Bidirectional truss combined board made from composite material and manufacturing method therefor

A composite material and composite board technology, applied in the direction of manufacturing tools, building structures, building components, etc., can solve the problems of poor durability, fire prevention, corrosion resistance, poor sound insulation performance, waste of resources, etc., to achieve excellent comprehensive performance, easy to wear. Pipeline, the effect of solving anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

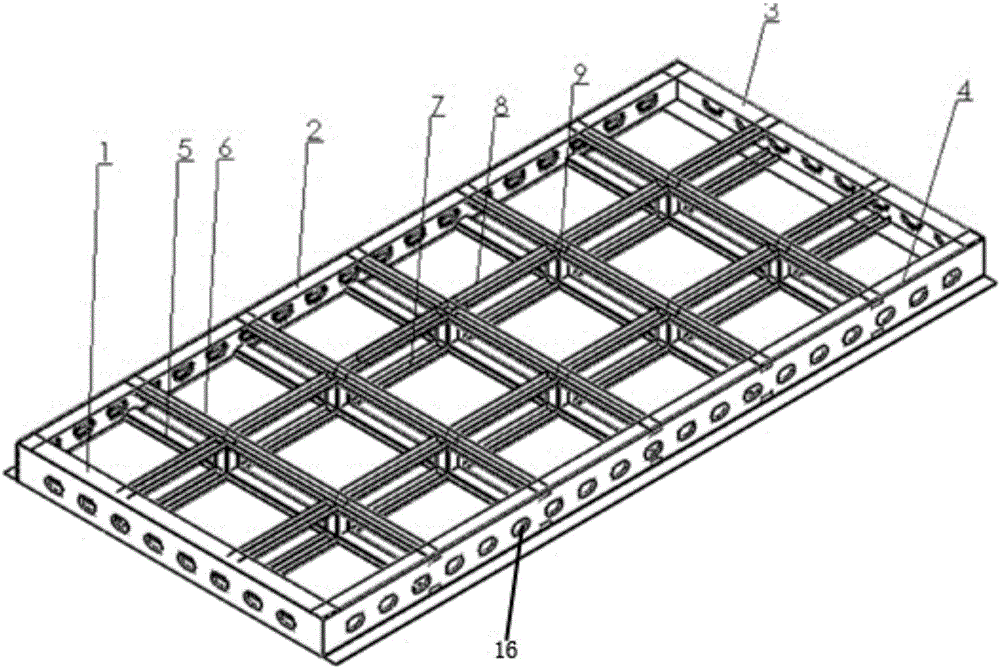

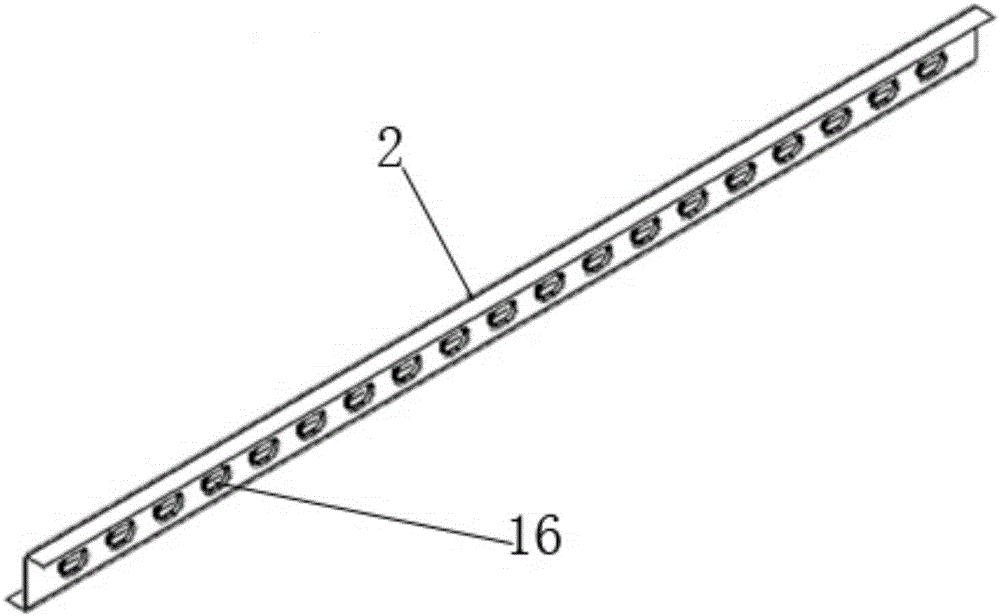

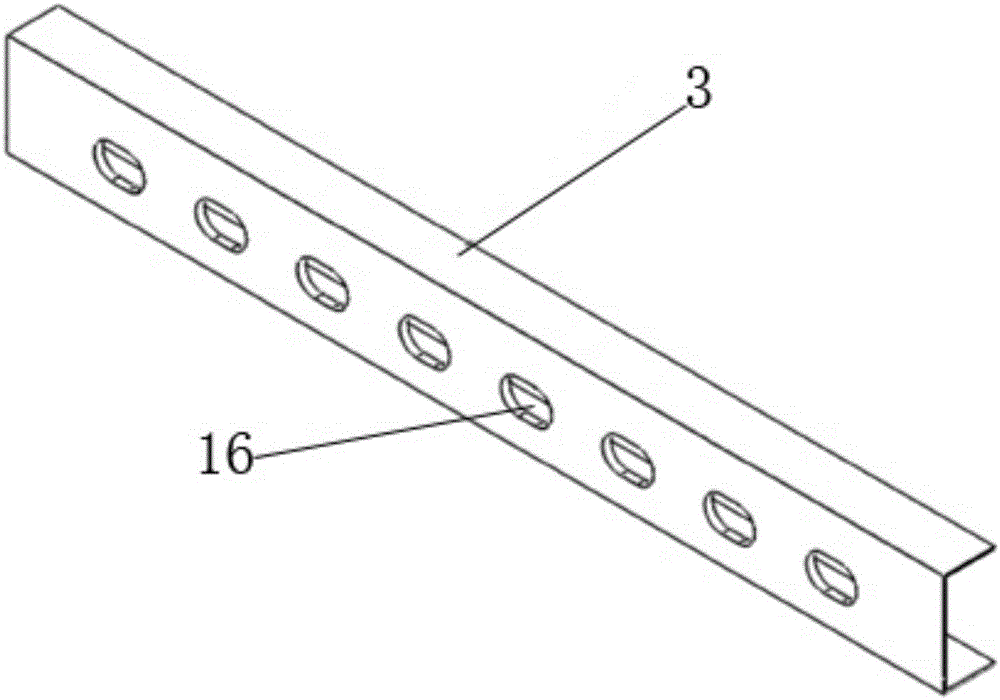

[0042] like Figure 1 to Figure 5 As shown, the present invention provides a composite bidirectional truss composite panel, which is mainly used for floor slabs, roof panels and wall panels, and the composite bidirectional truss composite panel includes a light steel skeleton, an upper layer 10, Lightweight aggregate concrete layer 11, thermal insulation and sound insulation layer 13 and bottom layer 14; thermal insulation and sound insulation layer 13 is located inside the light steel skeleton, the thermal insulation and sound insulation layer is surrounded by the steel skeleton, and the bottom of the thermal insulation and sound insulation layer is laid with glass fiber cloth; the top of the light steel skeleton A light-weight aggregate concrete layer 11 is laid, a steel wire mesh 12 is arranged inside the light-weight aggregate concrete laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com