Method for treating excess sludge of sewage plant

A treatment method and technology for excess sludge, which can be used in sludge treatment, dewatering/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc. Large, lower processing costs, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

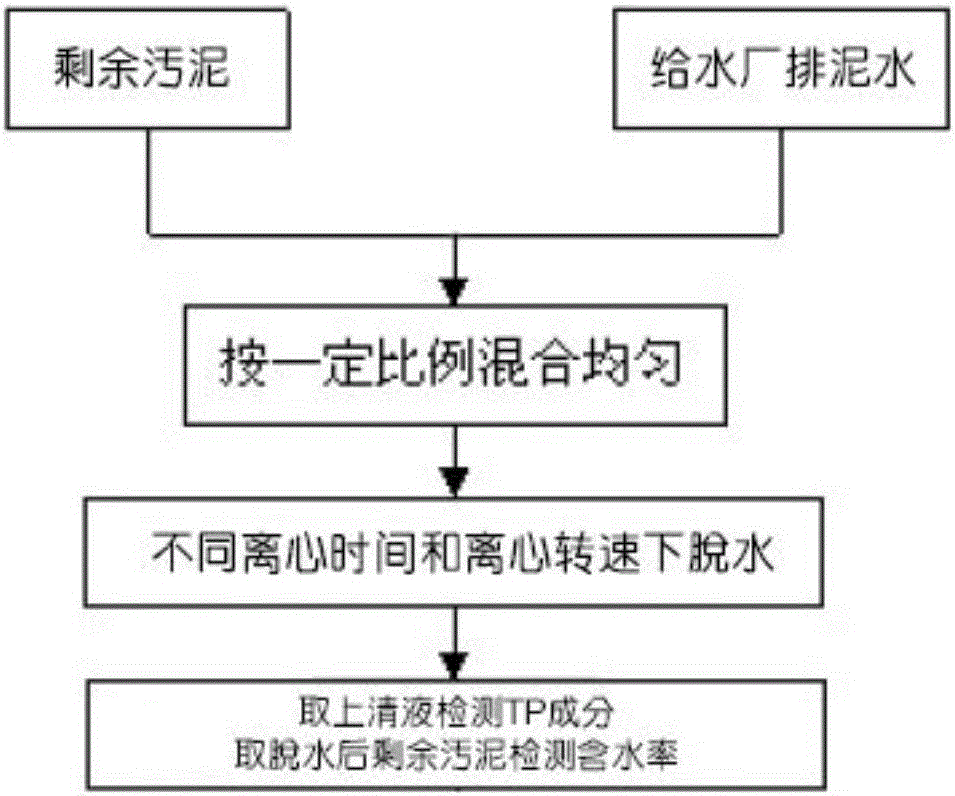

[0044] The present invention is a method for dehydrating and dephosphorizing the excess sludge of a sewage plant by using the sludge discharge water from an urban water supply plant. The process steps are as follows: figure 1 As shown, the details are as follows:

[0045] (1) Pour the undehydrated remaining sludge from the sewage plant into a 1L beaker and stir evenly;

[0046] (2) Measure 100ml-300ml of water supply plant sludge and put it into the undehydrated excess sludge, and stir it evenly with a magnetic stirrer;

[0047] (3) Place the stirred mixed sludge (the remaining sludge added to the sludge of the water supply plant) in a centrifuge, and centrifuge and dehydrate at a speed of 2600r / min to 3800r / min for 10min to 30min;

[0048] (4) Take the same amount of remaining sludge that has not been added to the water supply plant sludge and place it in a centrifuge for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com