Water body heavy metal removal technique

A technology for heavy metals and water bodies, applied in the field of water treatment, can solve the problems of high preparation cost and limited application, and achieve the effects of good effect, environmentally friendly and renewable raw materials, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

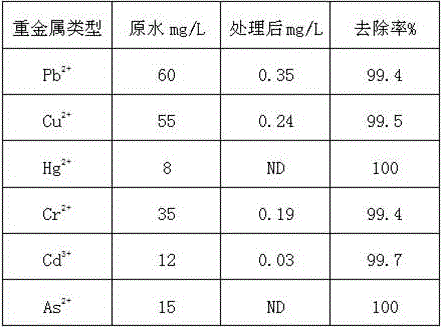

Image

Examples

Embodiment 1

[0028] A water heavy metal removal process, comprising the following steps:

[0029] A. Put the water body containing heavy metals into the reaction vessel, add chitosan, sodium alginate and aluminum hydroxide at a stirring speed of 120rpm; stir for 28min;

[0030] B. The solution is successively precipitated through the inclined tube sedimentation tank, and the bottom of the inclined tube is filled with fine sand;

[0031] C. Enter the flocculant into the static tube mixer, and the water in the static tube mixer is fully mixed with the flocculant;

[0032] D. The water mixed with flocculant enters No. 1 filter;

[0033] E. The effluent from No. 1 filter enters the storage tank, and its heavy metal content is tested. If the heavy metal content meets the drainage requirements, it will flow directly into the clear water tank; if the heavy metal content does not meet the drainage requirements, the water will pass through the static water again. Tubular mixer and add flocculant,...

Embodiment 2

[0045] A water heavy metal removal process, comprising the following steps:

[0046] A. Put the water body containing heavy metals into the reaction vessel, add chitosan, sodium alginate and aluminum hydroxide at a stirring speed of 120rpm; stir for 30min;

[0047] B. The solution is successively precipitated through the inclined tube sedimentation tank, and the bottom of the inclined tube is filled with fine sand;

[0048] C. Enter the flocculant into the static tube mixer, and the water in the static tube mixer is fully mixed with the flocculant;

[0049] D. The water mixed with flocculant enters No. 1 filter;

[0050] E. The effluent from No. 1 filter enters the storage tank, and its heavy metal content is tested. If the heavy metal content meets the drainage requirements, it will flow directly into the clear water tank; if the heavy metal content does not meet the drainage requirements, the water will pass through the static water again. Tubular mixer and add flocculant,...

Embodiment 3

[0062] A water heavy metal removal process, comprising the following steps:

[0063] A. Put the water body containing heavy metals into the reaction vessel, add chitosan, sodium alginate and aluminum hydroxide at a stirring speed of 120rpm; stir for 25-30min;

[0064] B. The solution is successively precipitated through the inclined tube sedimentation tank, and the bottom of the inclined tube is filled with fine sand;

[0065] C. Enter the flocculant into the static tube mixer, and the water in the static tube mixer is fully mixed with the flocculant;

[0066] D. The water mixed with flocculant enters No. 1 filter;

[0067] E. The effluent from No. 1 filter enters the storage tank, and its heavy metal content is tested. If the heavy metal content meets the drainage requirements, it will flow directly into the clear water tank; if the heavy metal content does not meet the drainage requirements, the water will pass through the static water again. Tubular mixer and add floccula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com