A kind of preparation method of high-purity tungsten trioxide

A tungsten trioxide and high-purity technology, applied in the field of preparation of high-purity tungsten trioxide, can solve the problems of large amount of waste water, unstable product quality and high production cost in the production process, and ensure the stability of output and quality. Product output and performance are stable, and the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

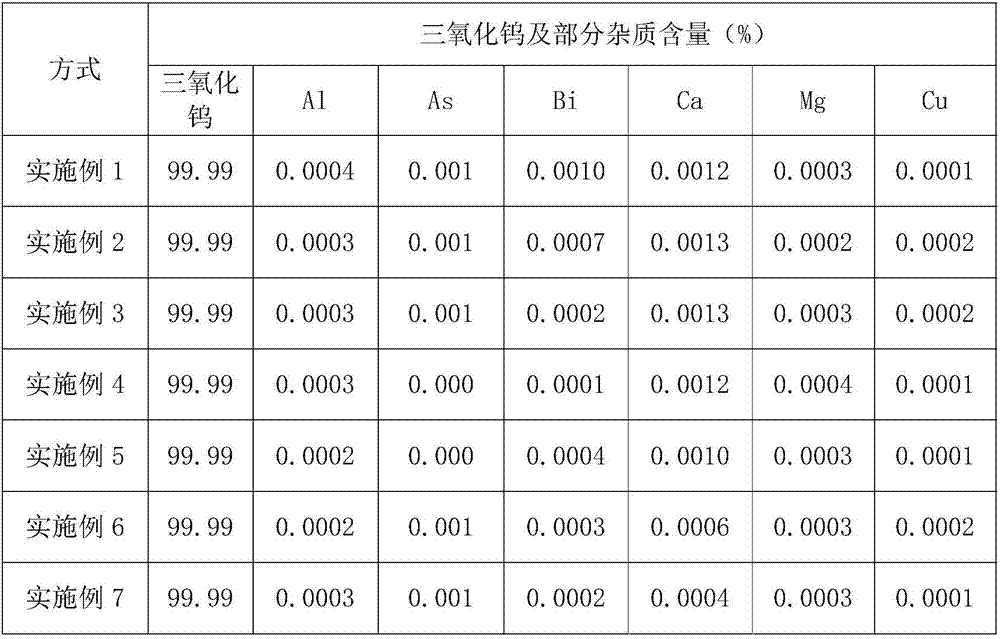

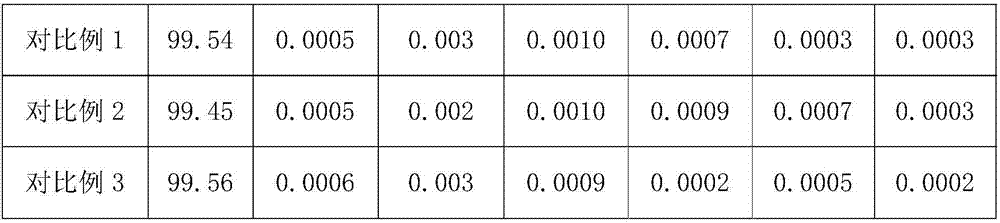

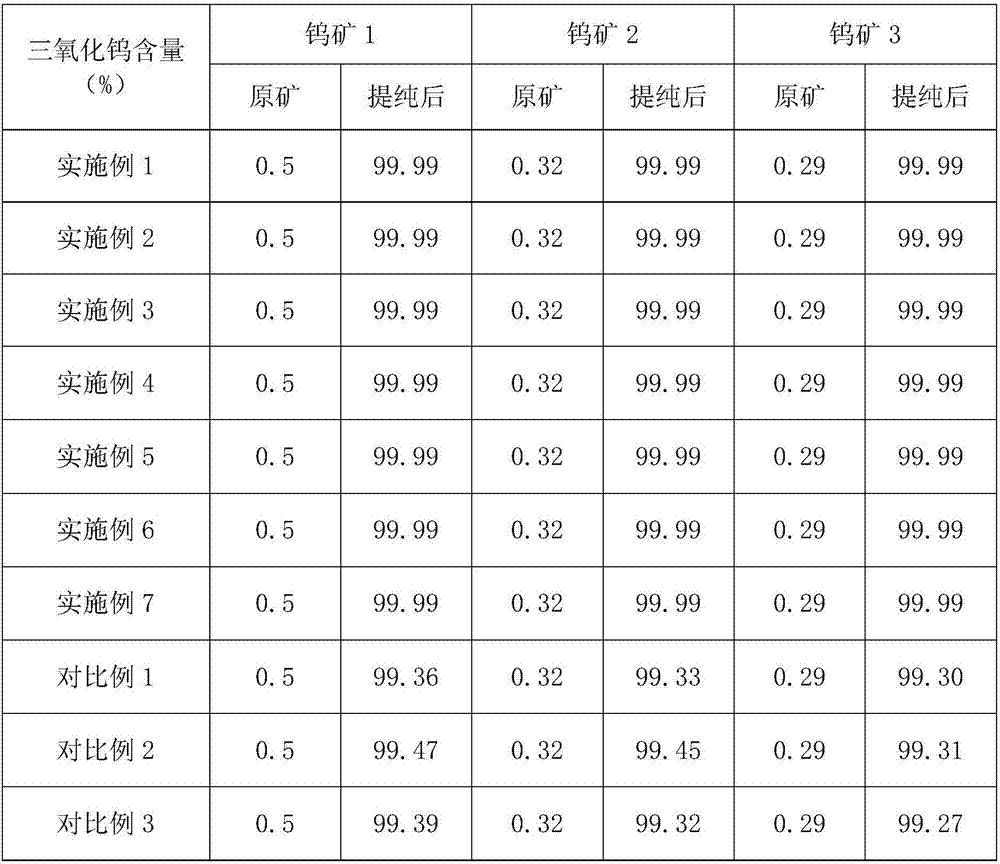

Examples

Embodiment 1

[0037] A preparation method of high-purity tungsten trioxide, comprising the following steps:

[0038] The first step: dissolving, dissolving the tungsten ore with potassium hydroxide solution (mass concentration is 30%) and filtering to remove precipitated impurities;

[0039] The second step: hydrolyzing and precipitating tungsten, adding sulfuric acid to the solution of the first step, the concentration of tungsten in the solution is 10g / L, the pH value is 2.0, the temperature value is 70°C, stirring and reacting for 60 minutes to hydrolyze and precipitate tungsten;

[0040] The third step: filtering, filtering the above solution to obtain tungsten hydrolyzate and acidic waste liquid;

[0041] The fourth step: secondary dissolution, adding deionized water to the tungsten hydrolyzate obtained in the third step, then adding potassium hydroxide solution (mass concentration is 30%), filtering to obtain a tungsten-containing solution, and continuing to the filtrate Add deionize...

Embodiment 2

[0049] A preparation method of high-purity tungsten trioxide, comprising the following steps:

[0050] The first step: dissolving, dissolving the tungsten ore with potassium hydroxide solution (mass concentration is 35%) and filtering to remove precipitated impurities;

