Process for preparing cyclohexanone by cyclohexanol dehydrogenation

A technology of cyclohexanol and cyclohexanone, which is applied in the field of preparation of cyclohexanone, can solve problems such as unqualified product quality, achieve the effects of reducing circulation and accumulation, reducing side reactions, and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

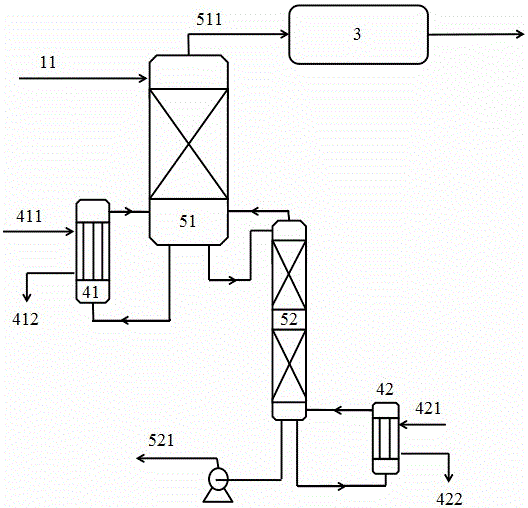

[0039] Such as figure 2 As shown, it is a schematic diagram of the equipment and flow chart of the cyclohexanol dehydrogenation process in the newly built 100,000 tons / year cyclohexanol dehydrogenation process to prepare cyclohexanone in a certain factory. The equipment of the cyclohexanol dehydrogenation process in the described technology is made up of 1# normal pressure deheptanone tower 51, 2# normal pressure deheptanone tower 52 and cyclohexanol dehydrogenation reactor 3; Pressure removal heptanone tower 51 and 2# atmospheric pressure removal heptanone tower 52 are only provided with a stripping section, and the bottom of the still is respectively provided with 1# reboiler 41 and 2# reboiler 42; Heptanone tower 51 and 2# normal pressure deheptanone tower 52 are two towers connected in series, both are plate wave packed towers, the minimum theoretical total number of plates is calculated as 26 by the following method, wherein, 1# normal pressure deheptanone The actual pl...

Embodiment 2

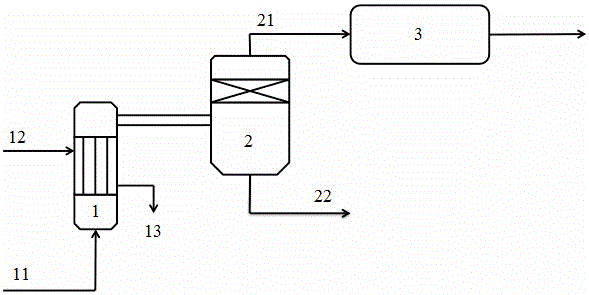

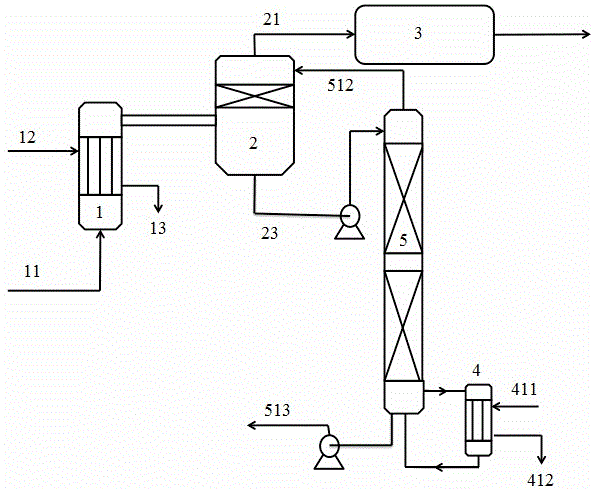

[0051] Such as image 3 As shown, it is a schematic diagram of the equipment and flow chart of the cyclohexanol dehydrogenation process in the process of preparing cyclohexanone from cyclohexanol dehydrogenation of 100,000 tons per year after the transformation of the existing equipment in a certain factory. The equipment of the cyclohexanol dehydrogenation process in the described technology is made up of cyclohexanol evaporator 1, gas-liquid separator 2, normal pressure removing heptanone tower 5 and cyclohexanol dehydrogenation reactor 3, promptly in existing Device (such as the comparative example) between the gas-liquid separator 2 and the cyclohexanol dehydrogenation reactor 3, an atmospheric pressure heptanone removal tower 5 is added; the atmospheric pressure heptanone removal tower 5 is only provided with a stripping section, and the bottom A reboiler 4 is provided; the atmospheric pressure deheptanone tower 5 is a plate-wave packing single tower, and the minimum theo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com