Combined type crystallizer water jacket and machining method thereof

A combined type and crystallizer technology, which is applied in the field of metal continuous casting equipment and its processing, can solve the problems of reducing the service life of the water jacket, inconsistent shell thickness, and affecting cooling performance, so as to save labor costs, good welding quality, and energy saving The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

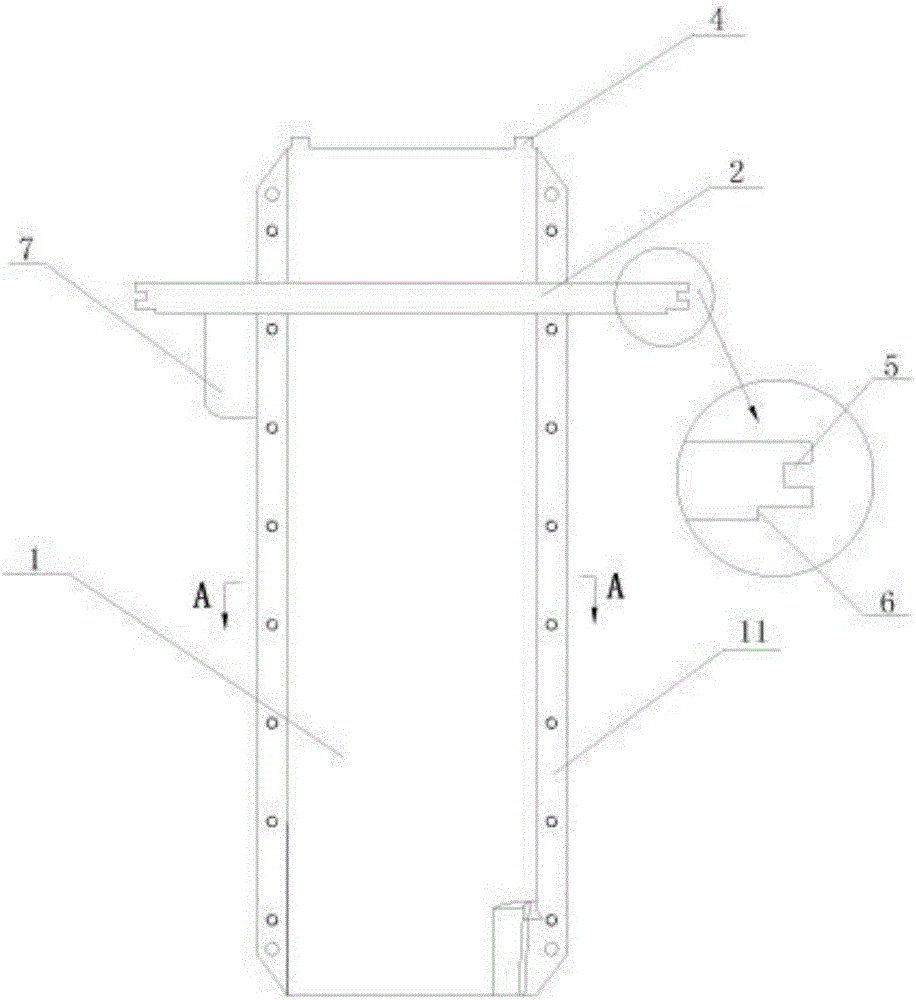

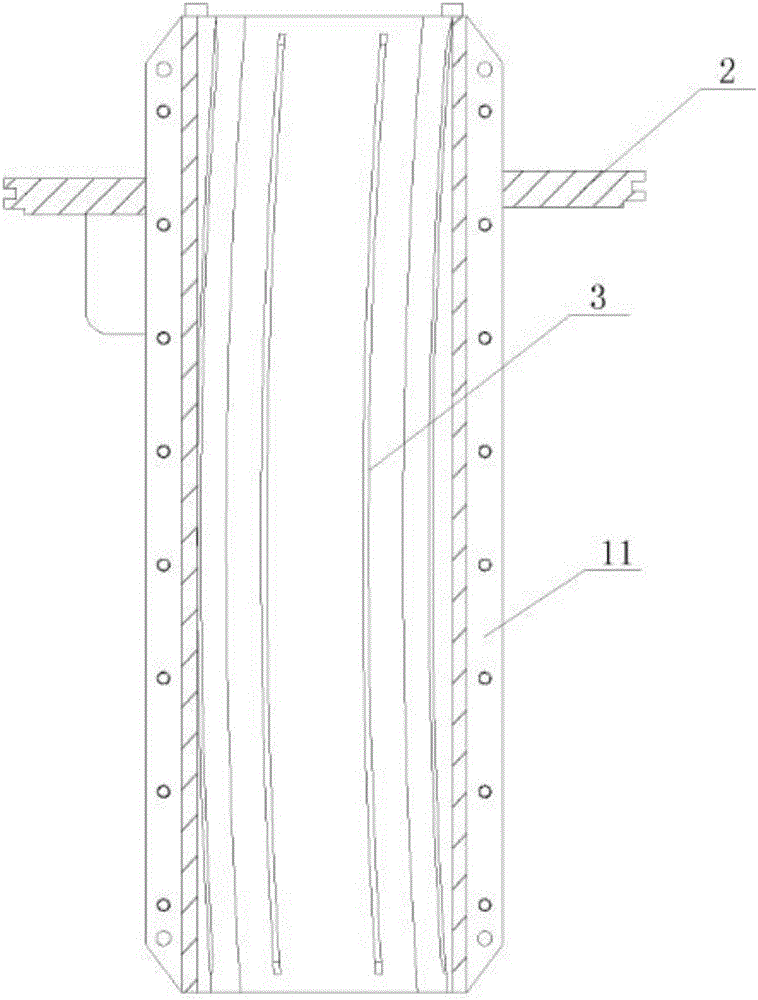

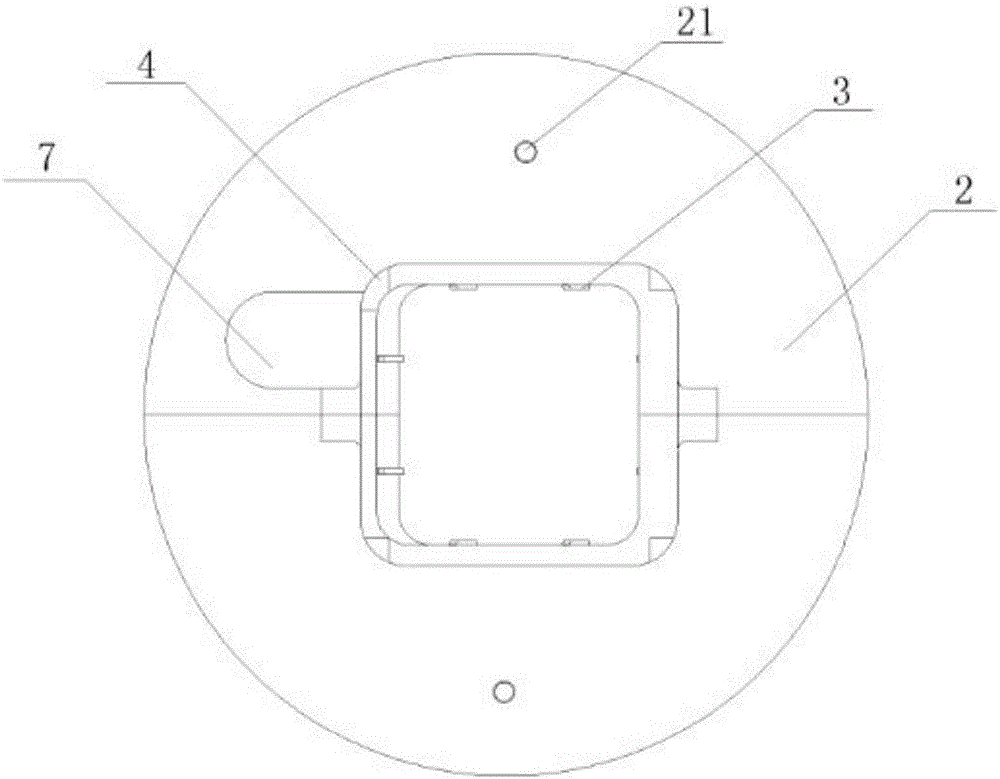

[0034] See Figure 1 to Figure 4 A combined crystallizer water in the present invention includes a hollow arc-shaped stainless steel water jacket body 1 and an annular fixed partition 2 fixedly sleeved on the outer ring of the upper part of the water jacket body. The fixed partition 2 surrounds the fixed partition in a circle. The outer ring of the plate 2, the fixed partition 2 is an annular plate whose outer contour is circular and the shape of the ring hole matches the outer contour of the water jacket body 1. The fixed partition 2 is formed by butting two half-rings, along the The inner wall of the main body is provided with a plurality of diversion positioning water strips 3, and the water jacket main body 1 is formed by two stainless steel tanks bent by CNC machining, and the flanging 11 extending outward along the opening in the length direction is connected by bolts , The flange 11 is provided with threaded holes. The cross-section of the water jacket body 1 is genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com