A modified zinc oxide, its preparation method and its application in rubber products

A technology for rubber products and zinc oxide, which is applied in the field of rubber products, can solve the problems of increasing the disassembly and cleaning work of the foaming head, difficult to accurately control the flow of the pipeline, and reducing the production efficiency, and the operation conditions are easy to control, and the preparation method Simple and feasible, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

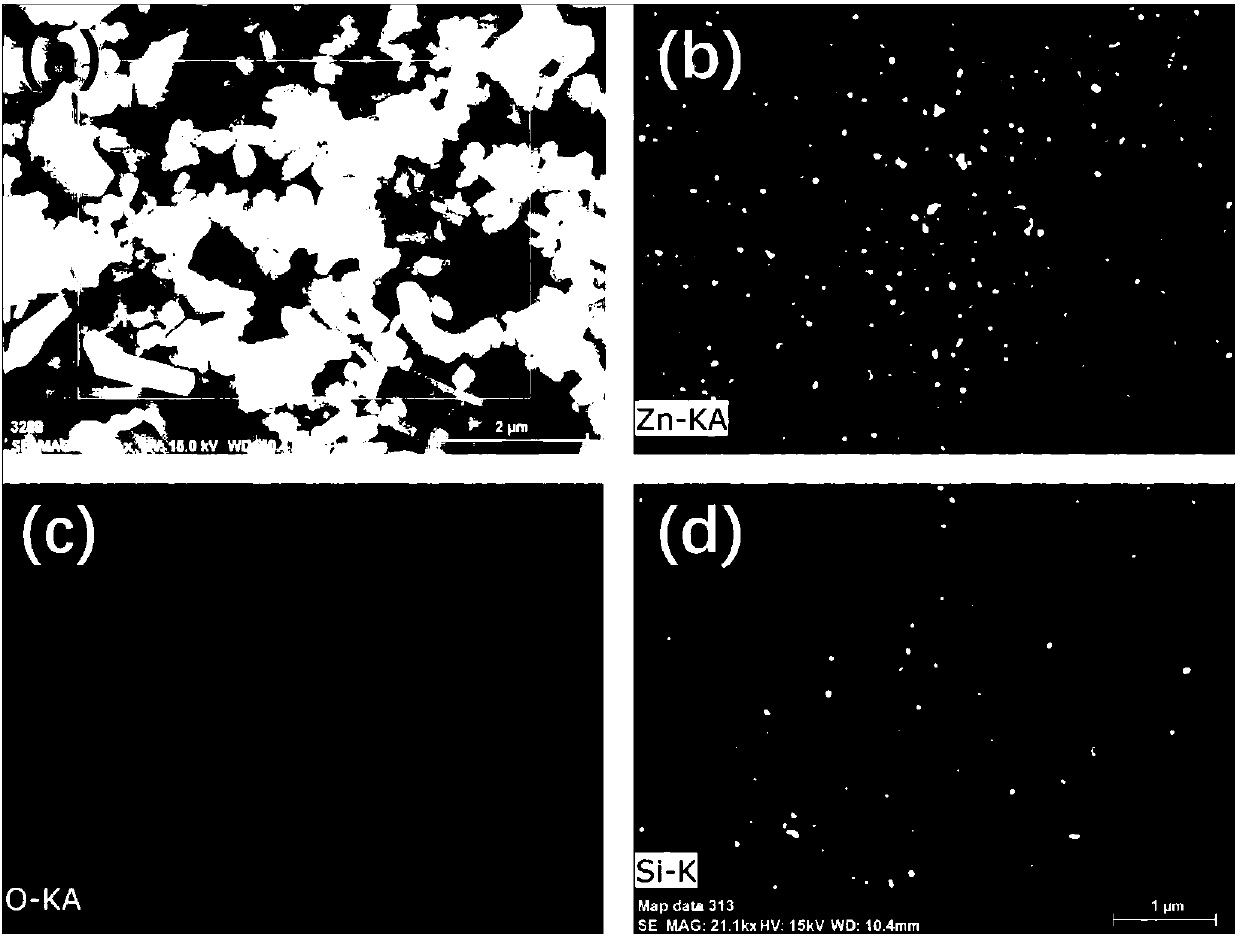

Image

Examples

Embodiment Construction

[0018] The modified zinc oxide in the present invention includes the following components by weight: 8-15 parts of water, 0.01-0.1 parts of sodium hydroxide, 2-6 parts of zinc oxide and 0.5-2 parts of tetraethyl orthosilicate.

[0019] The first optimized embodiment is: the components are: 8 parts of water, 0.02 part of sodium hydroxide, 3 parts of zinc oxide and 0.5 part of tetraethyl orthosilicate; the performance of the modified zinc oxide in such a ratio is the best.

[0020] The second optimized embodiment is: the components are: 10 parts of water, 0.05 parts of sodium hydroxide, 5 parts of zinc oxide and 1 part of tetraethyl orthosilicate; the performance of the modified zinc oxide in such a ratio is the best.

[0021] The third optimized embodiment is: the components are: 15 parts of water, 0.1 part of sodium hydroxide, 6 parts of zinc oxide and 2 parts of tetraethyl orthosilicate; the performance of the modified zinc oxide in such a ratio is the best.

[0022] A prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com