Method for preparing hemodialysis membrane containing bamboo shoot fibers

A bamboo shoot fiber, hemodialysis technology, applied in dialysis systems, wet spinning and other directions, can solve the problems of macromolecular permeability effect, negative effect on dialysis performance, etc., achieve excellent biocompatibility, improve hemodialysis performance, overcome Effects of adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

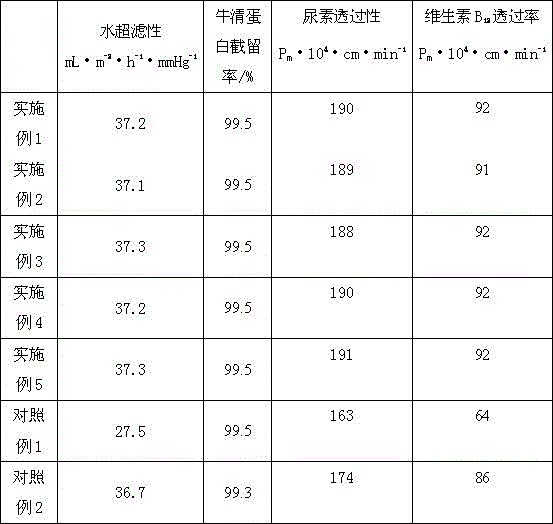

Examples

Embodiment 1

[0024] A preparation method for a hemodialysis membrane containing bamboo shoot fiber, comprising the steps of:

[0025] Step 1, preparation of bamboo shoot fiber powder: After cleaning and slicing bamboo shoot raw materials, perform grinding treatment, then rinse with water, put into dilute hydrochloric acid solution for acid treatment, the pH of acid treatment is 3, and the treatment time is 3h; rinse with water until After the pH is 7, put it into NaOH solution for alkali treatment, the pH of the alkali treatment is 12, and the treatment time is 2 hours. After the alkali treatment, wash with boiling water until neutral, then dry and pulverize, and pass through a 150-mesh sieve to obtain Bamboo shoot fiber powder;

[0026] In the second step, 30Kg of cellulose acetate and 25Kg of polyacrylonitrile are added to 40Kg of acetone and DMAC mixed solvent, wherein 20Kg of acetone and 20Kg of DMAC; mix well to obtain the initial mixture;

[0027] The 3rd step, add bamboo shoot fibe...

Embodiment 2

[0032] A preparation method for a hemodialysis membrane containing bamboo shoot fiber, comprising the steps of:

[0033] Step 1, preparation of bamboo shoot fiber powder: After cleaning and slicing bamboo shoot raw materials, perform grinding treatment, then rinse with water, put into dilute hydrochloric acid solution for acid treatment, the pH of acid treatment is 3, and the treatment time is 3h; rinse with water until After the pH is 7, put it into NaOH solution for alkali treatment, the pH of the alkali treatment is 12, and the treatment time is 2 hours. After the alkali treatment, wash with boiling water until neutral, then dry and pulverize, and pass through a 150-mesh sieve to obtain Bamboo shoot fiber powder;

[0034] In the second step, 45Kg of cellulose acetate and 35Kg of polyacrylonitrile are added to 75Kg of acetone and DMAC mixed solvent, wherein 25Kg of acetone and 50Kg of DMAC; mix well to obtain the initial mixture;

[0035] The 3rd step, add bamboo shoot fibe...

Embodiment 3

[0040] A preparation method for a hemodialysis membrane containing bamboo shoot fiber, comprising the steps of:

[0041] Step 1, preparation of bamboo shoot fiber powder: After cleaning and slicing bamboo shoot raw materials, perform grinding treatment, then rinse with water, put into dilute hydrochloric acid solution for acid treatment, the pH of acid treatment is 3, and the treatment time is 3h; rinse with water until After the pH is 7, put it into NaOH solution for alkali treatment, the pH of the alkali treatment is 12, and the treatment time is 2 hours. After the alkali treatment, wash with boiling water until neutral, then dry and pulverize, and pass through a 150-mesh sieve to obtain Bamboo shoot fiber powder;

[0042]In the second step, 35Kg of cellulose acetate and 28Kg of polyacrylonitrile are added to 45Kg of acetone and DMAC mixed solvent, wherein 15Kg of acetone and 30Kg of DMAC; mix well to obtain the initial mixture;

[0043] In the 3rd step, add bamboo shoot fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com