External application unguent preparation and use method

A technology for external application of ointment and medicinal powder, which is applied in the fields of medical formula, ointment delivery, and drug delivery. The effect of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

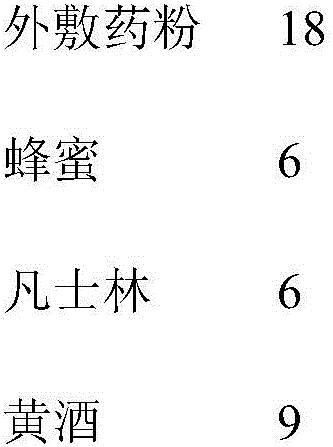

Embodiment 1

[0036] Prepare the following components in parts by weight:

[0037] External application powder for treating synovitis: 18 parts, 200 mesh

[0038] Honey: 6 servings

[0039] Vaseline: 6 servings

[0040] Rice wine: 9 servings

[0041] Mix the above components and stir evenly to form a paste for external application ointment.

Embodiment 2

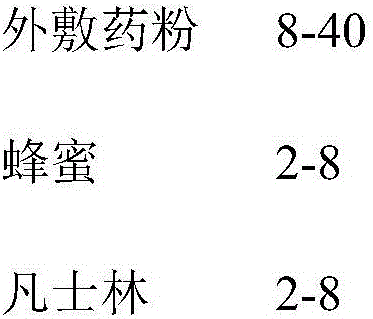

[0043] Prepare the following components in parts by weight:

[0044] External application powder for treating synovitis: 8 parts, 200 mesh

[0045] Honey: 2 servings

[0046] Vaseline: 2 servings

[0047] Rice wine: 3 servings

[0048] Mix the above components and stir evenly to form a paste for external application ointment.

Embodiment 3

[0050] Prepare the following components in parts by weight:

[0051] External application powder for treatment of rheumatoid arthritis: 40 parts, 200 mesh

[0052] Honey: 8 servings

[0053] Vaseline: 8 servings

[0054] Rice wine: 20 servings

[0055] Mix the above components and stir evenly to form a paste for external application ointment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com