Servomotor for ETC and control system thereof

A servo motor and control system technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the problems of low power density and power factor, large grid investment, and waste of electric energy, etc., to achieve power density High, high power factor, the effect of reducing the amount of copper used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

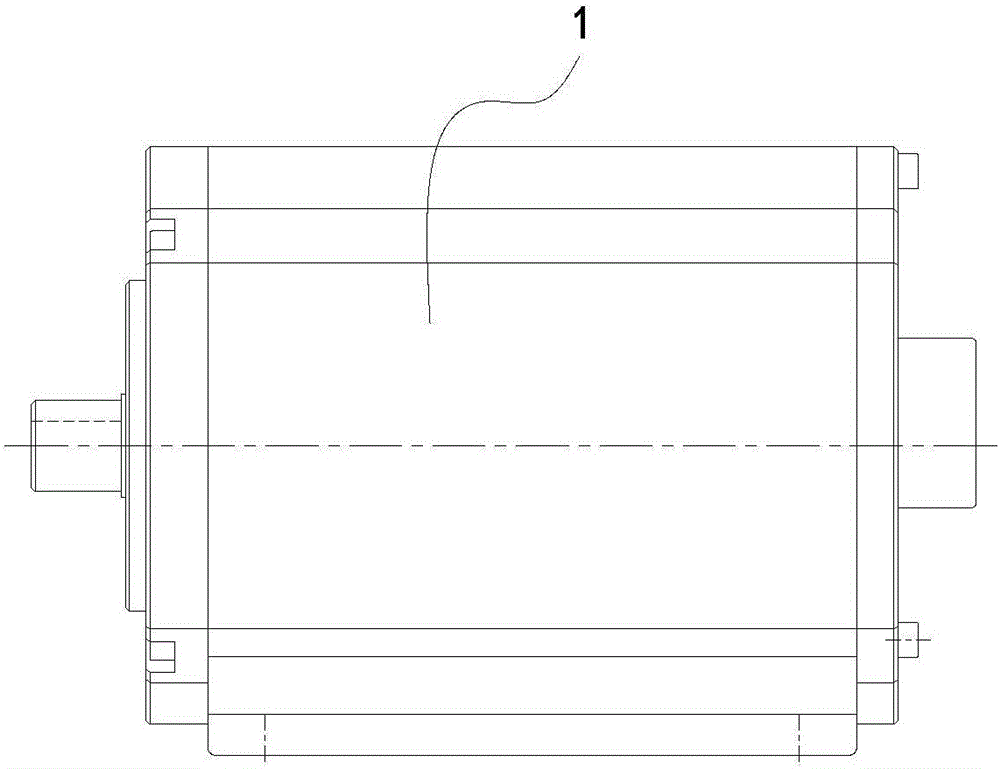

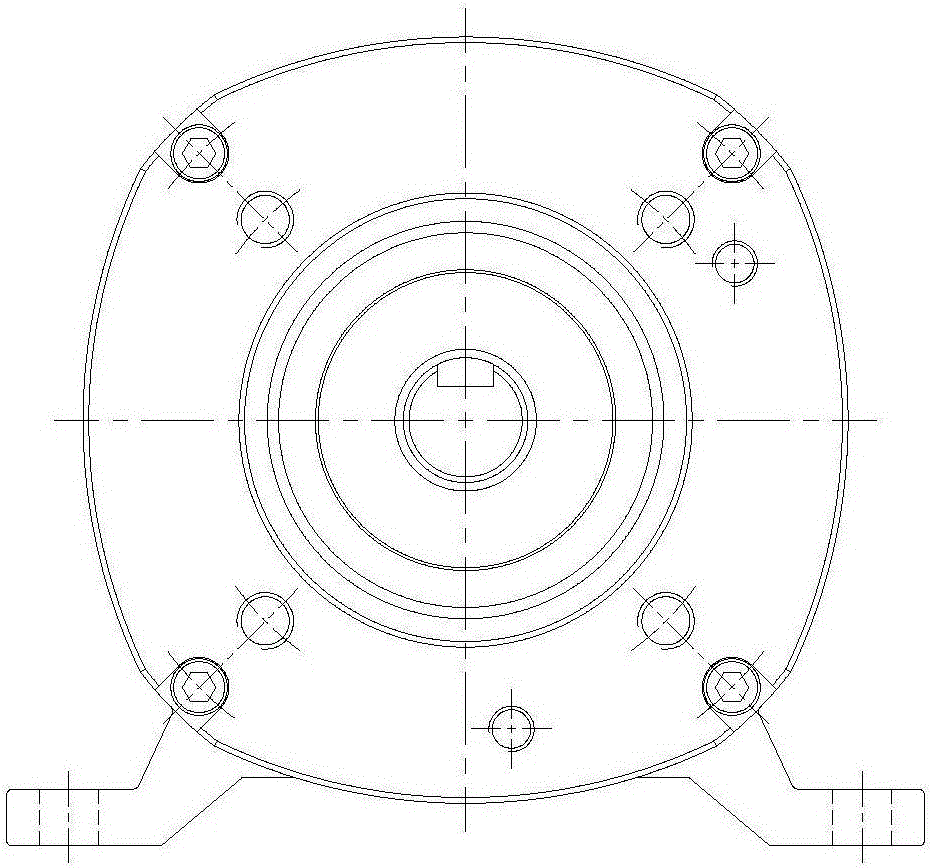

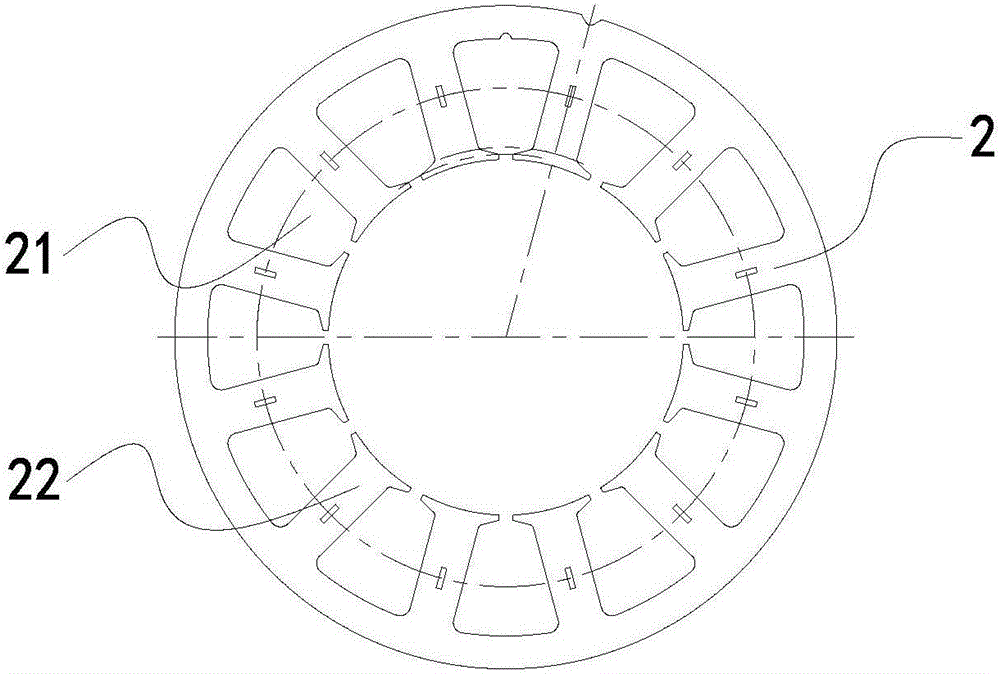

[0027] like Figure 1 to Figure 6 As shown, the servo motor used for ETC includes a motor body, the motor body includes a housing 1, a rotor and a stator are arranged in the housing 1, the rotor has a rotating shaft and a magnet for driving fixed on the rotating shaft, and the stator has a The stator iron core on the outer periphery of the magnet and the windings used to generate the rotating magnetic field, the inner diameter of the stator is 65-69 millimeters, the stator is provided with stator slots 21, the number of stator slots 21 is 10 to 14, and the stator is punched by the stator The sheet 2 is laminated; the rotor is an eccentric magnetic steel rotor with a surface-mounted structure, that is, the magnet is an eccentric magnetic steel 32, and the rotor is provided with rotor slots 31, and the number of rotor slots 31 is 7 to 9. The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com