Method for producing iolite cellular ceramic carrier

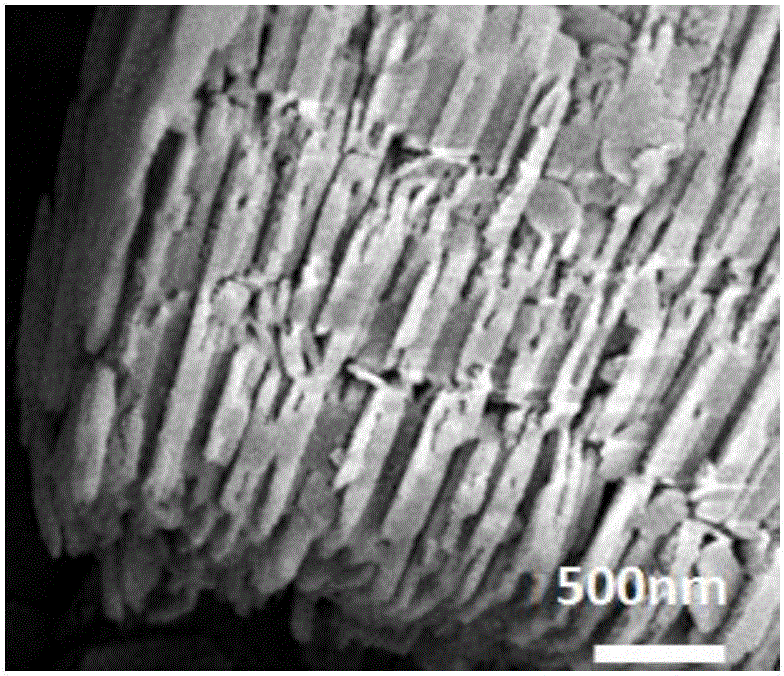

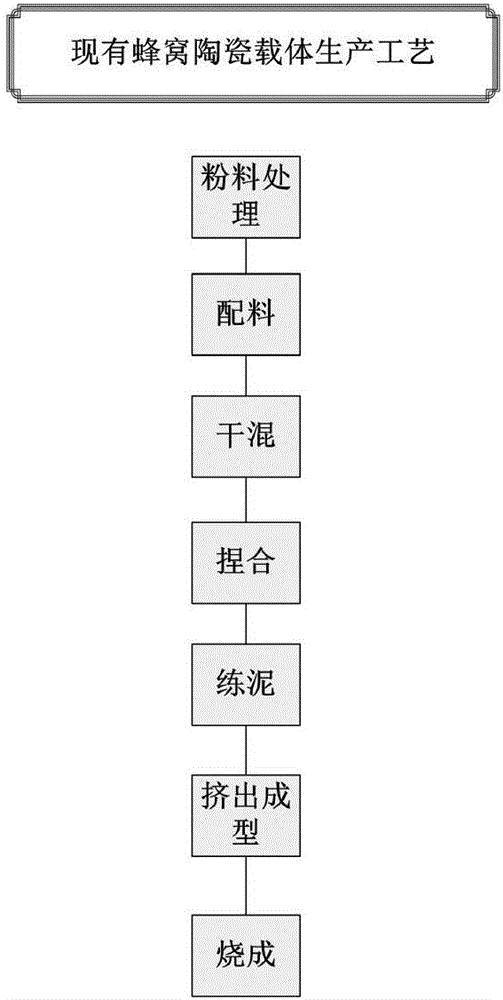

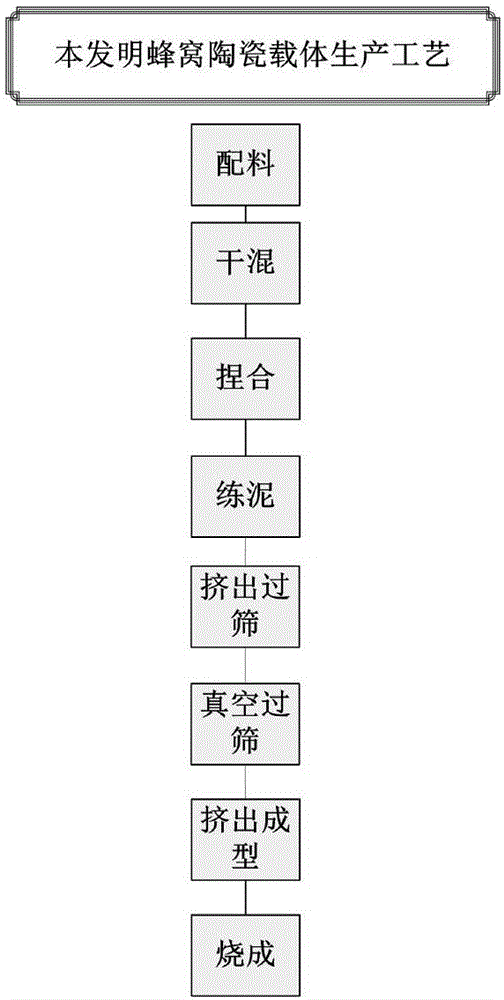

A cordierite honeycomb and ceramic carrier technology, applied in ceramic products, chemical instruments and methods, applications, etc., can solve the problems of incomplete removal of impurities and coarse particles, large dust, low efficiency, etc., to achieve directional growth and energy consumption Low, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Talc, flaky or / and layered raw kaolin and alumina powder are used as raw materials. The particle size and particle size distribution of each raw material meet the powder requirements, and the amount of each raw material meets the content of silica. The content is 50.7wt%, alumina The content of magnesium oxide is 35.8wt%, and the content of magnesium oxide is 13.5wt%. At the same time, R in the raw kaolin 2 The mass content of O ≤ 0.6%, R in talc 2 O mass content ≤ 0.4%, Na in alumina 2 The mass content of O is ≤0.5%, Fe in raw kaolin and talc 2 o 3 and TiO 2 The mass content of all <1.3%.

[0037] The median particle diameter D50 of raw kaolin is 3.0 μm, the median particle diameter D50 of talc is 2.0 μm, and the median particle diameter D50 of alumina is 2.0 μm.

[0038] Get each powder raw material, produce ceramic carrier according to the following method:

[0039] (1) Add the powder raw materials into the large-scale gravity-free mixing equipment according t...

Embodiment 2

