Water purification system and control method thereof

A water purification system and control method technology, applied in water treatment parameter control, chemical instruments and methods, multi-stage water treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

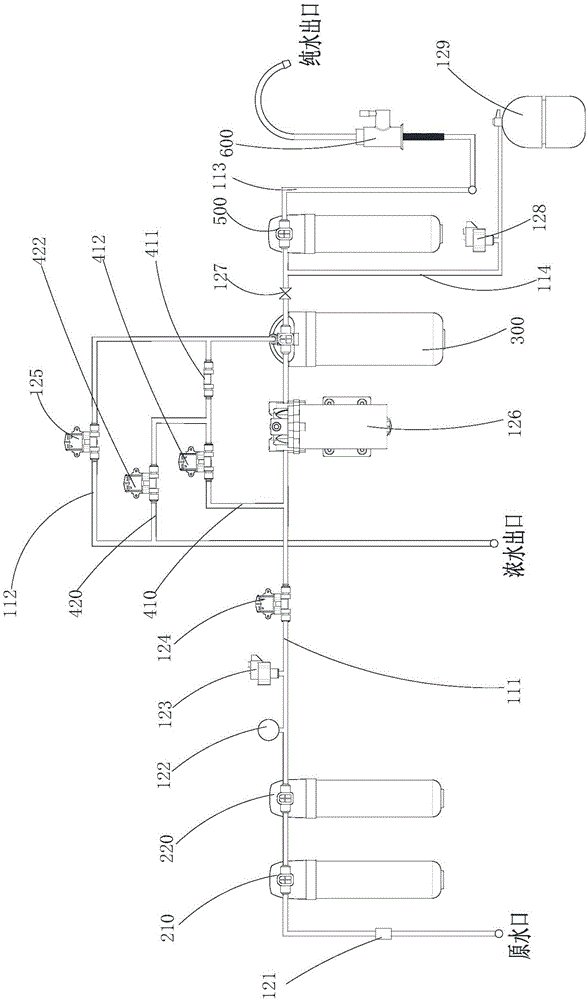

Examples

Embodiment 2

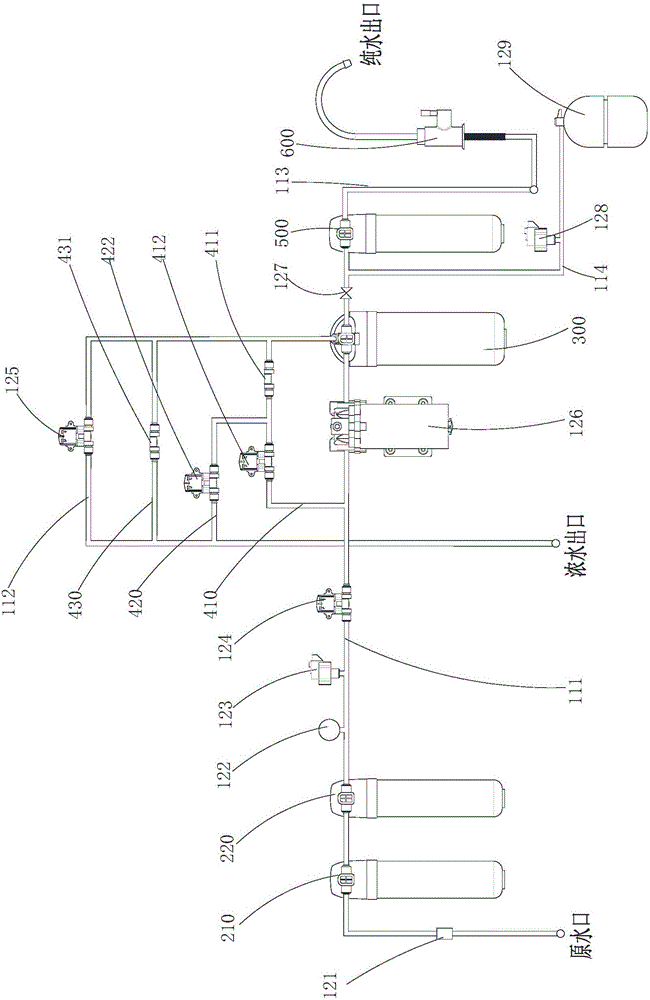

[0116] see figure 2 As shown, the difference between Embodiment 2 of the present invention and Embodiment 1 is that the concentrated water discharge control unit also includes a third branch 430, and the water inlet end of the third branch 430 is connected to the concentrated water outlet of the reverse osmosis membrane treatment unit 300. On the concentrated water pipeline 112 between the concentrated water discharge solenoid valve 125, the water outlet end of the third branch 430 is connected to the water outlet section of the concentrated water pipeline 112 or directly emptied, and the third branch 430 is provided with a third Wastewater ratio 431.

[0117] Correspondingly, the control method of the above-mentioned water purification system provided by the present invention is different from Embodiment 1 in that:

