Preparation method of hydrophobic micro-nano structure aluminum surface

A technology of micro-nano structure and aluminum surface, which is applied in the fields of nanotechnology, nanotechnology and nanotechnology for materials and surface science, can solve the problems of high cost and complicated preparation scheme, achieve simple use, improve hydrophobic performance, Deploy simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Sand the aluminum base with a size of 20*20*2mm with sandpaper, ultrasonically clean it with acetone and distilled water, and dry it in a drying oven to remove the oil and oxide layer on the surface;

[0024] Chemical etching: put the pretreated aluminum substrate into the etching solution, prepare a hydrochloric acid solution, place the aluminum substrate in the solution for etching for 14 hours at room temperature, then ultrasonically clean with anhydrous ethanol and distilled water, and then dry in a drying oven ; Then placed in the configured cupric chloride solution to etch the surface for 3 minutes, followed by ultrasonic cleaning with absolute ethanol and distilled water and drying with a drying oven. Described hydrochloric acid solution concentration is 0.8mol / L, and described cupric chloride solution concentration is 0.8mol / L;

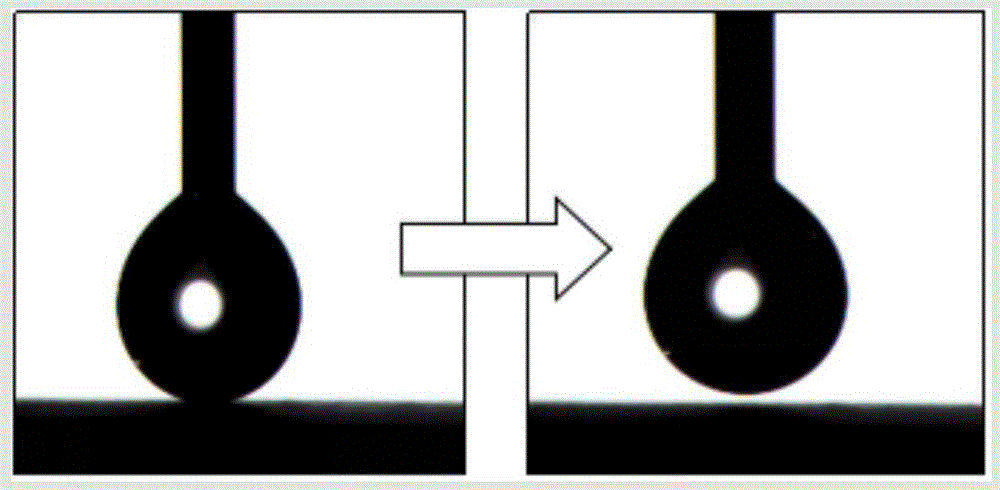

[0025] Surface modification: Put the etched aluminum base into the prepared 0.2mol / L stearic acid absolute ethanol solution, modify th...

Embodiment 2

[0027] Sand the aluminum base with a size of 20*20*2mm with sandpaper, ultrasonically clean it with acetone and distilled water, and dry it in a drying oven to remove the oil and oxide layer on the surface;

[0028] Chemical etching: put the pretreated aluminum base into the etching solution, prepare a hydrochloric acid solution, place the aluminum base in the solution for etching for 11 hours at room temperature, then ultrasonically clean with anhydrous ethanol and distilled water, and then dry in a drying oven ; Then placed in the configured cupric chloride solution to etch the surface for 3 minutes, followed by ultrasonic cleaning with absolute ethanol and distilled water and drying with a drying oven. Described hydrochloric acid solution concentration is 0.8mol / L, and described cupric chloride solution concentration is 0.8mol / L;

[0029] Surface modification: Put the etched aluminum base into the prepared 0.1mol / L stearic acid absolute ethanol solution, modify the aluminum...

Embodiment 3

[0031] Sand the aluminum base with a size of 20*20*2mm with sandpaper, ultrasonically clean it with acetone and distilled water, and dry it in a drying oven to remove the oil and oxide layer on the surface;

[0032] Chemical etching: Put the pretreated aluminum base into the etching solution, prepare a hydrochloric acid solution, place the aluminum base in the solution for etching for 8 hours at room temperature, then ultrasonically clean with anhydrous ethanol and distilled water, and then dry in a drying oven ; Then placed in the configured cupric chloride solution to etch the surface for 3 minutes, followed by ultrasonic cleaning with absolute ethanol and distilled water and drying with a drying oven. Described hydrochloric acid solution concentration is 0.8mol / L, and described cupric chloride solution concentration is 0.8mol / L;

[0033] Surface modification: Put the etched aluminum base into the prepared 0.1mol / L stearic acid absolute ethanol solution, modify the aluminum ...

PUM

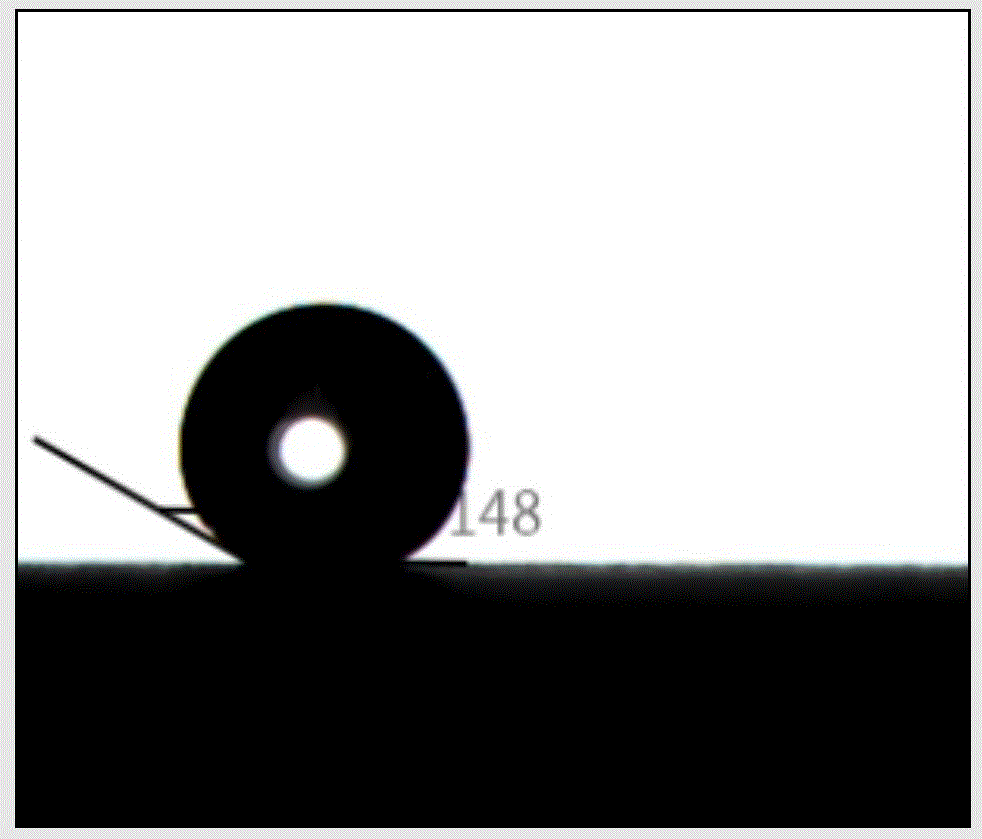

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com