Renewable adsorbent for hydrogen sulfide removal and preparation method thereof

An adsorbent and hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of cumbersome preparation process and high manufacturing cost of adsorbents, achieve concentration of mesoporous channels, improve utilization effect, and save The effect of operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

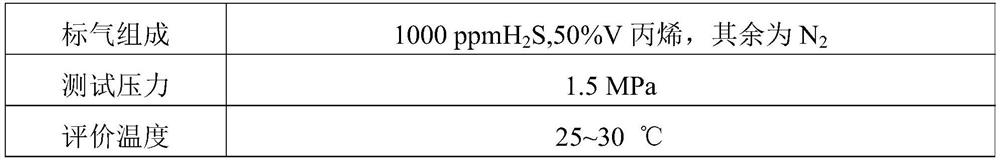

[0044] Step 1: Weigh 100g of activated alumina and 100g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 15, add it to 375g of sodium metaaluminate solution with a concentration of 2.8%wt, and maintain at 80°C for 4h under stirring conditions.

[0045] Step 2: drying the slurry solution obtained in Step 1 at a temperature of 100° C. for 8 hours, and then crushing and grinding to obtain a modified mixed powder.

[0046] Step 3, mix 150g of mixed powder obtained in step 2 with 80g of sodium acetate and sodium bicarbonate with a concentration of 0.5%wt, wherein the mass ratio of sodium acetate to sodium bicarbonate is 1:1, mix and shape to obtain spherical particles, and then Drying at 100°C, followed by calcination at 200°C for 1 hour, 450°C for 0.5 hours, and 550°C for 0.5 hours to obtain the finished adsorbent. Labeled as sample S-1.

Embodiment 2

[0048] Step 1: Weigh 100g of activated alumina and 20g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 150, add it to 360g of 5%wt sodium metaaluminate solution, and maintain at 80°C for 4h under stirring conditions.

[0049] Step 2: Spray-dry the slurry solution obtained in Step 1 at a temperature of 180° C. for 0.5 h to obtain a modified mixed powder.

[0050] Step 3, mix 130g of the mixed powder obtained in step 2 with 100g, the concentration is 3.0%wt sodium acetate and sodium bicarbonate, wherein the mass ratio of sodium acetate and sodium bicarbonate is 1:1, mix and shape to obtain bar-shaped particles, and then Drying at 100°C, followed by calcination at 200°C for 1h, 450°C for 0.5h, and 550°C for 0.5h to obtain the finished adsorbent. Labeled as sample S-2.

Embodiment 3

[0052] Step 1: Weigh 100g of activated alumina and 50g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 20, add it to 1350g of 5%wt sodium metaaluminate solution, and maintain at 80°C for 4h under stirring.

[0053] Step 2: drying the slurry solution obtained in Step 1 at a temperature of 100° C. for 8 hours, and then crushing and grinding to obtain a modified mixed powder.

[0054] Step 3, 120g of mixed powder obtained in step 2 is mixed with 80g of sodium acetate and sodium bicarbonate with a concentration of 0.5%wt, wherein the mass ratio of sodium acetate to sodium bicarbonate is 1:1, mixed and formed to obtain spherical particles, and then in Drying at 100°C, followed by calcination at 200°C for 1h, 450°C for 0.5h, and 550°C for 0.5h to obtain the finished adsorbent. Labeled as sample S-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Channel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com