Method and device for treating organic pollutant in water of tetramino iron ligand catalyst-strong alkali resin compound system

A technology for compounding organic pollutants and resins, applied in water pollutants, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc. Achieve good economic and environmental benefits, efficient removal, and low input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

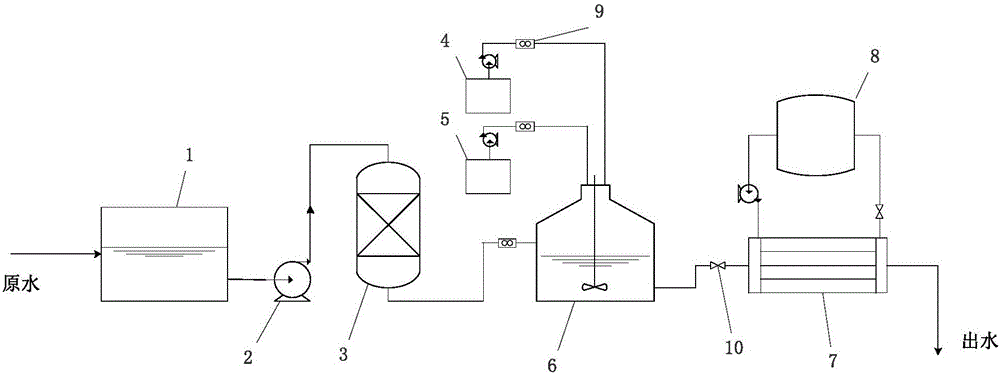

Method used

Image

Examples

Embodiment 1

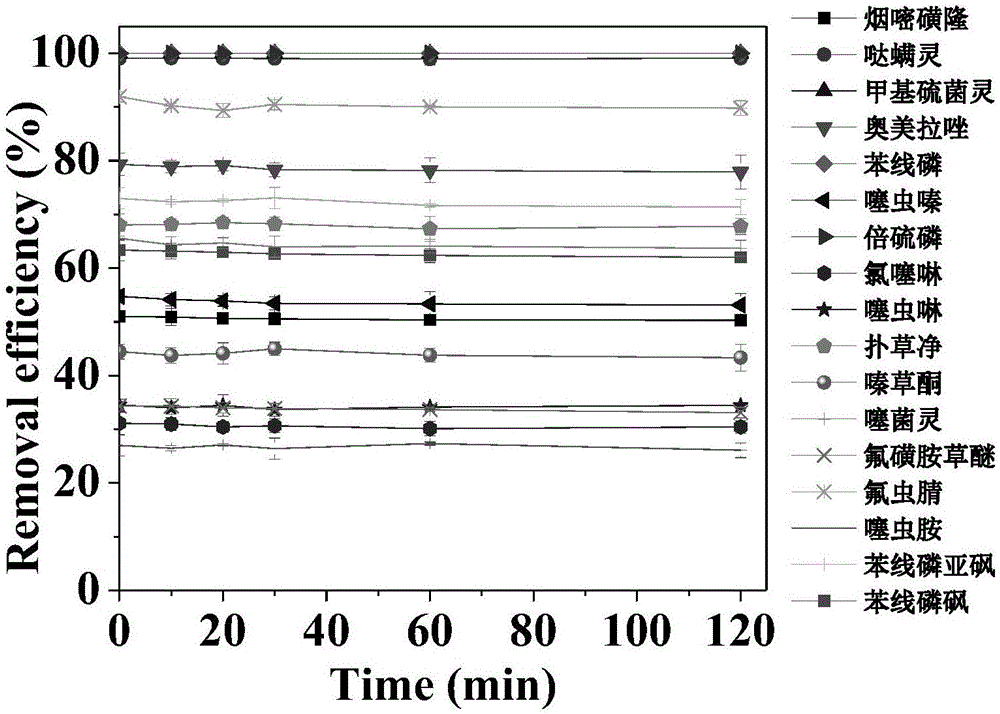

[0025] Prepare an aqueous solution of an organic pollutant mixed standard with a concentration of 50 μg / L, adjust the pH to 7, add it to the mixing tank, and add ethyl-substituted tetraaminoiron ligand catalyst and hydrogen peroxide so that the concentrations are 1 μg / L and 10 mmol / L respectively After mixing, enter the activated D201 basic resin column, and take samples from 0, 10, 20, 30, 60, 120 minutes after the solution drips from the resin column, and analyze the samples by HPLC-MS / MS. The composite system has a removal rate of 26-99% for sulfur-containing pollutants, and after 2 hours of treatment, the catalytic activity has not decreased, and the pH value of the effluent is 7.8, only changing 0.8 (see figure 2 ).

