A kind of preparation method of non-high temperature liquid phase growth graphene

A technology of graphene and liquid phase method is applied in the field of preparation of graphene grown by non-high temperature liquid phase method, which can solve the problems of high cost, low production efficiency and high processing cost, and achieve the effects of low pollution, low cost and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

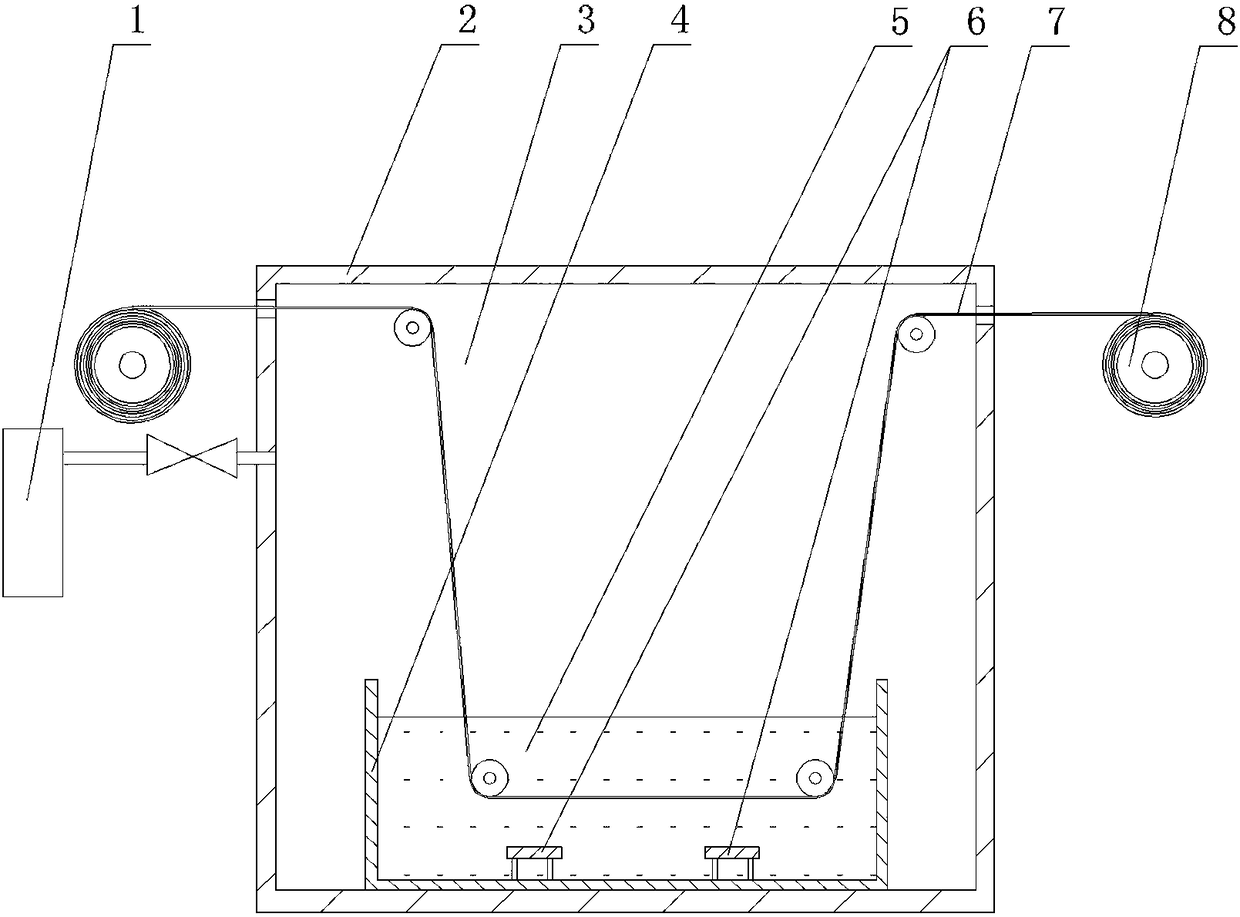

[0026] like figure 1 Shown, a kind of preparation method of non-high-temperature liquid-phase growth graphene of the present invention, its technical feature is that preparation method comprises the steps: a kind of preparation method of non-high-temperature liquid-phase growth graphene, its technical feature is that preparation method The method comprises the steps of: igniting the cold plasma 3 placed in the reaction chamber 2 in a protective gas, placing a container 4 of an organic solvent 5 working in a non-high temperature state in the plasma 3, and then introducing a gaseous carbon source 1 into the In the ignited cold plasma 3, the above-mentioned gaseous carbon source is activated and cracked or the liquid carbon source is evaporated and then activated and cracked, and the cracked carbon is fully dissolved in the above-mentioned organic solvent 5; the supercooled target film 7 is immersed in the The organic solvent 5 makes the carbon dissolved in the organic solvent 5 ...

