A method for producing sterile purified water and a reverse osmosis water purifier using the method

A water purifier and reverse osmosis technology, applied in the field of water purification, can solve the problems of human injury, inability to inhibit bacterial growth, excessive bacterial content, etc., and achieve the effect of ensuring quality and eliminating bacterial pollution and breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

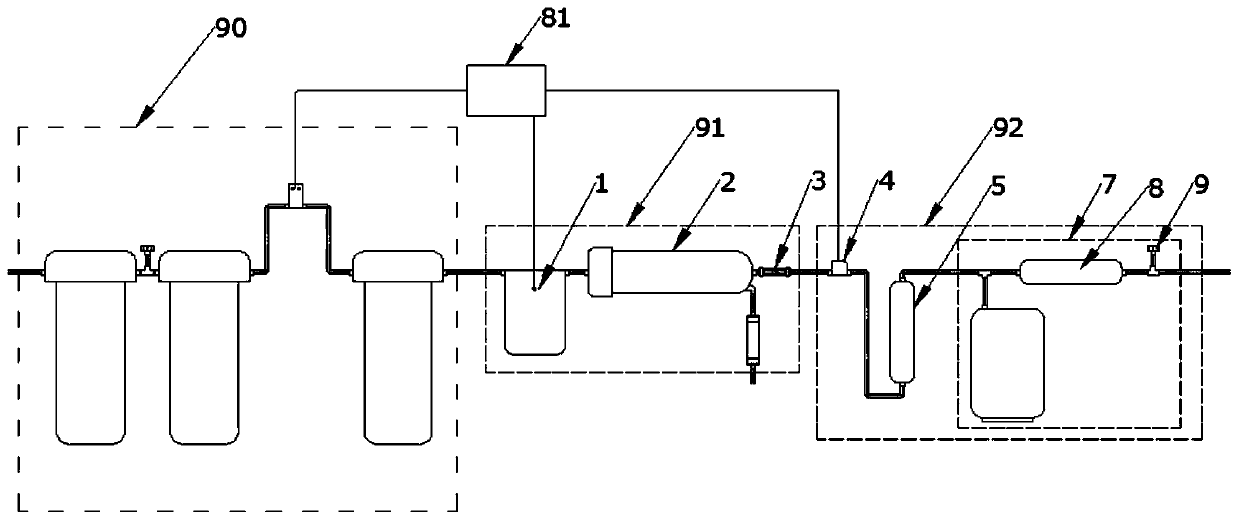

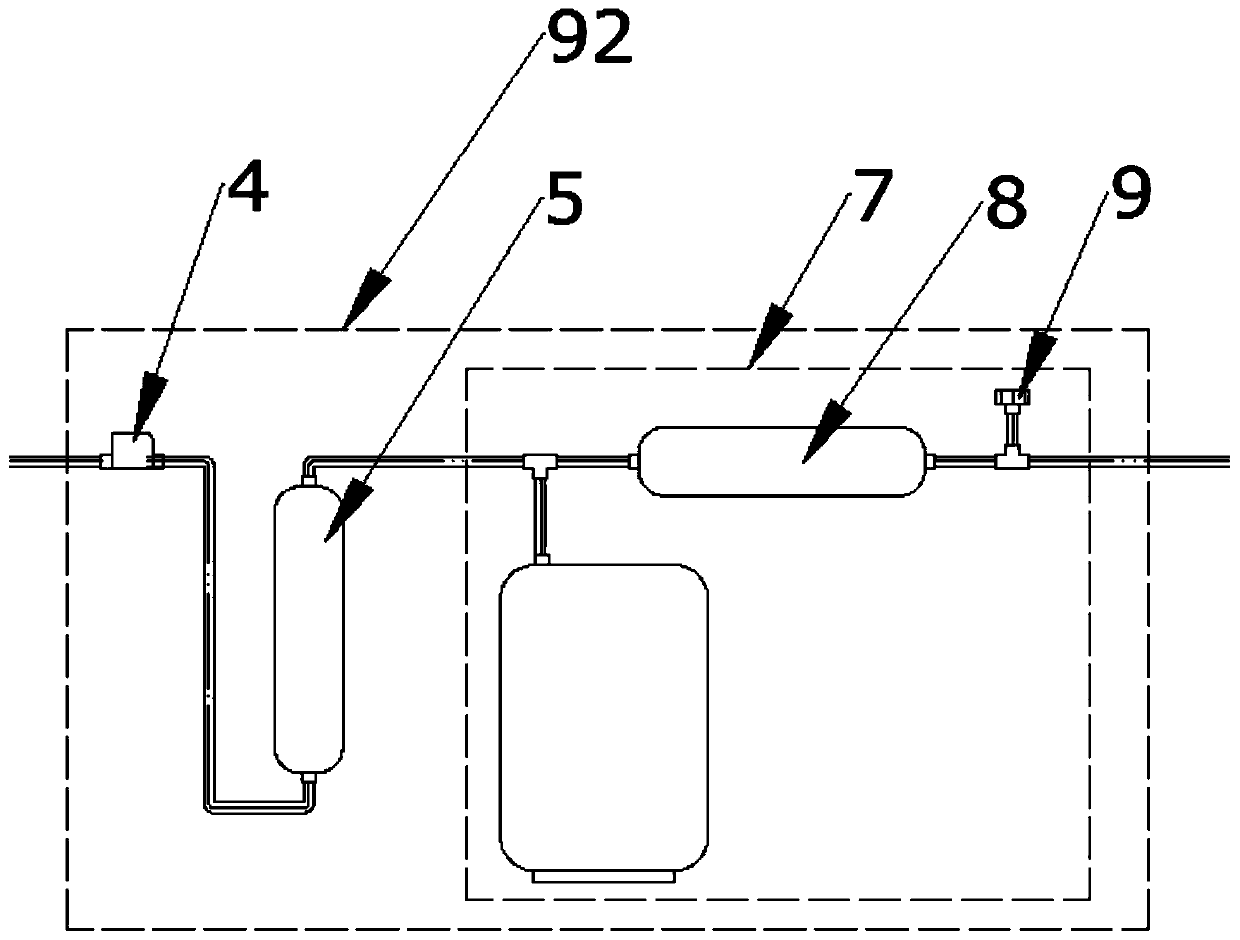

[0034] The present invention provides a method for preparing sterile purified water, specifically including a closed sterilization unit 92, the sterilization unit 92 includes a sterilization filter 5 and a water purification storage and discharge unit 7, the front end of the sterilization filter 5 Connected to the clean water outlet of the bacteria isolation unit 91, the rear end of the sterilization filter element 5 is connected to the clean water storage and discharge unit 7. The clean water storage and discharge unit 7 includes a water purification faucet 9. The sterilization material in the sterilization filter element 5 is A food-grade, water-soluble broad-spectrum sterilization material, the method includes the following steps:

[0035] S1, sterilization; the water purification faucet 9 is closed, the purified water flowing through the bacteria isolation unit 91 flows into the sterilization unit 92, and dissolves the sterilization material in the sterilization filter 5 to fo...

Embodiment 2

[0050] Such as figure 1 with 2 As shown, the present invention provides a reverse osmosis water purifier using this method for preparing sterile water purification, including a pre-filter unit 90 and a control board 81, and an active water inlet is provided at the front end of the pre-filter unit 90 , The rear end of the pre-filter unit 90 is connected to the front end of the bacteria isolation unit 91, and the control board 81 is electrically connected to the high-voltage switch 4. The control board 81 can detect the state of the high-pressure switch 4 and thereby control the start and stop of the booster pump 1.

[0051] By setting up the pre-filtration unit 90, the source water can be subjected to preliminary filtration and purification treatment to reduce the working pressure of the reverse osmosis membrane unit 2, improve the efficiency of the reverse osmosis membrane unit 2 in isolating bacteria and producing purified water, and extend the reverse osmosis membrane The servi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com