Pure polyester spinning finisher

An oil and spinning technology, applied in the field of pure polyester spinning oil, can solve the problems of high fiber friction, yarn bifurcation, end breakage, etc., and achieve the effects of reducing cost, improving coverage and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

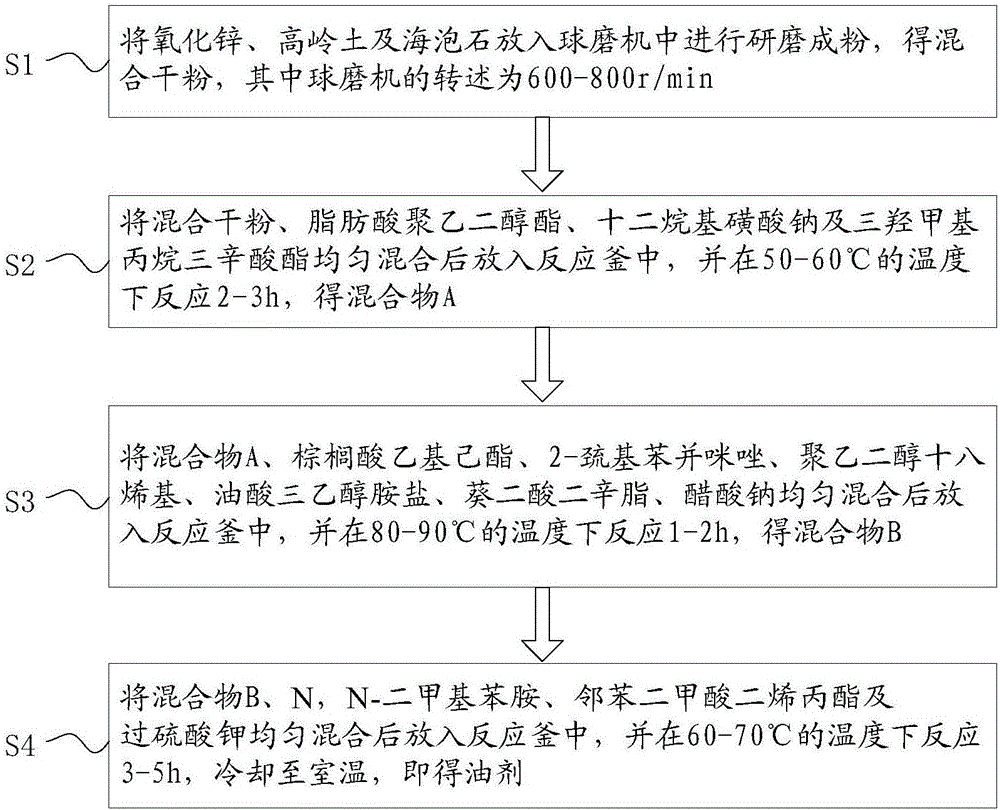

Method used

Image

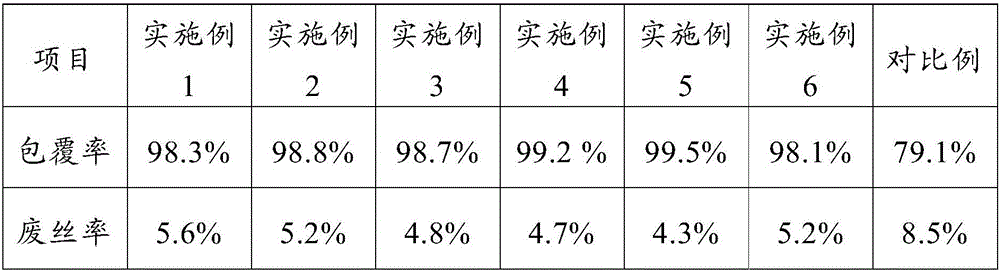

Examples

Embodiment 1

[0028] This embodiment provides a kind of oil agent for pure polyester spinning, comprising following components:

[0029] Fatty acid polyethylene glycol esters,

[0030] Sodium dodecyl sulfonate,

[0031] trimethylolpropane tricaprylate,

[0032] Kaolin,

[0033] meerschaum,

[0034] Ethylhexyl palmitate,

[0035] 2-Mercaptobenzimidazole,

[0036] Polyethylene glycol octadecenyl,

[0037] Oleic acid triethanolamine salt,

[0038] Dioctyl Sebacate,

[0039] Sodium acetate,

[0041] N,N-Dimethylaniline,

[0042] diallyl phthalate,

[0043] Potassium persulfate,

[0044] In terms of parts by weight, the parts by weight of the above-mentioned components are in order: 20 parts, 14 parts, 3 parts, 0.5 parts, 0.5 parts, 32 parts, 9 parts, 11 parts, 8 parts, 26 parts, 10 parts, 1 Servings, 8 servings, 9 servings, 8 servings.

[0045] Among them, the particle size of kaolin is 30-80nm, the particle size of sepiolite is 50-100nm, the particle size of ...

Embodiment 2

[0052] This embodiment provides a kind of oil agent for pure polyester spinning, comprising following components:

[0053] Fatty acid polyethylene glycol esters,

[0054] Sodium dodecyl sulfonate,

[0055] trimethylolpropane tricaprylate,

[0056] Kaolin,

[0057] meerschaum,

[0058] Ethylhexyl Palmitate,

[0059] 2-Mercaptobenzimidazole,

[0060] Polyethylene glycol octadecenyl,

[0061] Oleic acid triethanolamine salt,

[0062] Dioctyl Sebacate,

[0063] Sodium acetate,

[0065] N,N-Dimethylaniline,

[0066] diallyl phthalate,

[0067] Potassium persulfate,

[0068] In terms of parts by weight, the parts by weight of the above components are: 22 parts, 16 parts, 2.5 parts, 0.6 parts, 0.8 parts, 31 parts, 8 parts, 12 parts, 5 parts, 24 parts, 10 parts, 1.2 parts parts, 8 parts, 9.5 parts, 6 parts.

[0069] Among them, the particle size of kaolin is 30-80nm, the particle size of sepiolite is 50-100nm, the particle size of zinc oxide is 60-15...

Embodiment 3

[0076] This embodiment provides a kind of oil agent for pure polyester spinning, comprising following components:

[0077] Fatty acid polyethylene glycol esters,

[0078] Sodium dodecyl sulfonate,

[0079] trimethylolpropane tricaprylate,

[0080] Kaolin,

[0081] meerschaum,

[0082] Ethylhexyl Palmitate,

[0083] 2-Mercaptobenzimidazole,

[0084] Polyethylene glycol octadecenyl,

[0085] Oleic acid triethanolamine salt,

[0086] Dioctyl Sebacate,

[0087] Sodium acetate,

[0088] Zinc oxide,

[0089] N,N-Dimethylaniline,

[0090] diallyl phthalate,

[0091] Potassium persulfate,

[0092] In terms of parts by weight, the parts by weight of the above components are: 23 parts, 13 parts, 2 parts, 0.8 parts, 0.6 parts, 30 parts, 8.5 parts, 13 parts, 6 parts, 23 parts, 10.5 parts, 1.5 parts Servings, 10 servings, 10 servings, 7 servings.

[0093] Among them, the particle size of kaolin is 30-80nm, the particle size of sepiolite is 50-100nm, the particle size of zinc ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com