Signal processing system for carbon baking kiln gas temperature alarm device

A technology of carbon roasting furnace and flue gas temperature, which is applied to fire alarms, thermometers, and measuring devices that rely on smoke/gas effects, and can solve problems such as poor signal processing effects to ensure accuracy and safety , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

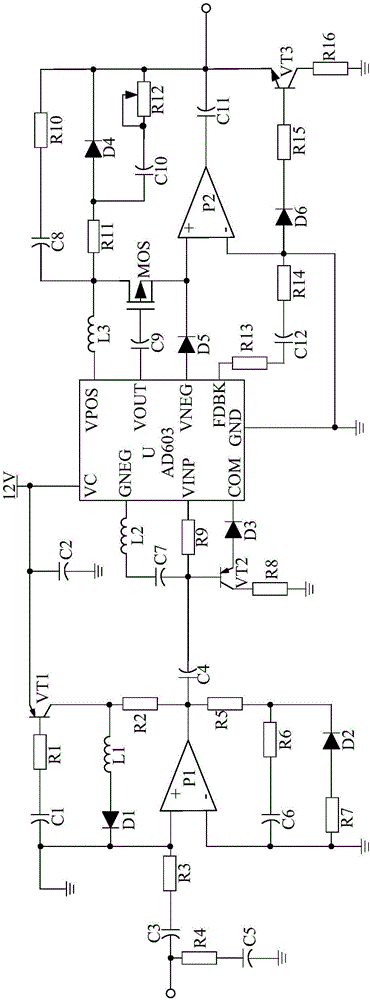

[0017] Such as figure 1 As shown, the present invention is mainly composed of a processing chip U, a transistor VT2, a resistor R8, a resistor R9, a polar capacitor C7, a diode D3, an inductor L2, a signal receiving low-pass filter circuit, and a frequency error correction circuit.

[0018] When connected, the anode of the polarity capacitor C7 is connected to the base of the triode VT2, and the cathode is connected to the GNEG pin of the processing chip U after passing through the inductor L2. One end of the resistor R9 is connected to the VINP pin of the processing chip U, and the other end is connected to the base of the transistor VT2. One end of the resistor R8 is connected to the collector of the transistor VT2, and the other end is grounded. The N pole of the diode D3 is connected to the COM pin of the processing chip U, and the P pole is connected to the emitter of the triode VT2. The signal receiving low-pass filter circuit is respectively connected with the base of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com