Preparation technique for magnetostriction TC4 alloy bar special for dental department

A technology of magnetostrictive dentistry and alloy rods, which is applied in dentistry, medical science, etc., can solve the problems that the effect of vibration cannot be guaranteed, and the vibration requirements of the working head of magnetostrictive dental treatment can not be satisfied, so as to achieve good plasticity matching and material The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in combination with specific embodiments.

[0023] A preparation process for magnetostrictive dental special TC4 alloy rods, comprising the following steps:

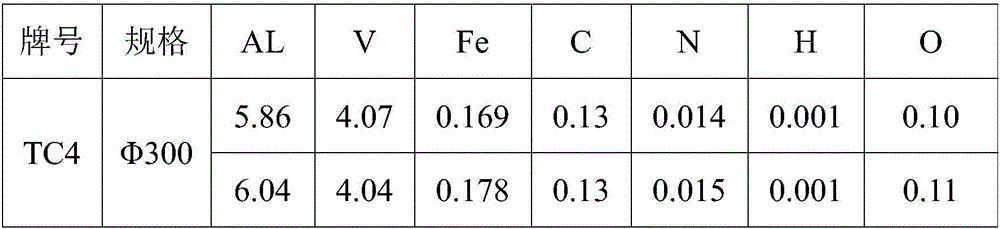

[0024] Step 1. Melting ingot

[0025] "Grade 0" titanium sponge is selected as the raw material, pure AL beans and AL85V particles are used as alloying elements, ingredients are formulated according to the famous alloy composition of TC4 brand, the electrodes are pressed, and Φ300*Lmm ingots are smelted three times in a vacuum consumable electric arc furnace;

[0026] Step 2. Blank forging

[0027] The ingot is heated to the β-phase region by an electric furnace, kept warm to make it completely burnt through, and multi-directional forged under the high pressure of a 2500t hydraulic press, deformed to a square billet of 120mm*120mm*Lmm;

[0028] Step three, hot rolling

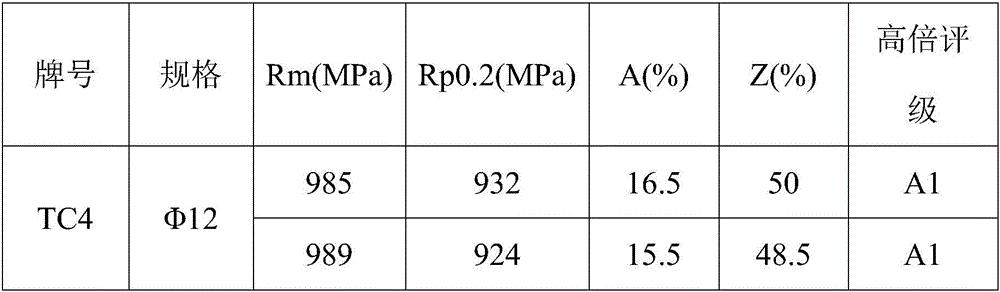

[0029] Heat the above-mentioned square billet in a resistance furnace (α+β two-phase re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com