Single-layer micro-nano double-scale enhanced boiling heat transfer copper surface structure and preparing method thereof

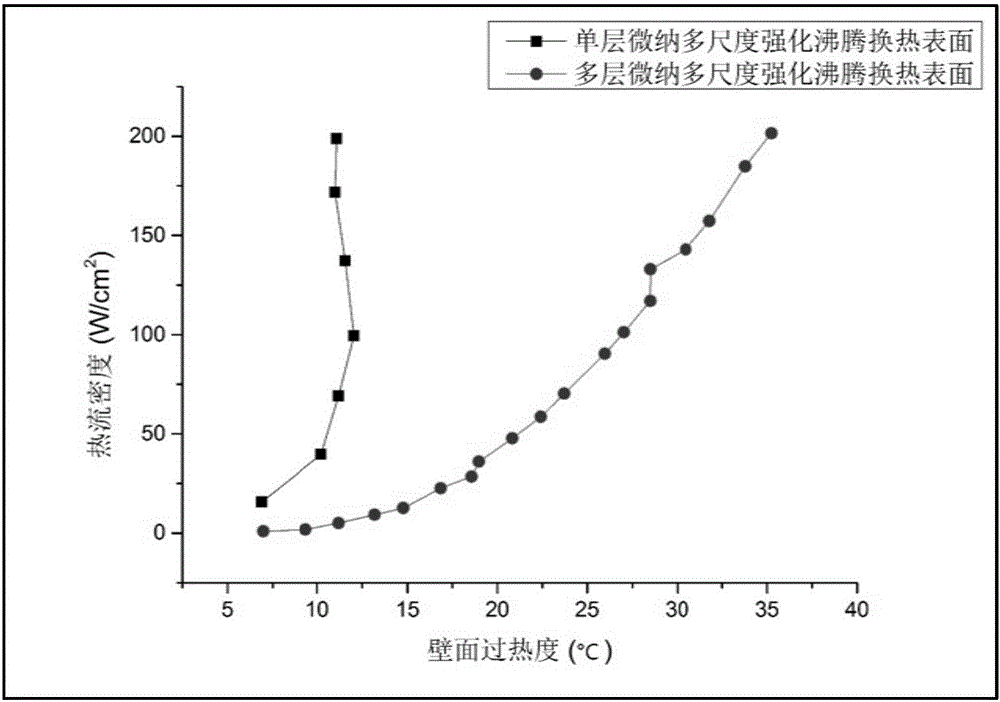

A technology to strengthen boiling and surface structure, applied in the field of material science, can solve the problems of low wall superheat and high wall superheat, and achieve the effect of low wall superheat, short generation cycle and good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Surface pretreatment: Use dilute sulfuric acid solution, hot alkali solution, and deionized water to clean the surface oxide and oil stains on the copper substrate.

[0028] (2) Surface deposition: the copper substrate is used as the cathode, and the copper sheet is used as the anode, and put into the electrolyte solution with a solution ratio of 1.0M sulfuric acid and 0.4M copper sulfate. Through direct current, keep the cathode current density at 1A / cm 2 , The electrodeposition reaction time is 30s.

[0029] (3) Sample sintering: Under the protection of reducing atmosphere, heat treatment is carried out at a sintering temperature of 710°C to enhance the mechanical strength of the product, thereby obtaining samples.

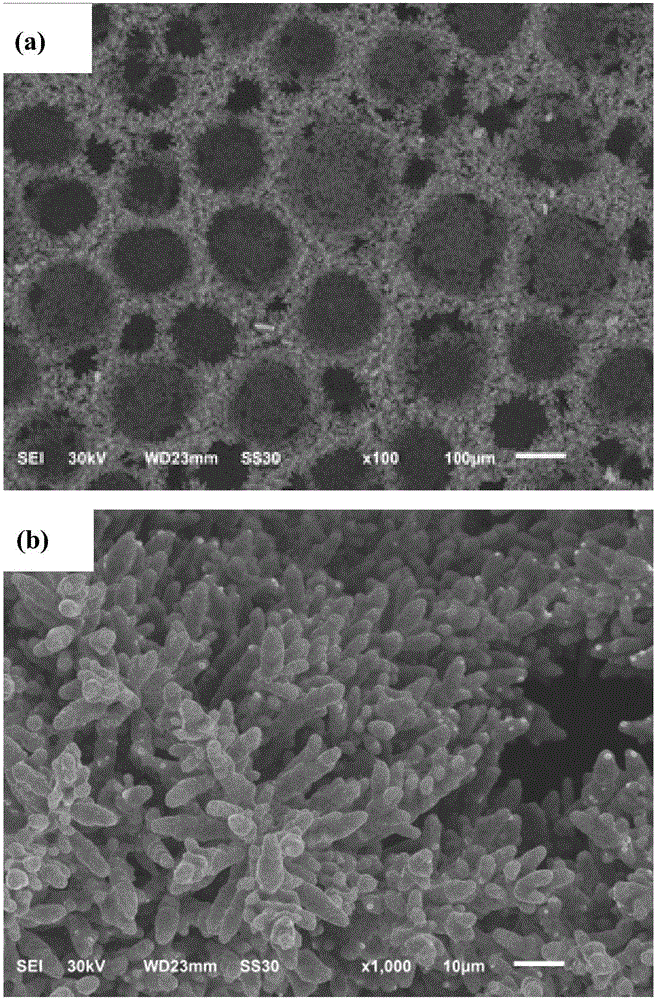

[0030] Such as figure 1 As shown, the copper surface is a single-layer surface structure composed of micron macropores and pore walls with nanopores. The pore size of the micron macropores is substantially the same at the bottom and the top. The p...

Embodiment 2

[0032] (1) Surface pretreatment: Use dilute sulfuric acid solution, hot alkali solution, and deionized water to clean the surface oxide and oil stains on the copper substrate.

[0033] (2) Surface deposition: the copper substrate is used as the cathode, and the copper sheet is used as the anode, and put into the electrolyte solution with a solution ratio of 1.5M sulfuric acid and 0.1M copper sulfate. Through direct current, keep the cathode current density at 0.5A / cm 2 , The electrodeposition reaction time is 200s.

[0034] (3) Sample sintering: Under the protection of reducing atmosphere, heat treatment is carried out, and the sintering temperature is 410°C to enhance the mechanical strength of the product, so as to obtain samples, electron microscope images and figure 1 Basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com