Aluminum alloy paddle profile and manufacturing process thereof

A production process, aluminum alloy technology, applied in the aviation field, can solve the problems of manufacturing cost and long cycle, achieve the effect of convenient operation, simple and stable process, and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

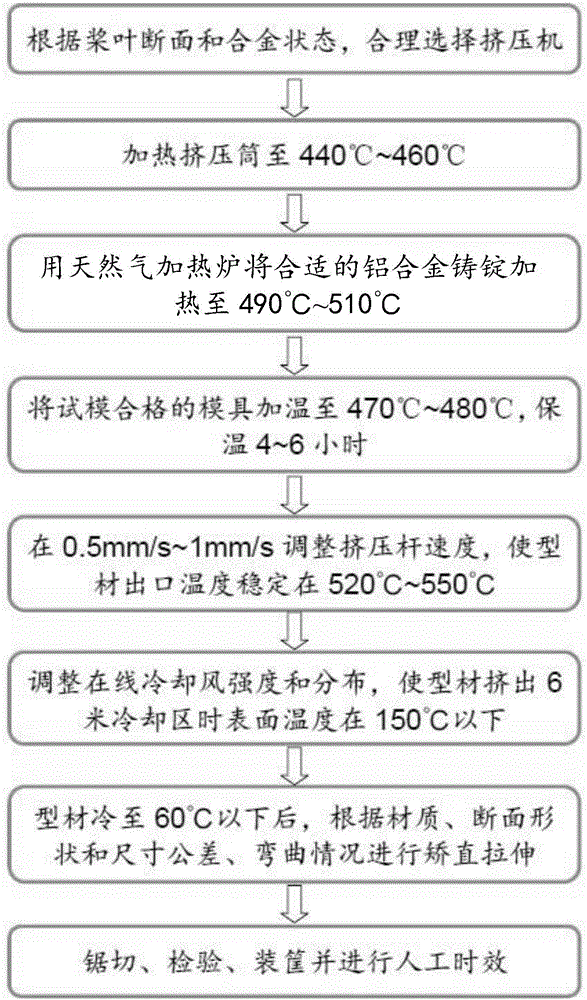

[0030] This embodiment proposes an aluminum alloy blade profile, which adopts figure 1 The process flow shown is made by the following steps:

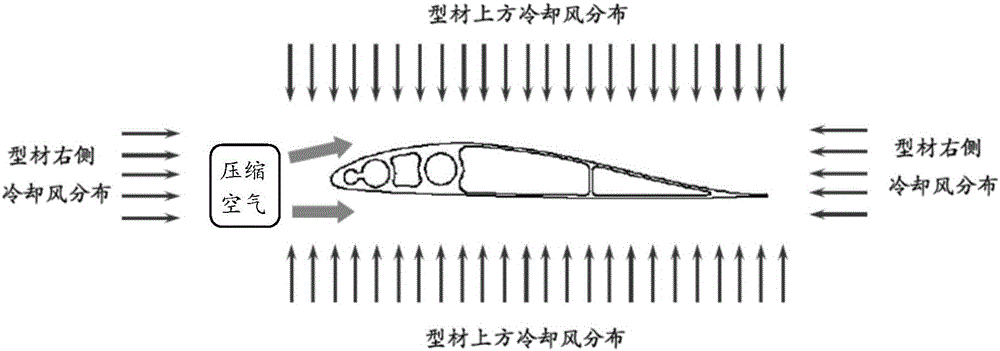

[0031] S1. The width direction of the aluminum alloy blade profile to be manufactured is 198.39mm, the height direction is 24mm, and the cross-sectional area is 924.4mm 2 , in order to control the extrusion ratio between 30 and 60, an extruder with a corresponding diameter of the extrusion cylinder is selected for extrusion, and the extrusion ratio is calculated to be 46.84, which meets the extrusion requirements. The extrusion machine is equipped with an online air-cooled quenching device, which can meet the production requirements of 6005A-T6 state. Therefore, the forward extrusion machine equipped with an online strong wind cooling and quenching device is selected to produce the aluminum alloy blade profile.

[0032] S2. Raise the temperature of the extrusion barrel to 440-460°C. When the embodiment is carried out, the extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com