Preparation method for low-quality diesel hydrofining catalyst

A technology for hydrorefining and inferior diesel oil, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reducing product yield, excessive cracking of alkane components, etc. The effect of hydrogenation saturation and high cetane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

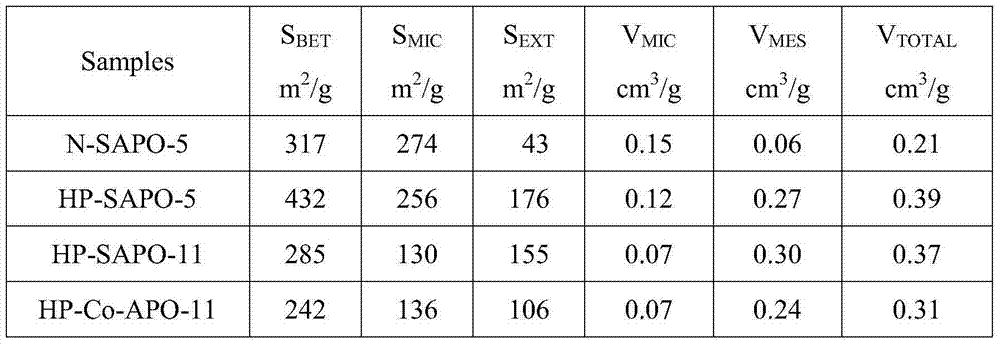

[0022] Add 27.2g of phosphoric acid to 86.4g of deionized water and mix evenly, add 18.6g of pseudo-boehmite, mix uniformly and react for a certain period of time, add 14.8g of template agent triethylamine (TEA) and 5.0g of acidic silica sol, mix evenly to form After the sol, add 25g of 10wt.% hexadecyl trimethoxyorganosilicon ammonium chloride (TPHAC) ethanol solution into the above sol system, transfer the sol to a polytetrafluoroethylene reactor, and keep the temperature in a rotating oven at 185°C Crystallized for 16h. The product is centrifuged, washed and dried to obtain the original SAPO-5 sub-sieve powder. After the original powder was calcined at 580°C for 6 hours, a SAPO-5 molecular sieve with hierarchical channels was obtained, which was marked as HP-SAPO-5.

[0023] Replace 5.0g of acidic silica sol with 6.4g of manganese oxalate, the crystallization time is 36h, and the other reaction conditions are uniformly synthesized to obtain HI-SAPO-5, and the Mn-APO-5 mole...

Embodiment -2

[0027]Add 29.4g of phosphoric acid to 93.3g of deionized water and mix evenly, add 20.5g of pseudo-boehmite, mix uniformly and react for a certain period of time, add 17.8g of template agent triethylamine (TEA) and 5.9g of acidic silica sol, mix evenly to form After the sol, add 25g of 10wt.% TPHAC ethanol solution to the above sol system, transfer the sol to a polytetrafluoroethylene reactor, and crystallize at a constant temperature in a rotating oven at 180°C for 24h. The product is centrifuged, washed and dried to obtain the original SAPO-11 sub-sieve powder. After the original powder was calcined at 600°C for 6 hours, a SAPO-11 molecular sieve with hierarchical channels was obtained, which was marked as HP-SAPO-11.

[0028] Replace 5.0g of acidic silica sol with 7.5g of cobalt oxalate, the crystallization time is 60h, and the other reaction conditions are uniformly synthesized to obtain HI-SAPO-11, and the Co-APO-11 molecular sieve with multi-level channels is obtained, w...

Embodiment -3

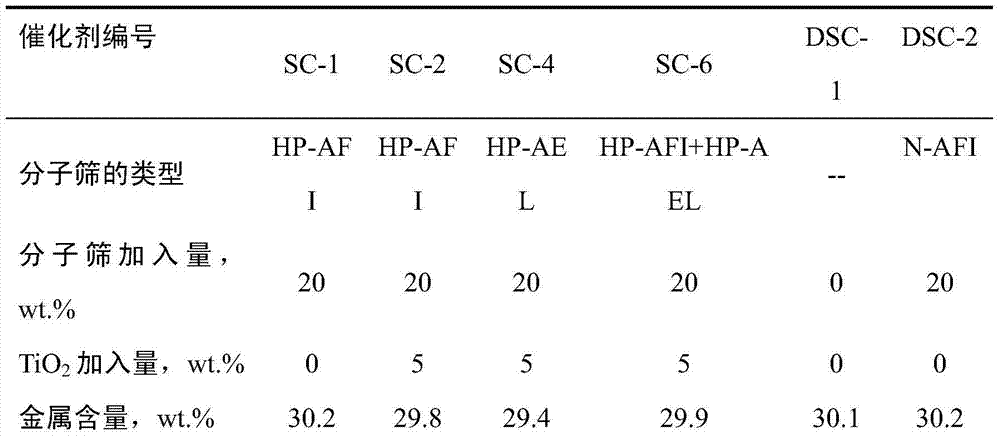

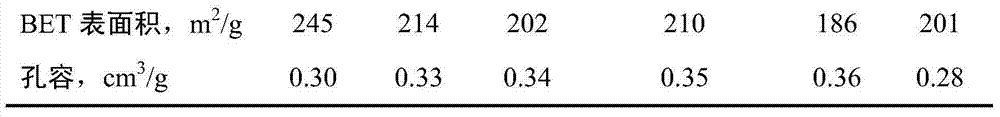

[0034] Mix 40.0g HP-SAPO-5 molecular sieve, 194.0g pseudoboehmite (dry basis content 72%), 20.0g SB powder (dry basis content 75%), 6.0g squash powder and 6.0g methylcellulose Put it into the kneader and knead for 15 minutes, add 205g of acidic solution prepared by water, nitric acid, and citric acid into the dry powder one by one, knead it until it can be extruded, and then squeeze it through an empty plate and a cylindrical orifice plate with a diameter of 8mm. One time, and finally formed into four-leaf clover strips with a diameter of 1.5mm; the obtained wet strips were first cured in an oven at 30°C for 24 hours, then dried in an oven at 120°C for 12 hours, and finally placed in a muffle furnace and the temperature was raised to 550°C for roasting After 4 hours, the vector ZT-1 was obtained.

[0035] Dissolve 4.0g of citric acid, 35.0g of nickel nitrate hexahydrate, 40.0g of ammonium metatungstate, and 24.0g of ammonium heptamolybdate in 60mL of deionized water in turn, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com