Integrated aerobic fermentation equipment

A technology of aerobic fermentation and fermentation equipment, which is applied in climate change adaptation, organic fertilizer preparation, chemical fertilizer treatment heating/cooling, etc. It can solve the problems of poor aeration sealing, high failure rate, and large volume, and achieve reliability improvement , avoid easy breakage, and reduce the effect of operating personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

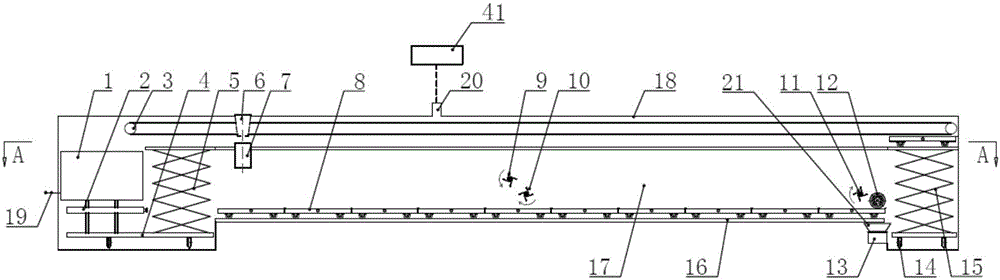

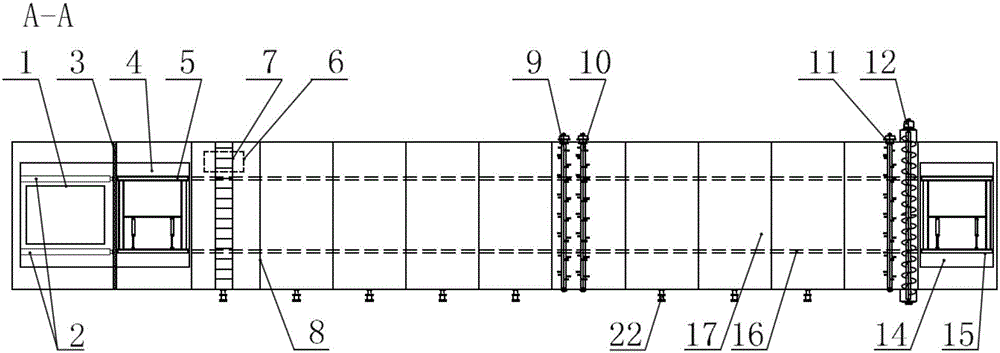

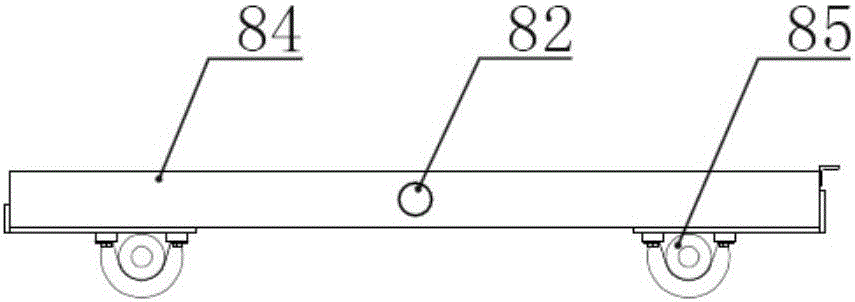

[0023] see Figure 1 to Figure 5 , the integrated aerobic fermentation equipment of the present invention includes a tunnel-type bin body 17 for storing fermented materials, the top of the bin body 17 is a top cover 18, and the air induction pipe 20 and the deodorization system 41 are passed through the top cover 18 connect. The bottom of the bin body 17 is equipped with two parallel rails 16, and a plurality of aeration trolleys 8 are arranged on the rails 16; on one side of the rails 16, a plurality of aerators corresponding to the air inlets 82 on the sides of the aeration trolleys 8 are provided. gas device 22 (see figure 2 ), the aeration device 22 adopts a blower fan as the aeration power. The gas inlet of the aeration device 22 is connected with the outlet of the air preheater 1 through the aeration pipeline 19, and the gas outlet of the aeration device 22 is a telescopic structure, which is controlled by the control system to expand and contract with the air inlet 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com