Embodiment 2

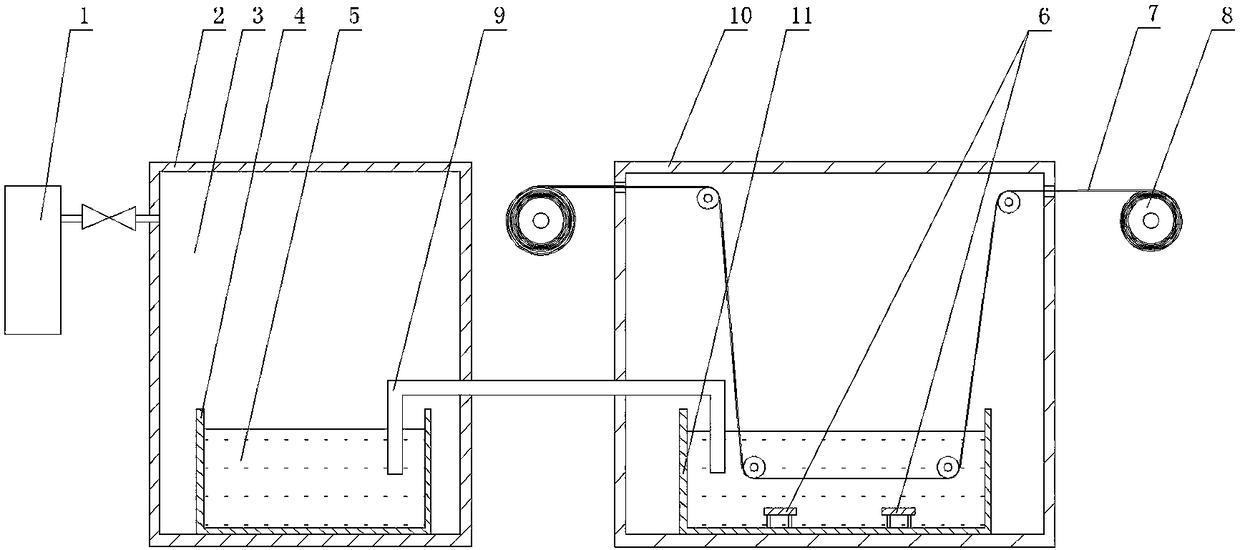

[0030] A method for preparing graphene grown by a non-high temperature liquid phase method of the present invention is characterized in that the preparation method includes the following steps: a method for preparing graphene grown by a non-high temperature liquid phase method is characterized in that the preparation method includes the following steps Ignite the cold plasma 3 placed in the reaction chamber 2 in the protective gas, place the container 4 of the organic solvent 5 working in a non-high temperature state in the plasma 3, then introduce the liquid carbon source 1 into the ignited cold In the plasma 3, the above-mentioned gaseous carbon source is activated and cracked or the liquid carbon source is evaporated and then activated and cracked, and the cracked carbon is fully dissolved in the above-mentioned organic solvent 5; the above-mentioned organic solvent 5 in which carbon has been dissolved is transported to another In the container 11 of a reaction chamber 10; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com