Device and method for efficiently treating wastewater

A waste water treatment, high-efficiency technology, applied in the field of water treatment, can solve the problems of inability to treat waste water nitrate in depth, increase the cost of electric energy, and difficult to control the reaction, and achieve the effects of cost reduction, increase of C/N ratio, and enhanced enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is to treat a certain 3000m3 / d fine chemical wastewater, wastewater (anaerobic effluent) water quality: COD: 840-950mg / L, NH 4 + -N: 70-95mg / L, TN: 130-165mg / L, pH value: 6-8, temperature 22°C-28°C.

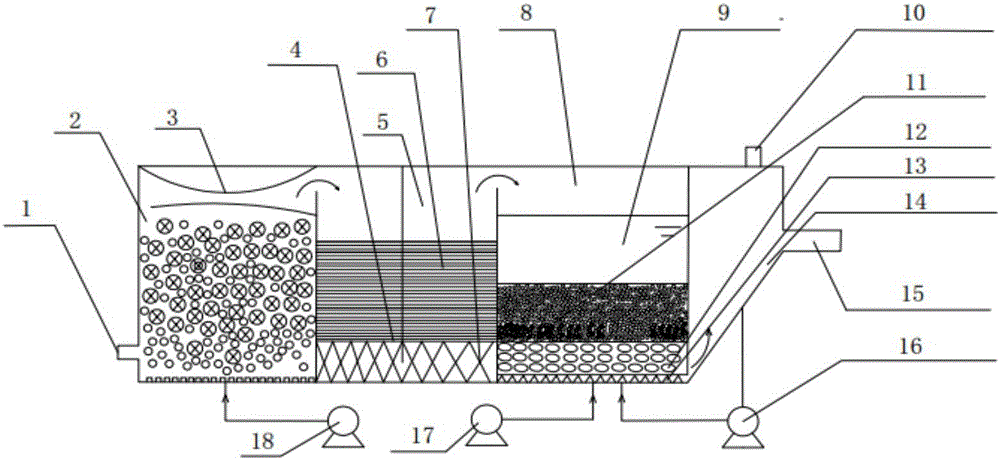

[0027] like figure 1 A kind of high-efficiency wastewater treatment device shown comprises MBBR reaction zone 2, solid-phase carbon source zone 5, denitrification filter tank zone 8 and buffer zone 14, and said MBBR reaction zone 2 is provided with guide device 3, said The diversion device 3 is a smooth cylindrical pipe that shrinks in the middle and expands at both ends. The inside of the MBBR reaction zone 2 is filled with organic biofilm carriers in a suspended form, with a filling ratio of 40%, an outer diameter of 15mm, and a density of 0.94g / cm 3, The MBBR reaction zone 2 communicates with the water inlet 1; the inside of the solid-phase carbon source zone 5 is sequentially filled with a distiller's grains layer 6 and a loofah layer 7, and a porou...

Embodiment 2

[0036] This embodiment is to process a certain 2600m 3 / d Comprehensive wastewater in chemical industry park, wastewater (anaerobic effluent) water quality: COD: 980-1230mg / L, NH 4 + -N: 114-135mg / L, TN: 262-285mg / L, pH value: 7-9, temperature 19°C-26°C.

[0037] like figure 1 A kind of high-efficiency wastewater treatment device shown comprises MBBR reaction zone 2, solid-phase carbon source zone 5, denitrification filter tank zone 8 and buffer zone 14, and said MBBR reaction zone 2 is provided with guide device 3, said The diversion device 3 is a smooth cylindrical pipe that shrinks in the middle and expands at both ends. The inside of the MBBR reaction zone 2 is filled with organic biofilm carriers in a suspended form, with a filling ratio of 50%, an outer diameter of 25mm, and a density of 0.96g / cm 3, The MBBR reaction zone 2 communicates with the water inlet 1; the inside of the solid-phase carbon source zone 5 is sequentially filled with a distiller's grains layer 6...

Embodiment 3

[0046] This embodiment is to process a certain 1200m 3 / d Pharmaceutical wastewater, wastewater (anaerobic effluent) water quality: COD: 1010-1270mg / L, NH 4 + -N: 96-112mg / L, TN: 185-243mg / L, pH value: 6-8, temperature 20°C-27°C.

[0047] like figure 1 A kind of high-efficiency wastewater treatment device shown comprises MBBR reaction zone 2, solid-phase carbon source zone 5, denitrification filter tank zone 8 and buffer zone 14, and said MBBR reaction zone 2 is provided with guide device 3, said The diversion device 3 is a smooth cylindrical pipe that shrinks in the middle and expands at both ends. The inside of the MBBR reaction zone 2 is filled with organic biofilm carriers in a suspended form. The filling ratio is 60%, the outer diameter is 35mm, and the density is 0.98g / cm 3, The MBBR reaction zone 2 communicates with the water inlet 1; the inside of the solid-phase carbon source zone 5 is sequentially filled with a distiller's grains layer 6 and a loofah layer 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com