A kind of preparation method of rare earth modified multi-stage porous titanium silicon molecular sieve

A titanium-silicon molecular sieve and rare earth modification technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc. problems, to avoid rapid growth, fast crystallization speed, and high external specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

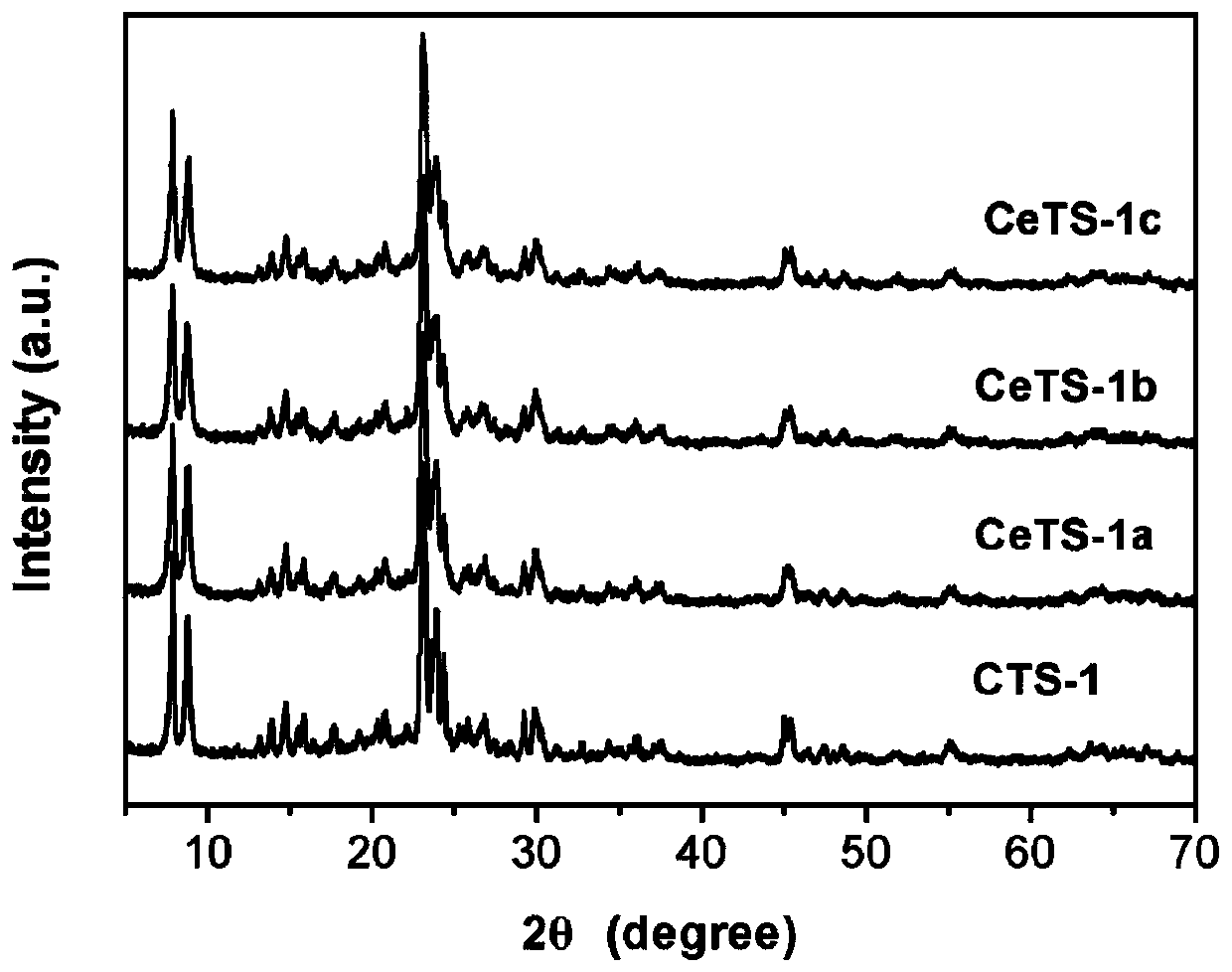

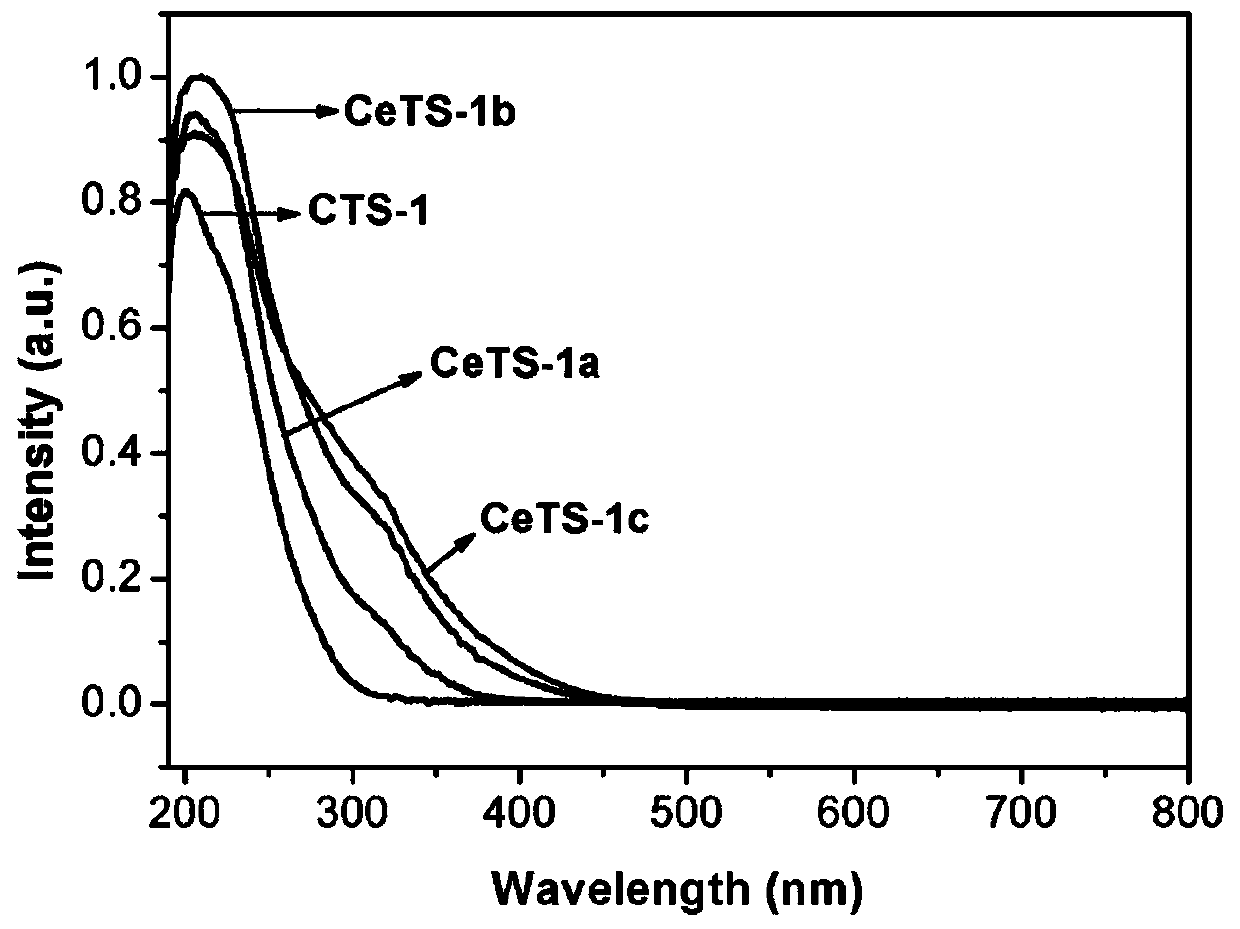

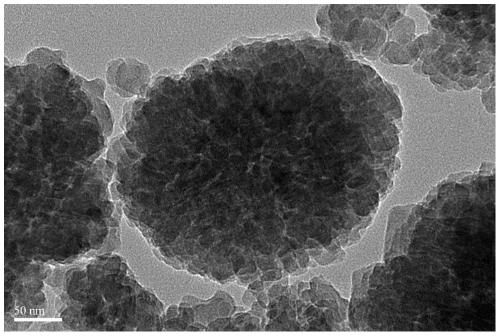

[0033] Under the condition of continuous stirring, the mixture of 14.4g tetrapropylammonium hydroxide (20wt%) and 6.4g water is slowly added in 7.5g tetraethyl orthosilicate, after tetraethyl orthosilicate hydrolysis is complete, obtain Then, the mixed solution B of 0.32g tetrabutyl titanate, 0.004g cerium nitrate and 1.2g isopropanol was slowly added to solution A to obtain colorless and transparent solution C; solution C was removed at 70°C After alcoholing for 2 hours, the solution was transferred to a beaker and dried at 20°C for a certain period of time to obtain a xerogel. After grinding the xerogel, transfer it to a hydrothermal kettle, steam crystallize at 140°C for 24 hours, centrifuge, wash and dry the obtained product overnight, and finally roast the obtained solid at 550°C for 6 hours to finally obtain the rare earth modified A non-hierarchical titanium-silicon molecular sieve named CeTS-1a.

Embodiment 2

