Gas sensor, array and a method for manufacturing thereof

A gas sensor and sensor technology, which can be used in the structural details of gas analyzers, semiconductor/solid-state device manufacturing, and electrical solid-state devices, etc., and can solve problems such as inapplicable and unsuitable gas sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

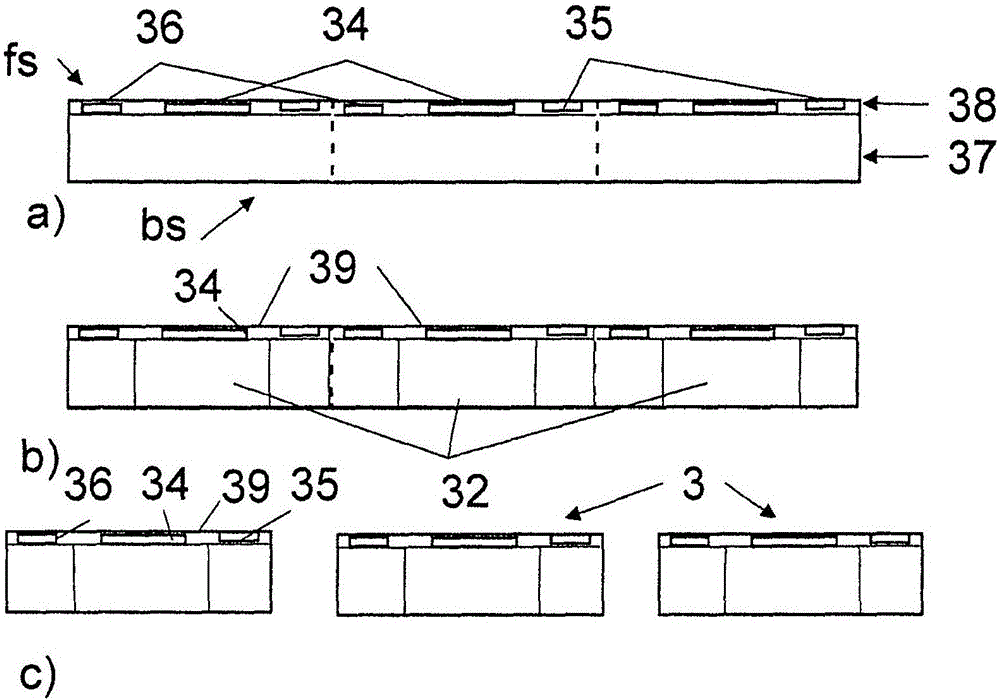

[0038] figure 1 Manufacturing steps applied in a method of manufacturing a gas sensor according to an embodiment of the present invention are shown in schematic diagrams a) to c). These steps refer to the fabrication of a suitable gas sensor chip that will later be packaged into the gas sensor. in gesture figure 1 In a), a wafer is provided which contains a semiconductor substrate 37 and a layer stack 38 arranged on the semiconductor substrate 37 at the front side fs of the wafer. As such, the wafer may be a standard CMOS wafer into which integrated processing circuitry 36 and contact pads 35 are fabricated. The vertical dashed lines within the wafer represent the scribe trenches along which the wafer will later be diced into a plurality of gas sensor chips. In addition to pads 35 and data processing circuits 36 , heaters 34 may be fabricated on the front side fs of the wafer, for example incorporated into one of the patterned metal layers of layer stack 38 .

[0039] prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com