Liquid crystal alignment agent, liquid crystal alignment film and its forming method, liquid crystal display element, polyamic acid and imidized polymer

A technology for liquid crystal display elements and liquid crystal alignment agents, which is applied in the fields of liquid crystal materials, organic chemistry, chemical instruments and methods, etc., can solve the problem of large cumulative exposure, insufficient electrical characteristics and afterimage characteristics of liquid crystal display elements, and insufficient sensitivity. and other problems, to achieve the effects of excellent light sensitivity, excellent electrical characteristics and afterimage characteristics, and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

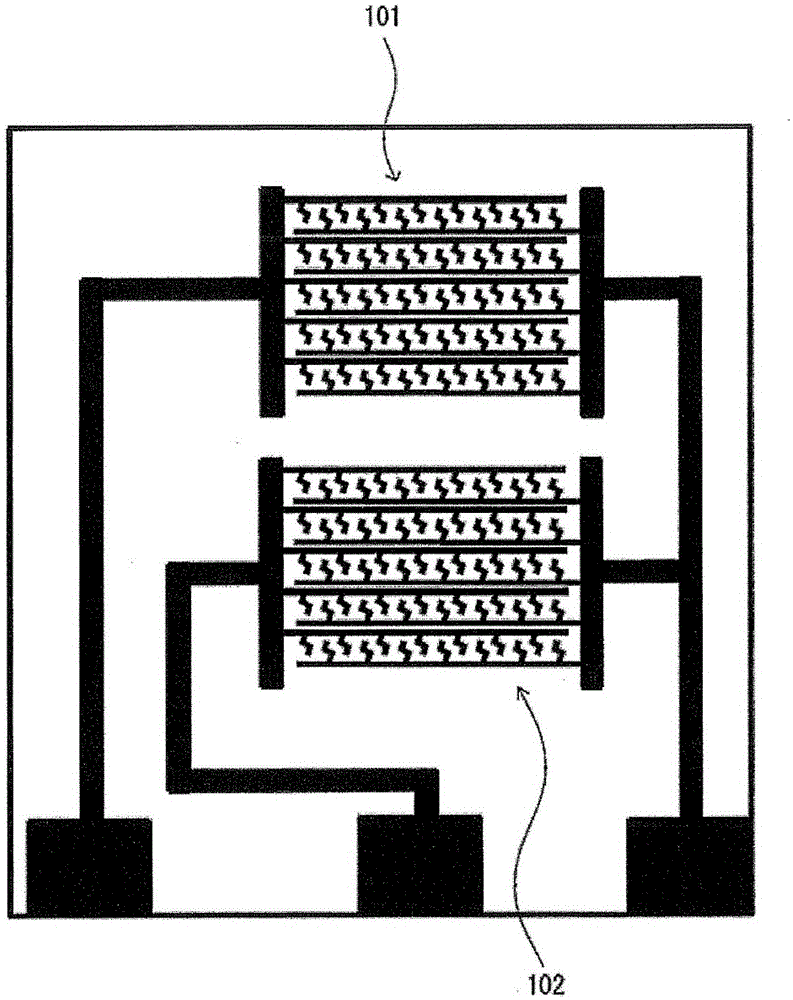

Image

Examples

Embodiment

[0149] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited by these examples.

[0150]

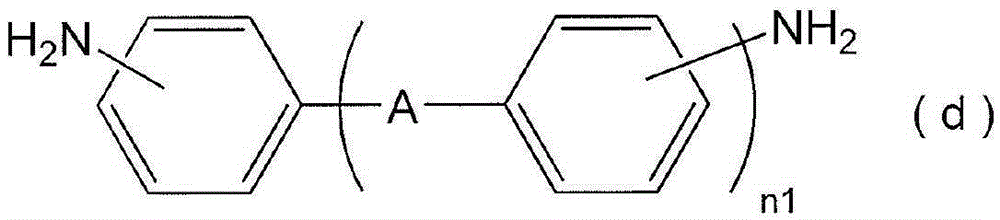

[0151] Synthesis example d-1

[0152] Compound (d1-1) was synthesized according to Scheme 1 below.

[0153] [chemical 7]

[0154]

[0155] Process 1

[0156] (1) Synthesis of compound (d1-1A)

[0157] 171g of 4-nitrothiophenol, 180g of potassium carbonate, and 2L of N,N-dimethylformamide were charged into a 5L three-necked flask with a thermometer and a nitrogen inlet tube, and 216g of 4-nitrobenzyl bromide was added to form The reaction was carried out at room temperature for 2 hours. After completion of the reaction, 10 L of ethyl acetate was added to the reaction mixture, followed by liquid separation washing with dilute hydrochloric acid and water. After drying the organic layer with magnesium sulfate, the solid obtained by removing the solvent under reduced pressure was recrystallized with ethano...

Embodiment 1

[0204] N-methyl was added to a polymer solution containing the polyamic acid (P-1) obtained in Synthesis Example p-1 above (the amount corresponding to 100 parts by weight in terms of polyamic acid solids) -2-pyrrolidone (N-methyl-2-pyrrolidone, NMP) and butyl cellosolve (ButylCellosolve, BC), further adding N,N,N',N'-tetraglycidyl-4,4 20 parts by weight of '-diaminodiphenylmethane was fully stirred to obtain a solution having a solvent composition of NMP:BC=60:40 (weight ratio) and a solid content concentration of 2.5% by weight. This solution was filtered using a filter with a pore diameter of 1 μm, thereby preparing a liquid crystal alignment agent (A-1).

Embodiment 2~ Embodiment 8 and comparative example 1 and comparative example 2

[0206] In the above-mentioned Example 1, except that the polymer described in Table 1 was used instead of the polyamic acid (P-1) as the polymer, the liquid crystal alignment agent (A-2) was prepared in the same manner as in Example 1, respectively. )~liquid crystal alignment agent (A-8), liquid crystal alignment agent (B-1) and liquid crystal alignment agent (B-2).

[0207] Using each of the liquid crystal alignment agents prepared in the above-mentioned examples and comparative examples, a liquid crystal display element was manufactured as follows, and evaluated.

[0208] All results are shown in Table 1.

[0209]

[0210] Use a spinner to apply each liquid crystal alignment agent prepared above on the transparent electrode surface of a glass substrate with a transparent electrode including an ITO film, and heat (pre-baked) on a hot plate at 80° C. for 1 minute. It heated (post-baked) for 1 hour in the clean oven of 200 degreeC, and formed the coating film with a film thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com