Coupling energy saving device for multiple products of sintering procedure

A technology of sintering process and energy-saving device, which is applied in the direction of steam engine device, combustion method, energy efficiency improvement, etc. It can solve the waste heat resource waste and other problems, achieve the increase of power generation, optimize the flue gas flow rate and the layout of heat exchange surface, and improve the waste heat The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in combination with specific embodiments.

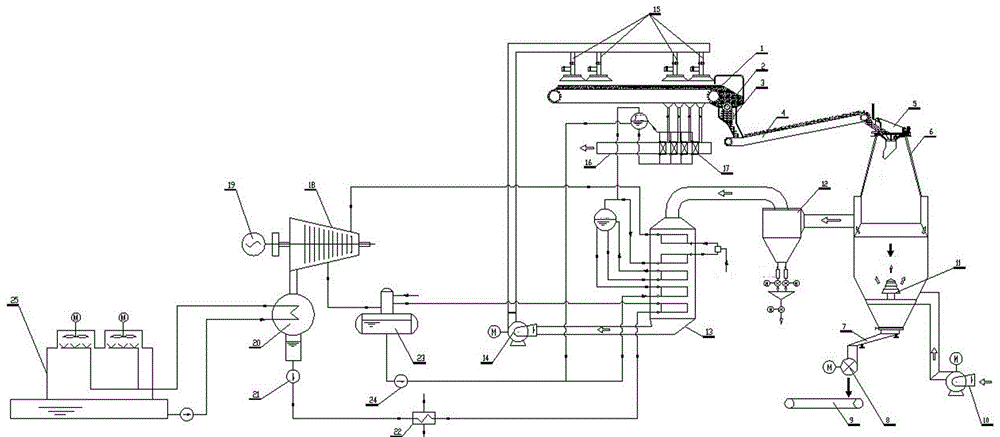

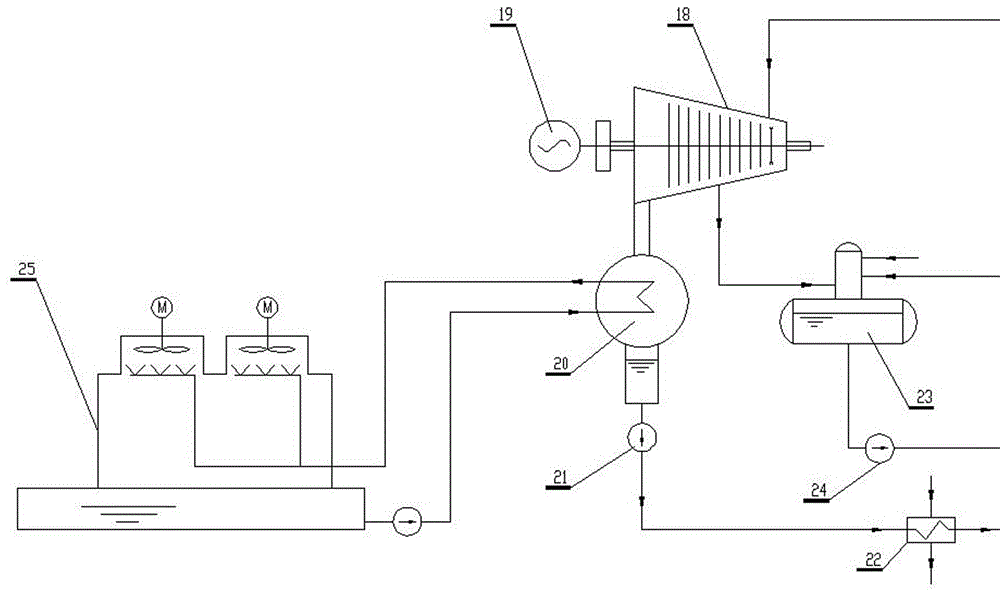

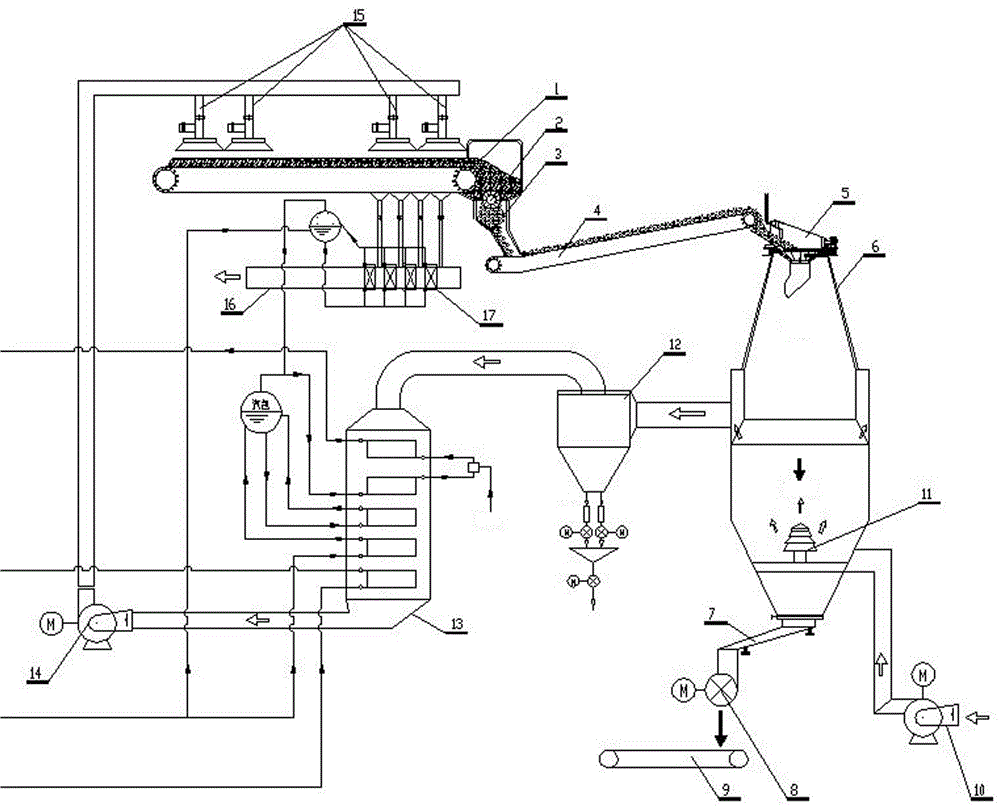

[0028] As shown in the figure: a multi-product coupling energy-saving device in the sintering process, including a sinter sensible heat efficient furnace cold utilization system, a hot air sintering system, a sintering large flue waste heat utilization system, and a power generation system; the sinter sensible heat is highly efficient Furnace cooling utilization system includes sintering machine 1, single roll crusher 2 installed at the tail of sintering machine 1, reclaim valve 3, chain conveyor 4, cooling furnace 6, blower 10, cyclone dust collector 12, waste heat boiler 13 and induced draft fan 14. The lower part of the single roll crusher 2 is provided with a retrieving valve 3, the lower part of the retrieving valve 3 is connected to one end of the chain conveyor 4, and the other end of the chain conveyor 4 is connected to the cooling furnace 6; the air inlet of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com