[0118] S200: When the water purification system produces water, control the concentrated water discharge control unit to cycle between the first operation mode...

Embodiment 3

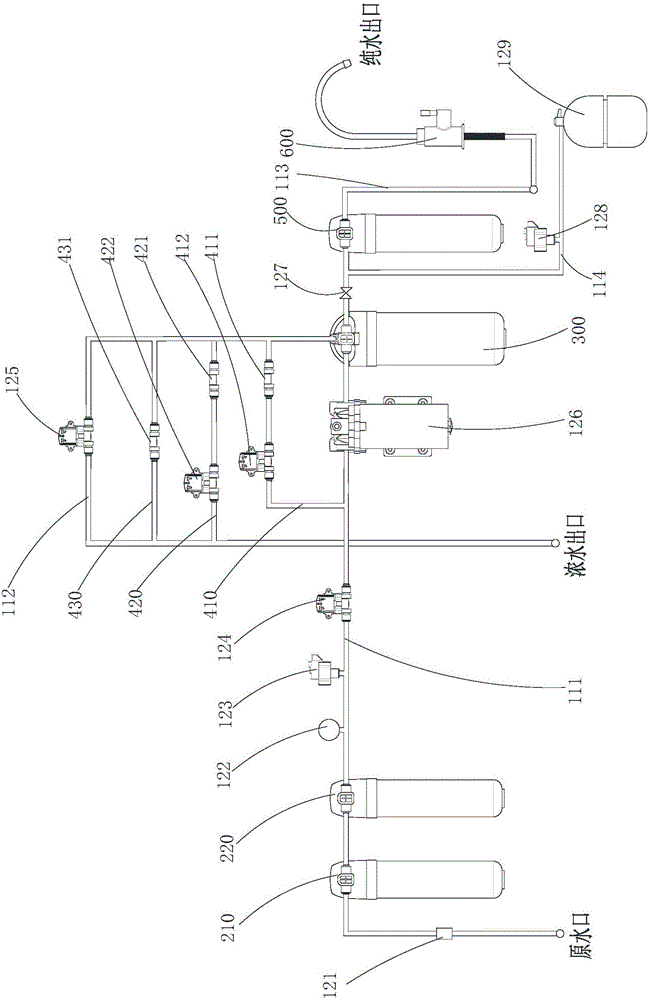

[0128] see image 3 As shown, the difference between the third embodiment of the present invention and the second embodiment is that the wastewater ratio component of the concentrated water discharge control unit also includes a second wastewater ratio 421 .

[0129] The water inlet end of the first branch 410 is connected to the water outlet end of the first waste water ratio 411, and the water inlet end of the first waste water ratio 411 is connected to the outlet between the concentrated water outlet of the reverse osmosis membrane treatment unit 300 and the concentrated water discharge solenoid valve 125. On the concentrated water pipeline 112; the water inlet end of the second branch 420 is connected to the water outlet end of the second waste water ratio 421, and the water inlet end of the second waste water ratio 421 is connected to the concentrated water outlet of the reverse osmosis membrane treatment unit 300 and the concentrated water discharge On the concentrated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com