Composite surface drug-carrying slow-release system and preparation method thereof

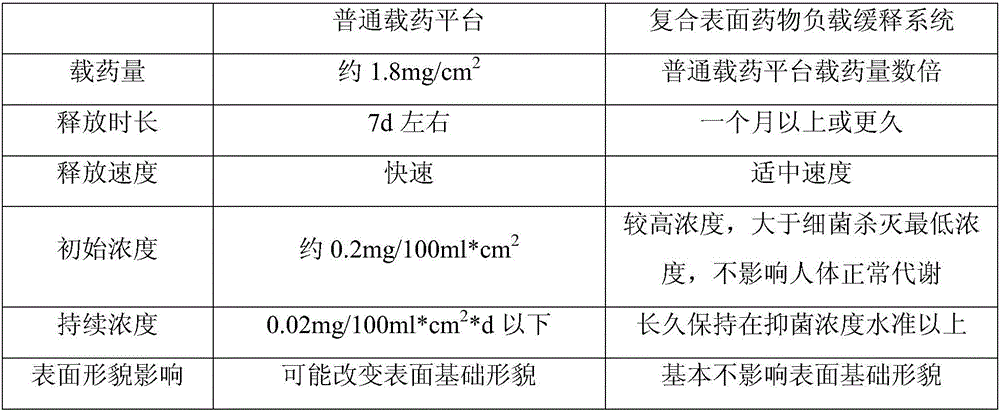

A composite surface and drug technology, which is applied in the direction of pharmaceutical formulation, drug delivery, surface reaction electrolytic coating, etc., can solve the problems of unstable implantation of titanium nails, inability to meet sterilization, loosening, etc., and achieve the effect of increasing drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] An embodiment of the compound surface drug-loaded slow-release system and its preparation method of the present invention. Wherein, the preparation method of the composite surface drug-loaded slow-release system comprises the following steps:

[0043] (1) Surface pretreatment

[0044] Select a commercial four-grade pure titanium sheet with a length, width and thickness of 10mm, 10mm and 1.5mm, respectively, and polish it externally; then immerse it in a mixed solution of acetone and ethanol and wash it ultrasonically for 10 minutes to remove organic dirt on the surface of the drug-loaded substrate. Then in NaF:HNO 3 :H 2 Soak in a weakly acidic solution with a mass ratio of 2:18:80 for 1 min to remove the natural oxide film on the surface of the drug-loaded substrate, and then ultrasonically clean it with ultrapure water for 10 min.

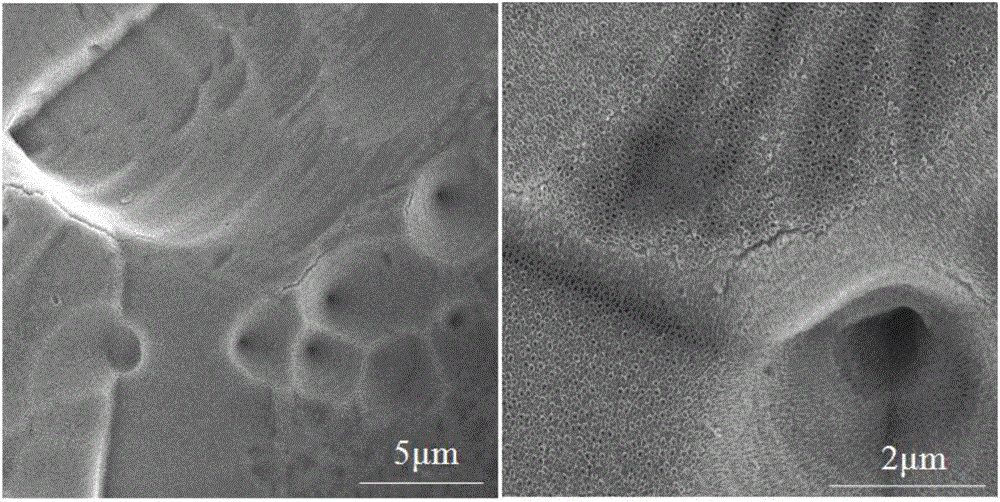

[0045] (2) Micro-hole structure formation

[0046] The drug-loaded substrate after surface pretreatment was immersed in an alkaline s...

Embodiment 2

[0056] An embodiment of the compound surface drug-loaded slow-release system and its preparation method of the present invention. Wherein, the preparation method of the composite surface drug-loaded slow-release system comprises the following steps:

[0057] (1) Surface pretreatment

[0058] Select a commercial four-grade pure titanium sheet with a length, width and thickness of 10mm, 10mm and 1.5mm, respectively, and polish it externally; then immerse it in a mixed solution of acetone and ethanol and wash it ultrasonically for 10 minutes to remove organic dirt on the surface of the drug-loaded substrate. Then in NaF:HNO 3 :H 2 Soak in a weakly acidic solution with a mass ratio of 2:18:80 for 1 min to remove the natural oxide film on the surface of the drug-loaded substrate, and then ultrasonically clean it with ultrapure water for 10 min.

[0059] (2) Micro-hole structure formation

[0060] The drug-loaded substrate after surface pretreatment was immersed in an alkaline s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com