[0051] The second step: hydrolyzing and precipitating tungsten, adding sulfuric acid to the solution of the first step, the concentration of tungsten in the solution is 35g / L, the pH value is 2.5, the temperature value is 85°C, stirring and reacting for 70 minutes to hydrolyze and precipitate tungsten;

[0052] The third step: filtering, filtering the above solution to obtain tungsten hydrolyzate and acidic waste liquid;

[0053] The fourth step: secondary dissolution, adding deionized water to the tungsten hydrolyzate obtained in the third step, then adding potassium hydroxide solution (mass concentration is 35%), filtering to obtain a tungsten-containing solution, and continuing to the filtrate Add deionized ...

Embodiment 3

[0061] A preparation method of high-purity tungsten trioxide, comprising the following steps:

[0062] The first step: dissolving, dissolving the tungsten ore with potassium hydroxide solution (mass concentration is 30%) and filtering to remove precipitated impurities;

[0063] The second step: hydrolyzing and precipitating tungsten, adding sulfuric acid to the solution of the first step, the concentration of tungsten in the solution is 35g / L, the pH value is 2.0, the temperature value is 85°C, stirring and reacting for 60 minutes to hydrolyze and precipitate tungsten;

[0064] The third step: filtering, filtering the above solution to obtain tungsten hydrolyzate and acidic waste liquid;

[0065] The fourth step: secondary dissolution, adding deionized water to the tungsten hydrolyzate obtained in the third step, then adding potassium hydroxide solution (mass concentration is 35%), filtering to obtain a tungsten-containing solution, and continuing to the filtrate Add deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com