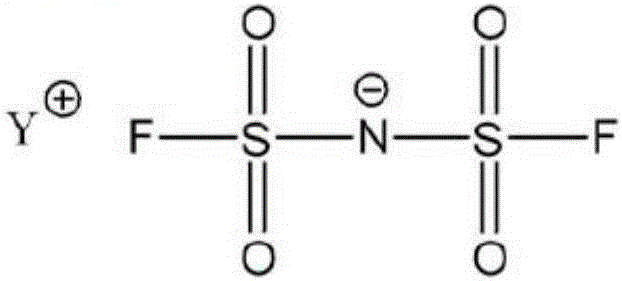

Novel sulfonyl imide salt compound, production method for same, and photoacid generator and light-sensitive resin composition comprising same

A technology of sulfonylimide salt compound and photosensitive resin, which is applied in the direction of nitrogen compounds, chemical instruments and methods, nitrogen and non-metallic compounds, etc., and can solve problems such as high sensitivity that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

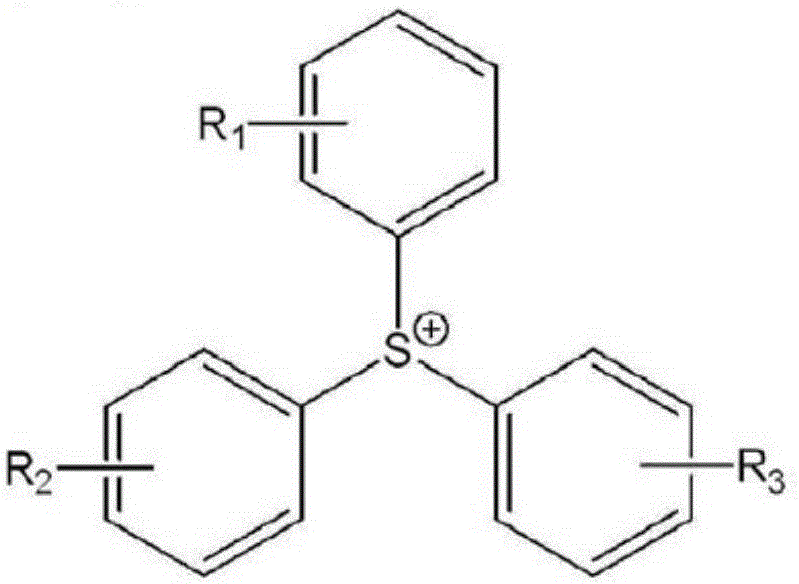

[0208] Synthesis Example 1: Synthesis of Photoacid Generator

[0209] 1-1: Synthesis of photoacid generator a-1

[0210] [Reaction 1]

[0211]

[0212] Triphenylsulfonium bromide (manufactured by TCI Co., Ltd., 34.3 g, 0.1 mol) was dissolved in 200 mL of distilled water, and fluorosulfonimide potassium salt (manufactured by Mitsubishi Chemical Corporation, 32.9 g, 0.15 mol) dissolved in 100 g of distilled water was added. ) solution, stirred at room temperature for 2 hours. After that, extraction was performed using toluene (200 mL), and the toluene layer was evaporated under reduced pressure to remove the solvent to obtain a-1 (44.0 g). This was analyzed with an elemental analyzer (manufactured by Thermo Electron Scientific Instrument, Flash EA1112), and confirmed to be a-1.

[0213] Elemental analysis data: C, 48.71; H, 3.43; N, 3.12; O, 14.49; S, 21.67

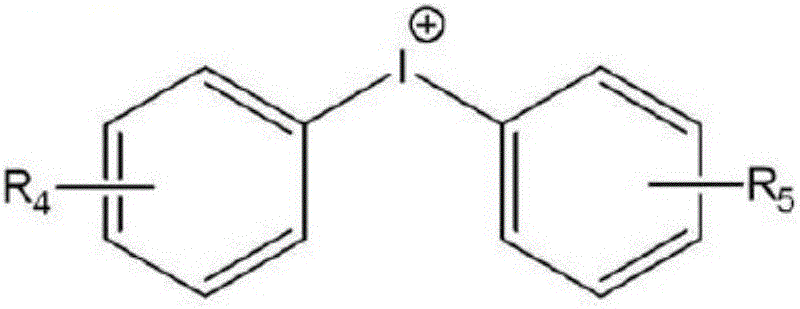

[0214] 1-2: Synthesis of photoacid generator a-2

[0215] [Reaction 2]

[0216]

[0217] Diphenyl iodine ...

experiment example

[0224] (1) Evaluation test of curing rate (reaction rate)

[0225] Using a wire bar, apply the photosensitive resin composition obtained in the foregoing Examples and Comparative Examples to a thickness of 10 μm on glass, and expose it to 100 mJ / cm2 using a high-pressure mercury lamp. 2 light, heat at 80 °C for 10 min. Afterwards, remove a part of the cured film and dissolve it in CDCl 3 The solvent was analyzed by NMR analysis to analyze the content of residual epoxy groups, and the reaction rate was calculated and shown in Table 2.

[0226] Reaction rate = (epoxy content before exposure - epoxy content after exposure) / epoxy content before exposure × 100

[0227] The epoxy content before and after the exposure was calculated and confirmed from the integral of epoxy on the spectrum with respect to the NMR integration of the phenyl group in the molecule.

[0228] (2) Evaluation of color tone after curing

[0229] The color tone of the pattern produced in Experimental ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com