[0035] Under the condition of continuous stirring, the mixture of 3.6g tetrapropylammonium hydroxide (20wt%) and 32.0g water is slowly added in 7.5g tetraethyl orthosilicate, after the hydrolysis of tetraethyl orthosilicate is complete, obtain Then, the mixed solution B of 0.32g tetrabutyl titanate, 0.01g cerium nitrate and 1.2g isopropanol was slowly added to solution A to obtain colorless and transparent solution C; solution C was removed at 70°C After alcoholing for 2 hours, the solution was transferred to a beaker and dried at 40°C for a certain period of time to obtain a xerogel. After grinding the xerogel, transfer it to a hydrothermal kettle, steam crystallize at 180°C for 12 hours, centrifuge, wash and dry the obtained product overnight, and finally roast the obtained solid at 550°C for 6 hours to finally obtain the modified rare earth A non-hierarchical titanium-silicon molecular sieve named CeTS-1b.

Embodiment 3

[0037] Under the condition of continuous stirring, the mixture of 14.4g tetrapropylammonium hydroxide (20wt%) and 6.4g water is slowly added in 7.5g tetraethyl orthosilicate, after tetraethyl orthosilicate hydrolysis is complete, obtain Then, the mixed solution B of 0.32g tetrabutyl titanate, 0.4g cerium nitrate and 1.2g isopropanol was slowly added to solution A to obtain colorless and transparent solution C; solution C was removed at 70°C After alcoholing for 2 hours, the solution was transferred to a beaker and dried at 80°C for a certain period of time to obtain a xerogel. After grinding the xerogel, transfer it to a hydrothermal kettle, steam crystallize at 100°C for 72 hours, centrifuge, wash and dry the obtained product overnight, and finally roast the obtained solid at 550°C for 6 hours to finally obtain the modified rare earth A non-hierarchical titanium-silicon molecular sieve named CeTS-1c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com