Embodiment 2

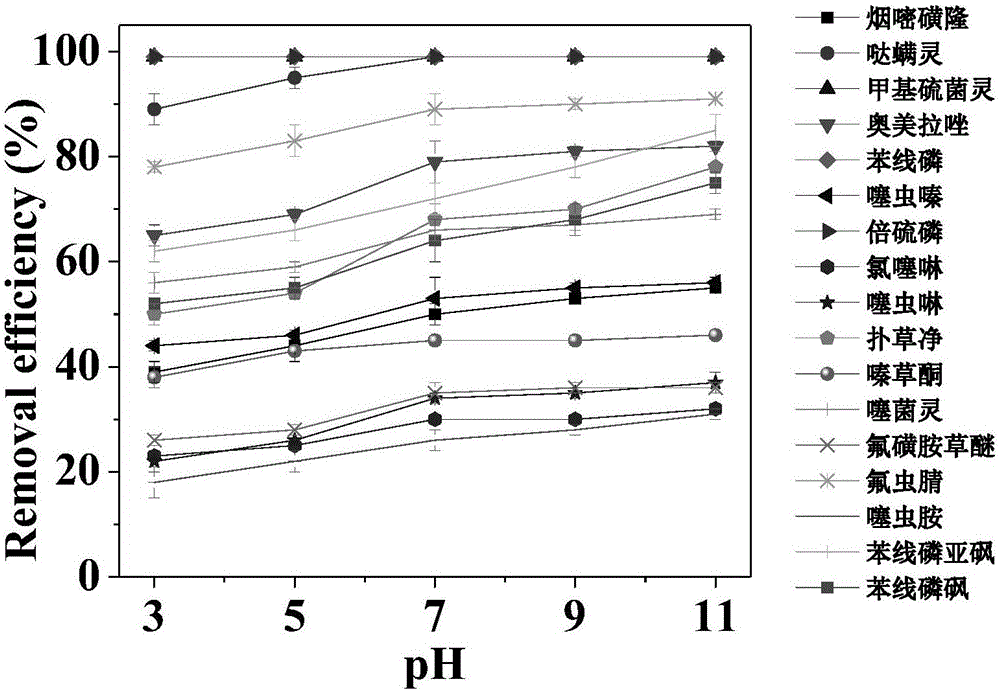

[0027] Prepare an aqueous solution of organic pollutants with a concentration of 50 μg / L, and adjust the pH to 3, 5, 7, 9, and 11 respectively to investigate the effect of the raw water pH on the composite system. Bulk catalyst and hydrogen peroxide so that the concentrations are 1μg / L and 10mmol / L, respectively, after mixing, enter the activated D201 basic resin column for processing. After 2 hours of treatment, the composite system can remove 18-99% of organic pollutants under the condition of pH 3, and the pH value of the effluent is 4.2, which only changes by 1.2; the composite system can remove sulfur-containing pollutants under the condition of pH 5 The removal rate of sulfur-containing pollutants reached 26-99%, and the pH value of the effluent was 7.8, which only changed by 0.8; The composite system has a removal rate of 28-99% for sulfur-containing pollutants under the condition of pH 9, and the pH of the effluent is 9.4, which only changes by 0.4; the removal rate of...

Embodiment 3

[0029] Configure 5mg / L bisphenol A solution, add it to the mixing tank, add dissolved organic matter (DOM) to investigate its influence on the composite system, the DOM concentration is 10mg / L, add ethyl-substituted tetraaminoiron ligand catalyst and peroxide Hydrogen makes the concentrations of 10μg / L and 100mmol / L respectively, mixes and enters the activated D201 basic resin column, and takes samples for analysis 120min after the solution starts to drip out from the resin column. After 2 hours of treatment, the degradation rate of bisphenol A still reached over 98%, and DOM had no effect on the composite system for treating organic pollutants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com