[0044] Talc, flaky or / and layered raw kaolin and alumina powder are used as raw materials. The particle size and particle size distribution of each raw material meet the powder requirements, and the amount of each raw material meets the content of silica. The content is 50.7wt%, alumina The content of magnesium oxide is 35.8wt%, and the content of magnesium oxide is 13.5wt%. At the same time, R in the raw kaolin 2 The mass content of O ≤ 0.6%, R in talc 2 O mass content ≤ 0.4%, Na in alumina 2 The mass content of O is ≤0.5%, Fe in raw kaolin and talc 2 o 3 and TiO 2 The mass content of all <1.3%.

[0045] The median particle diameter D50 of raw kaolin is 3.0 μm, the median particle diameter D50 of talc is 2.0 μm, and the median particle diameter D50 of alumina is 2.0 μm.

[0046] Get each powder raw material, produce ceramic carrier according to the following method:

[0047] (1) Add the powder raw materials into the large-scale gravity-free mixing equipment according t...

Embodiment 3

[0052] Talc, flaky or / and layered raw kaolin and alumina powder are used as raw materials. The particle size and particle size distribution of each raw material meet the powder requirements, and the amount of each raw material meets the content of silica. The content is 50.7wt%, alumina The content of magnesium oxide is 35.8wt%, and the content of magnesium oxide is 13.5wt%. At the same time, R in the raw kaolin 2 The mass content of O ≤ 0.6%, R in talc 2 O mass content ≤ 0.4%, Na in alumina 2 The mass content of O is ≤0.5%, Fe in raw kaolin and talc 2 o 3 and TiO 2 The mass content of all <1.3%.

[0053] The median particle diameter D50 of raw kaolin is 3.0 μm, the median particle diameter D50 of talc is 2.0 μm, and the median particle diameter D50 of alumina is 2.0 μm.

[0054] Get each powder raw material, produce ceramic carrier according to the following method:

[0055] (1) Add the powder raw materials into the large-scale gravity-free mixing equipment according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com