Preparation method of hierarchical porous titanium silicalite molecular sieves

A titanium-silicon molecular sieve and channel technology, applied in molecular sieve compounds, molecular sieve catalysts, molecular sieve characteristic silicates, etc., can solve the problems of PVA being unable to play a template role, phase separation, weakening of the precursor solution, etc., and achieve excellent catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

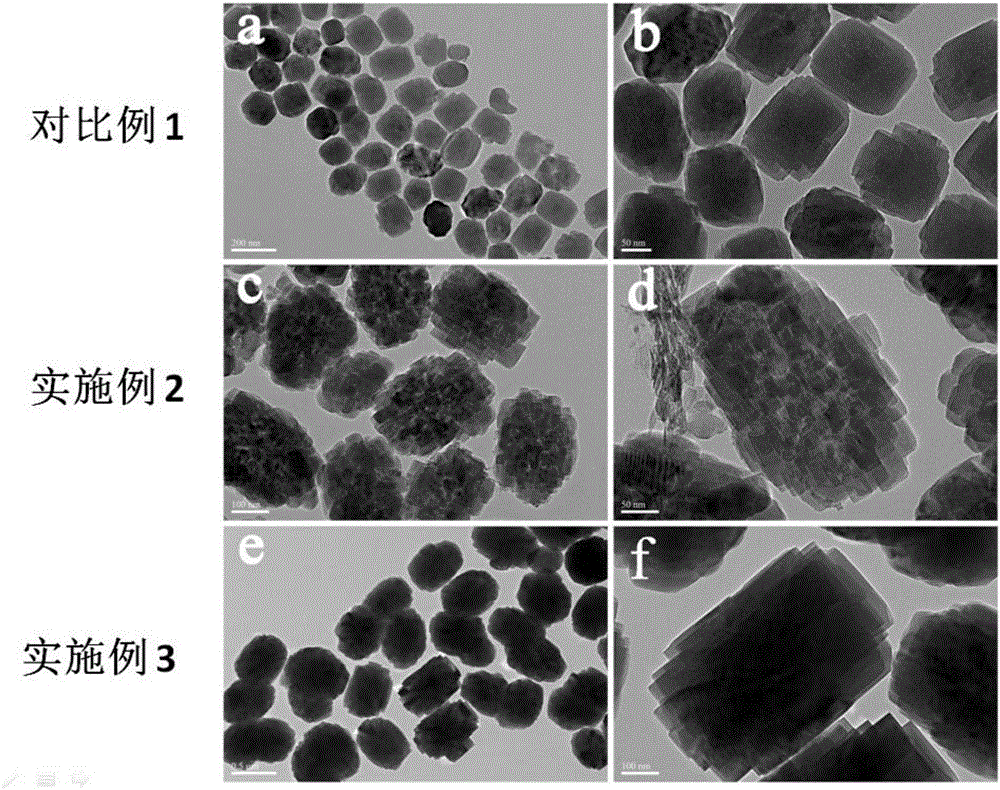

Embodiment 1

[0030] Under the condition of continuous stirring, 23.4g tetrapropylammonium hydroxide (20wt%) was slowly added in 15.0g tetraethyl orthosilicate, after tetraethyl orthosilicate was completely hydrolyzed, a colorless and transparent solution A was obtained; then , the mixed solution B of 0.72g titanium source and 2.4g isopropanol is slowly added in solution A to obtain colorless and transparent solution C; ) after being fully mixed, the solution was transferred to a hydrothermal reaction kettle, first crystallized at 90° C. for 24 hours, and then heated to 160° C. for 24 hours. After the obtained product was centrifuged and washed, it was dried at 110°C overnight, and finally the obtained solid was calcined at 550°C for 6 hours to finally obtain the multi-level channel TS-1.

Embodiment 2

[0032] Under the condition of continuous stirring, 23.4g tetrapropylammonium hydroxide (20wt%) was slowly added in 15.0g tetraethyl orthosilicate, after tetraethyl orthosilicate was completely hydrolyzed, a colorless and transparent solution A was obtained; then , the mixed solution B of 0.72g titanium source and 2.4g isopropanol was slowly added to solution A to obtain a colorless and transparent solution C; after solution C was removed from alcohol at 80°C for 2h, it was mixed with PVA solution of the same quality (10.0wt%) ) after being fully mixed, the solution was transferred to a hydrothermal reaction kettle, first crystallized at 90° C. for 24 hours, and then heated to 160° C. for 24 hours. After the obtained product was centrifuged and washed, it was dried at 110°C overnight, and finally the obtained solid was calcined at 550°C for 6 hours to finally obtain the multi-level channel TS-1.

Embodiment 3

[0034] Under the condition of continuous stirring, 23.4g tetrapropylammonium hydroxide (20wt%) was slowly added in 15.0g tetraethyl orthosilicate, after tetraethyl orthosilicate was completely hydrolyzed, a colorless and transparent solution A was obtained; then , the mixed solution B of 0.72g titanium source and 2.4g isopropanol was slowly added to solution A to obtain a colorless and transparent solution C; after solution C was removed from alcohol at 80°C for 2h, it was mixed with PVA solution of the same quality (15.0wt%) ) after being fully mixed, the solution was transferred to a hydrothermal reaction kettle, first crystallized at 90° C. for 24 hours, and then heated to 160° C. for 24 hours. After the obtained product was centrifuged and washed, it was dried at 110°C overnight, and finally the obtained solid was calcined at 550°C for 6 hours to finally obtain the multi-level channel TS-1.

