 arranged at the lower end of the machine tool spindle, a first capacitive displacement sensor 4, a second capacitive displacement sensor 5, a collector and a data analyzer, the first capacitive displacement sensor The sensor 4 and the second capacitive displacement sensor 5 are symmetrically arranged at the lower end of the clamping disc 3, and are connected to a collector, and the collector is connected to a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com