Lightweight insulation waterproof board and production technology

A production process and waterproof board technology, applied in the direction of layered products, synthetic resin layered products, glass/slag layered products, etc., can solve the problems that restrict the development of high-quality decoration, easy leakage and cracking of decorative materials, and achieve Conducive to environmental maintenance, convenient and efficient installation, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

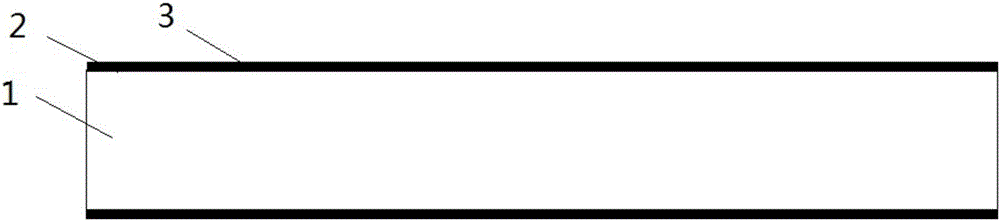

[0028] First of all: the plate structure is a composite three-layer structure: the middle is the XPS extruded plate 1 divided according to the product thickness requirements, the upper and lower sides of the XPS plate are covered with glass fiber mesh 2, and the prepared modified cement mortar 3 is evenly coated on the The surface of the extruded board and make it firmly bonded; the cement-based component made of the XPS extruded board foam board as the base material is to engrave or process the extruded board and then arrange the glass fiber mesh on its surface and use modified cement mortar Apply evenly on the surface of extruded board, and make the glass fiber mesh and XPS extruded board firmly bonded. This is the structure of the light weight, thermal insulation, waterproof, anti-fire, anti-corrosion board or component.

[0029] Secondly: in terms of material selection: the XPS extruded board of the middle layer is a kind of high compressive strength (≥kpa700), the foam po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com