Nitrogen balance cylinder system for weight balance of machine tool

A technology of balance cylinder and nitrogen, which is applied in the direction of maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of heavy load of the lifting drive mechanism, poor response characteristics, rising oil temperature of the hydraulic circuit, etc., and achieve compactness Occupies space, small pressure change, stable balance force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

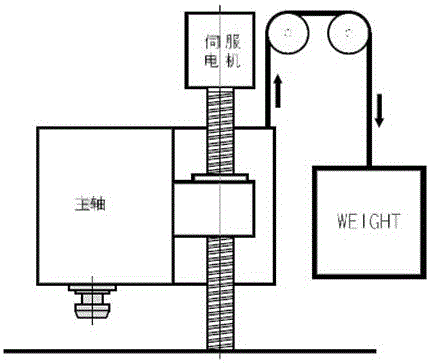

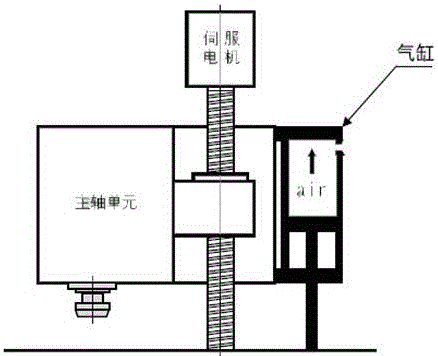

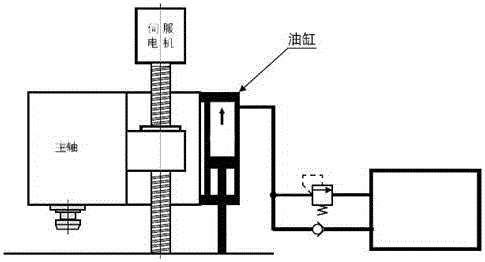

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] The present invention relates to a nitrogen cylinder 1, a controller 2, a nitrogen balancer 3, a ball screw 4, a servo motor 5, a ball screw nut 6, a machine tool spindle 7, a body 8, a connecting block 9, a protection plate 10, a piston rod 11, Technical features such as floating support plate 12, sleeve 13, etc.

[0024] like Figure 4 As shown, a nitrogen gas balancer is used for the spindle assembly of machine tools, and includes a body with a cylinder structure. The top of the body is provided with a gas filling port, and the end of the body is provided with a sleeve. The sleeve is integrally formed with a There is a flange plate with a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com