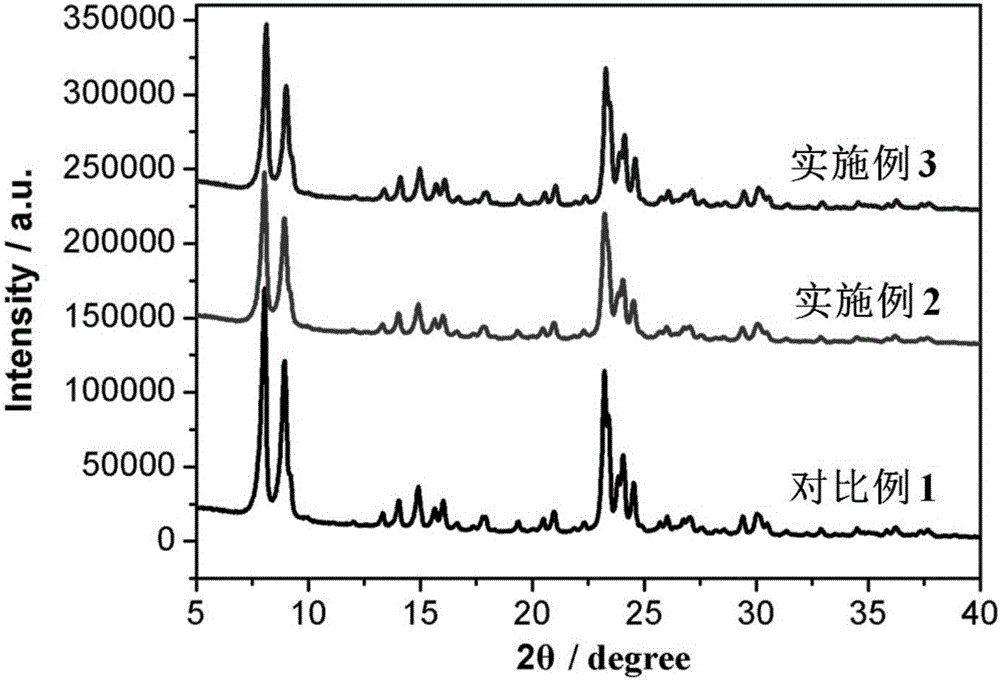

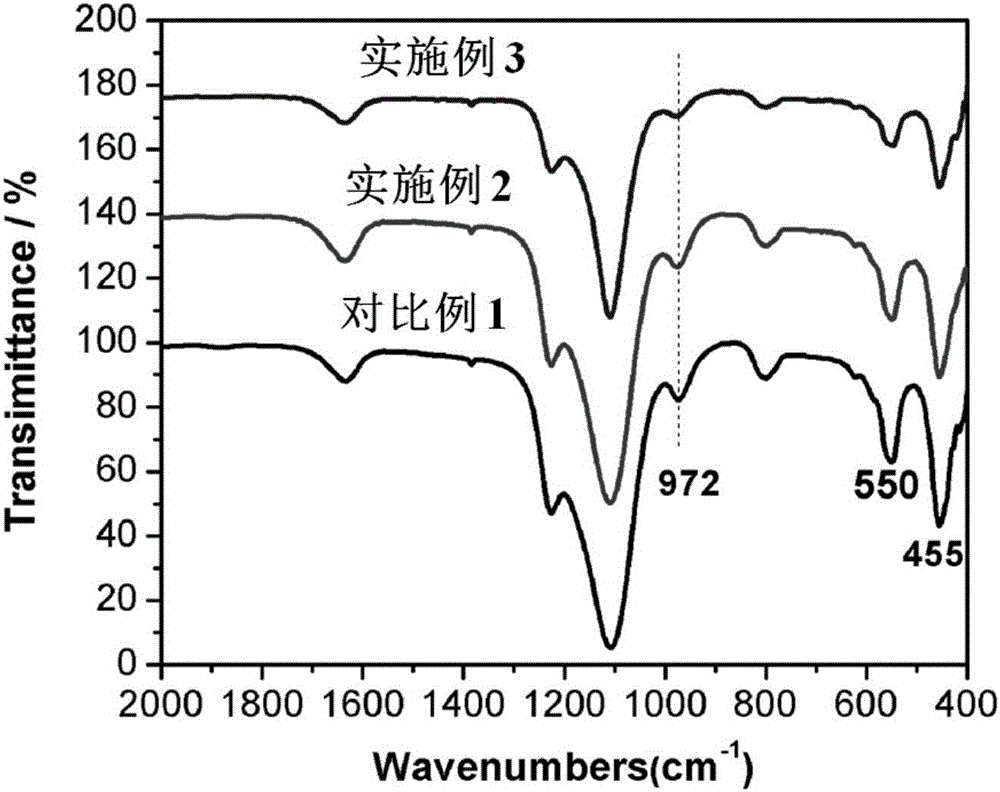

[0035] figure 1 It is the XRD spectrum of the titanium-silicon molecular sieve T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com